Table of Contents

What is Zirconia Sintering Furnace

A zirconia sintering furnace is a specialized piece of equipment used in the dental and jewelry industries for the sintering or firing of zirconia ceramic materials. Zirconia is a high-performance ceramic that possesses excellent strength, durability, and aesthetic properties, making it a popular choice for dental crowns, bridges, and other dental restorations, as well as for jewelry.

The sintering process involves heating zirconia ceramic at high temperatures to induce particle bonding and achieve densification. This results in a strong and durable material with the desired properties. The zirconia sintering furnace provides the controlled environment necessary for the sintering process.

Here are some key features and components typically found in a zirconia sintering furnace:

Heating elements: These are responsible for generating the heat required for sintering. Commonly used heating elements include molybdenum disilicide (MoSi2) or silicon carbide (SiC) rods.

Temperature control system: The furnace is equipped with a sophisticated temperature control system that ensures precise and consistent temperature management throughout the sintering process. This system may use thermocouples or other temperature sensors to monitor and regulate the furnace temperature.

Insulation: The furnace chamber is lined with high-quality insulation materials to minimize heat loss and maintain a stable temperature environment inside the furnace.

Programmable settings: Zirconia sintering furnaces often come with programmable settings, allowing users to define temperature profiles and heating/cooling cycles based on specific material requirements. This flexibility enables the optimization of sintering parameters for different zirconia compositions.

Safety features: To ensure safe operation, zirconia sintering furnaces are equipped with safety features such as over-temperature protection, and ventilation systems to remove any potentially hazardous byproducts.

What is the working principle of zirconia sintering furnace?

The working principle of a zirconia sintering furnace revolves around the application of controlled heat to the zirconia material, facilitating its densification and bonding. Here’s a general overview of the working principle of a zirconia sintering furnace:

Heating Elements: The furnace contains heating elements, typically made of high-temperature resistant materials such as molybdenum disilicide (MoSi2) or silicon carbide (SiC). These heating elements generate and emit heat when an electric current passes through them.

Temperature Control: The furnace is equipped with a temperature control system that allows precise regulation of the heating elements. The temperature control system monitors and adjusts the furnace temperature according to the desired sintering parameters.

Loading and Chamber: The zirconia material, in the form of zirconia powder or pre-sintered zirconia blocks, is loaded into the furnace chamber. The chamber is designed to provide a controlled environment for the sintering process, including uniform heat distribution and insulation.

Heating Stage: The furnace is activated, and the heating elements start generating heat. The temperature gradually increases to the desired sintering temperature based on the preset parameters. The heating rate and temperature profile may vary depending on the specific zirconia material and furnace design.

Dwell or Soaking Stage: Once the desired sintering temperature is reached, the furnace maintains the temperature for a certain period, known as the dwell or soaking time. This stage allows for the diffusion and bonding of the zirconia particles, promoting densification and the development of desired material properties.

Cooling Stage: After the dwell time, the furnace initiates the cooling process. The cooling rate is controlled to prevent rapid temperature changes that could cause thermal stress or cracking in the sintered zirconia. The furnace gradually reduces the temperature to a safe level.

Unloading: Once the cooling process is complete and the temperature has sufficiently dropped, the sintered zirconia is ready for removal from the furnace. Care should be taken to handle the material safely, as it may still be hot.

The working principle of a zirconia sintering furnace is to provide controlled heating and cooling cycles, allowing for the proper bonding and densification of zirconia particles. The furnace’s temperature control system, heating elements, and chamber design work together to create an environment conducive to achieving the desired sintering results.

It’s important to note that the working principles of zirconia sintering furnaces may vary depending on the specific furnace model, design, and manufacturer. It’s recommended to refer to the manufacturer’s instructions and guidelines for the precise working principles and operation of your specific zirconia sintering furnace.

