Table of Contents

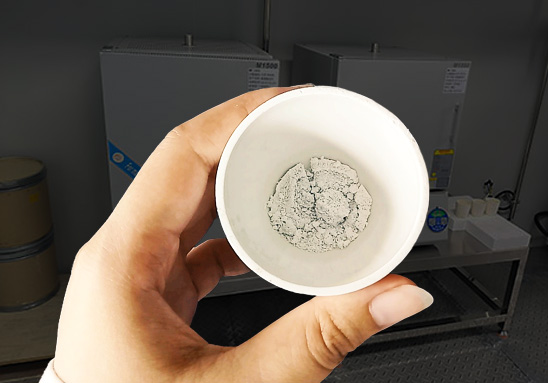

Alumina crucibles (Al₂O₃) are widely used in high-temperature applications such as ceramic sintering, metal melting, and powder heat treatment thanks to their excellent thermal stability and chemical resistance.

However, users often encounter cracking issues during use, which can lead to wasted materials, failed experiments, and production delays.

Let’s explore the common causes of crucible cracking and how to prevent them effectively.

Common Causes of Cracking

1. Thermal Shock

- What happens: Sudden cracking when heating or cooling too quickly

- Why: Alumina has low thermal conductivity and a relatively high thermal expansion rate. Rapid temperature changes create internal stresses that lead to fractures.

2. Uneven Heating

- What happens: Warping or cracking at specific areas

- Why: If the crucible is placed off-center or too close to the heat source, the temperature gradient across the body causes stress buildup.

3. Overfilling or Powder Expansion

- What happens: The walls bulge or crack outward

- Why: Some powders expand significantly during heating, generating pressure that the crucible walls can’t withstand.

4. Chemical Reaction or Gas Erosion

- What happens: Surface corrosion or brittle structure

- Why: Certain atmospheres or sample vapors may react with alumina, weakening its structure over time.

5. Microcrack Accumulation from Repeated Use

- What happens: A crucible suddenly breaks after multiple uses

- Why: Microcracks develop with each thermal cycle and eventually propagate into full fractures.

How to Prevent Crucible Cracking

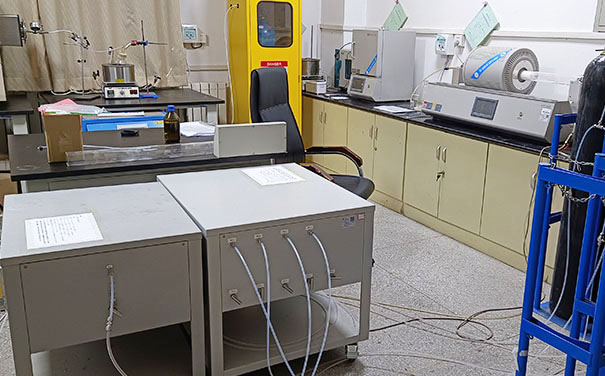

1. Control Heating & Cooling Rates

- Keep ramp rates below 5°C/min, especially between 200–600°C, where thermal stress is most severe

- Use programmable furnaces to set smooth, multi-stage temperature curves

2. Ensure Even Heating

- Place the crucible in the center of the furnace chamber

- Avoid contact with heating elements or furnace walls

- Distribute powder evenly and avoid overpacking

3. Pre-fire New Crucibles

- Preheat new crucibles at moderate temperatures for 1–2 hours before use to release internal stress

4. Choose the Right Atmosphere & Sample Loading

- Use inert gases (e.g., N₂ or Ar) when possible to avoid chemical reactions

- For reactive samples, consider using a protective liner or barrier

5. Inspect and Replace When Necessary

- Regularly check for fine cracks before reusing

- Avoid using damaged crucibles at high temperatures

ZYLAB High-Purity Alumina Crucibles

Made from ≥99.5% high-purity Al₂O₃, our crucibles offer excellent thermal shock resistance, dense structure, and long service life. Available in large-capacity, windowed, and customized designs.

Read the Article: Custom Alumina Furnace Furniture

We also provide matching furnace systems and gas control solutions to support your full sintering process.

Contact us for technical support or to request a product catalog.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!

Share this entry

You might also like