Applications of Zirconia Sintering Furnace

The primary application of a zirconia sintering furnace is in the dental and jewelry industries for the fabrication of dental restorations and jewelry components using zirconia ceramic materials. Here are some specific applications:

Dental Restorations: Zirconia sintering furnaces are commonly used in dental laboratories for the sintering of zirconia ceramic blocks or discs used in the production of dental crowns, bridges, inlays, onlays, and implant abutments. The furnace ensures that the zirconia material reaches its optimal strength, durability, and aesthetic properties.

Jewelry Manufacturing: Zirconia is also used in the jewelry industry for the production of high-quality, durable, and aesthetically pleasing jewelry pieces. Zirconia sintering furnaces enable the sintering of zirconia powders or pre-formed components to create intricate jewelry designs and ensure the desired hardness and appearance.

Research and Development: Zirconia sintering furnaces are utilized in research and development settings to investigate and optimize the properties of zirconia ceramics. Researchers may experiment with different sintering parameters, such as temperature profiles and atmosphere conditions, to achieve specific material characteristics for various applications beyond dentistry and jewelry.

It’s worth noting that while zirconia sintering furnaces are primarily associated with dental and jewelry applications, they can also be used in other industries where zirconia ceramics are utilized, such as aerospace, electronics, and biomedical fields, where high-strength, biocompatible materials are required.

Benefit of Zirconia Sintering Furnace

The use of a zirconia sintering furnace offers several benefits, particularly in the dental and jewelry industries. Here are some key advantages:

High-Strength and Durability: Zirconia ceramics produced through the sintering process in a specialized furnace exhibit exceptional strength and durability. This makes them suitable for demanding applications where materials need to withstand forces, wear, and abrasion, such as dental restorations or jewelry components.

Aesthetic Appeal: Zirconia ceramics can be fabricated to closely resemble natural teeth or achieve desired jewelry designs. The sintering process allows for the production of highly aesthetic restorations or jewelry pieces with excellent color stability, translucency, and natural-looking characteristics.

Biocompatibility: Zirconia is a biocompatible material, meaning it is well-tolerated by the human body. In dental applications, zirconia restorations offer a non-allergenic and tissue-friendly alternative to traditional metal-based restorations. This promotes healthier gum tissue and reduces the risk of adverse reactions.

Precision and Accuracy: Zirconia sintering furnaces are equipped with advanced temperature control systems, enabling precise and consistent heating profiles. This level of control ensures that the sintering process is accurately executed, resulting in reliable and predictable material properties. This is crucial for achieving the desired fit, functionality, and longevity of dental restorations or jewelry components.

Time and Cost Efficiency: Zirconia sintering furnaces are designed to provide efficient and rapid sintering cycles, allowing for faster production turnaround times in dental laboratories or jewelry manufacturing facilities. Additionally, zirconia ceramics eliminate the need for labor-intensive and costly traditional metal casting processes, leading to potential cost savings.

Versatility: Zirconia sintering furnaces offer flexibility in terms of accommodating different zirconia compositions and shapes. They can handle a wide range of zirconia materials, including various shades and translucencies, enabling customization based on patient or customer preferences.

Consistency and Reproducibility: The controlled sintering environment provided by these furnaces ensures consistent and reproducible material properties across multiple production cycles. This is important for maintaining quality standards and meeting specific requirements in dental and jewelry applications.

Overall, the use of a zirconia sintering furnace enhances the quality, performance, and aesthetic outcomes of zirconia ceramic materials, making them a preferred choice in dental restorations, jewelry manufacturing, and other industries that demand high-performance ceramics.

Zirconia Sintering Furnace Price

The price of a zirconia sintering furnace can vary significantly based on several factors, including the brand, model, specifications, features, and the supplier or distributor. Additionally, the price may also depend on the country or region where the furnace is being purchased.

Generally, zirconia sintering furnaces can range in price from a few thousand dollars to tens of thousands of dollars. Higher-end furnaces with advanced features and larger capacities tend to be more expensive.

If you are interested in purchasing a zirconia sintering furnace, we recommend contacting us directly to inquire about the price. We can provide detailed information and a free quote based on your specific requirements.

Keep in mind that in addition to the upfront cost of the furnace, you should consider factors such as warranty, technical support, and ongoing maintenance expenses when evaluating the overall value of the equipment.

How to choose a zirconia sintering furnace supplier?

Choosing the right zirconia sintering furnace supplier is crucial to ensure you get a reliable product and excellent service. Here are some factors to consider when selecting a supplier:

1. Reputation and Experience: Look for suppliers with a strong reputation and extensive experience in the industry. Consider how long they have been in business and their track record of delivering quality products and services.

2. Product Quality and Reliability: Evaluate the quality and reliability of the zirconia sintering furnaces offered by the supplier. Check if they meet industry standards and have positive reviews from customers. It’s also beneficial to inquire about the manufacturers they represent and the certifications the furnaces hold.

3. Range of Products and Options: Consider the supplier’s range of zirconia sintering furnaces. Do they offer different models with varying features, sizes, and capacities? Having options allows you to choose a furnace that best suits your specific needs.

4. Technical Support and Service: Find out what type of technical support and service the supplier provides. Do they offer installation assistance, training, and troubleshooting support? Having access to knowledgeable support staff can be valuable when you have questions or need assistance with the furnace.

5. Pricing and Value: Compare pricing from different suppliers, keeping in mind the features and quality of the furnaces they offer. Look for a supplier that provides good value for your investment. Consider factors such as warranty, maintenance services, and any additional benefits they offer.

6. Customer Reviews and References: Read customer reviews and testimonials to gauge the experiences of other customers with the supplier. Additionally, ask the supplier for references or case studies from existing customers who have used their zirconia sintering furnaces.

7. After-Sales Support: Inquire about the supplier’s after-sales support. Do they provide ongoing maintenance services, spare parts availability, and upgrades if needed? Having reliable after-sales support ensures the longevity and performance of your furnace.

8. Local Availability and Logistics: Consider the supplier’s location and their ability to deliver and support the equipment in your region. Look for a supplier that can provide prompt delivery, easy communication, and efficient logistics.

9. Industry Relationships and Affiliations: Suppliers who have strong relationships with industry organizations, dental laboratories, or manufacturers can be advantageous. They may have access to the latest technologies, trends, and training resources.

10. Personalized Consultation and Recommendations: A good supplier should be willing to understand your specific needs and provide personalized consultation. They should recommend the most suitable zirconia sintering furnace based on your requirements, budget, and goals.

By considering these factors and conducting thorough research, you can make an informed decision when selecting a zirconia sintering furnace supplier that meets your needs and provides reliable products and services.

What is the process of sintering zirconia?

The process of sintering zirconia involves subjecting the zirconia material to high temperatures to induce a controlled bonding and densification of the particles. Here is a general overview of the steps involved in the sintering process for zirconia:

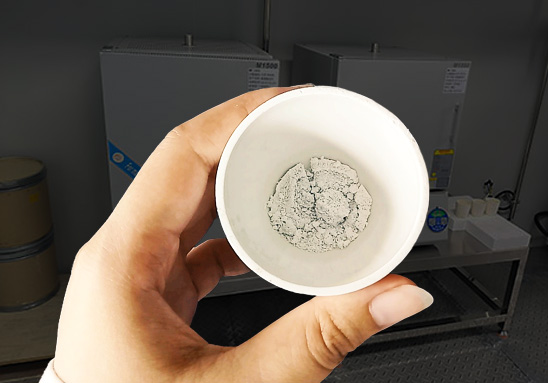

1. Preparation of Zirconia Material: Start by preparing the zirconia material in the desired form, such as zirconia powder or pre-sintered zirconia blocks. The zirconia material should be properly shaped and sized for the intended application.

2. Loading the Zirconia into the Furnace: Place the prepared zirconia material into the zirconia sintering furnace. Ensure that the material is evenly distributed within the furnace chamber and that there is sufficient space for proper heat circulation.

3. Setting the Sintering Parameters: Set the sintering parameters on the furnace, including temperature, heating rate, dwell time, and cooling rate. These parameters may vary depending on the specific zirconia material, manufacturer recommendations, and desired material properties.

4. Heating Stage: Start the heating process by gradually increasing the temperature inside the furnace. The temperature should be raised according to a predetermined heating rate to prevent thermal shock and cracking. The temperature is typically elevated to a specific range suitable for the sintering of zirconia, usually between 1300°C and 1600°C.

5. Dwell or Soaking Stage: Once the desired sintering temperature is reached, the furnace maintains that temperature for a certain period, known as the dwell or soaking time. This stage allows for the diffusion and bonding of the zirconia particles, promoting densification and the development of desired material properties.

6. Cooling Stage: After the dwell time, the furnace initiates the cooling process. The cooling rate is typically controlled to prevent rapid temperature changes that could cause thermal stress or cracking in the sintered zirconia.

7. Removal from the Furnace: Once the cooling process is complete and the temperature has sufficiently dropped, the sintered zirconia is removed from the furnace. Take care to handle the material properly, as it may still be hot.

8. Post-Sintering Processing: Depending on the specific application, the sintered zirconia may undergo additional processing steps, such as machining, polishing, or characterization, to achieve the desired final shape, fit, and surface finish.

It’s important to note that the sintering process parameters may vary depending on the specific zirconia material, furnace specifications, and the manufacturer’s recommendations. It’s advisable to refer to the manufacturer’s instructions and guidelines for the precise sintering process parameters required for the particular zirconia material you are working with.

FAQ of Zirconia Sintering Furnace

Q1: What is the sintering temperature for zirconia ceramics?

A1: The sintering temperature for zirconia ceramics typically ranges from 1350°C to 1550°C, depending on the specific composition and requirements of the material being used.

Q2: How long does the sintering process take?/ How long does it take to sinter zirconia?

A2: The duration of the sintering process can vary depending on factors such as the specific zirconia material, restoration size, furnace settings, and desired properties. Generally, sintering times can range from several hours to overnight.

Q3: Can zirconia sintering furnaces be used for other ceramic materials?

A3: While zirconia sintering furnaces are primarily designed for sintering zirconia ceramics, some models may also be suitable for other ceramic materials. However, it’s important to check the furnace specifications and capabilities to ensure compatibility with the desired ceramic material.

Q4: Can zirconia sintering furnaces be used for sintering other materials besides dental restorations and jewelry components?

A4: Yes, zirconia sintering furnaces can be used for sintering zirconia ceramics in various industries beyond dental and jewelry applications. These furnaces are also used in fields such as aerospace, electronics, and biomedical engineering, where zirconia’s high strength and biocompatibility are advantageous.

Q5: How often should zirconia sintering furnaces be calibrated?

A5: Calibration frequency can vary depending on the furnace model and manufacturer’s recommendations. It’s advisable to follow the specific calibration guidelines provided in the user manual and consult the manufacturer for proper calibration intervals.

Q6: Are there any safety precautions to consider when using a zirconia sintering furnace?

A6: Yes, safety precautions should be followed when operating a zirconia sintering furnace. This includes wearing appropriate personal protective equipment, ensuring proper ventilation, and adhering to temperature limits. Familiarize yourself with the safety features of the furnace and adhere to manufacturer-recommended safety protocols.

Q7: How do I clean and maintain a zirconia sintering furnace?

A7: Cleaning and maintenance procedures can vary depending on the furnace model. It’s important to follow the manufacturer’s guidelines and instructions provided in the user manual. Regular cleaning of the furnace chamber, inspection of heating elements, and calibration of temperature sensors are common maintenance tasks.

Share this entry

You might also like