Introduction

Vacuum tube furnaces play a critical role in advanced material synthesis, enabling researchers and industry professionals to achieve precise control over temperature, atmosphere, and reaction environments. These furnaces are indispensable in fields such as nanotechnology, energy storage, and semiconductor research.

What is a Vacuum Tube Furnace?

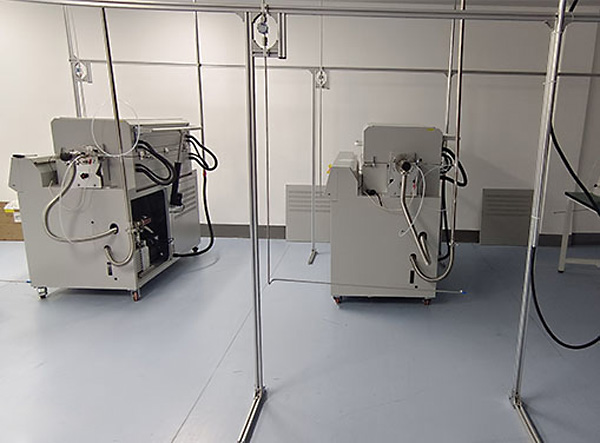

A vacuum tube furnace is a high-temperature heating device designed to operate under vacuum or controlled gas atmospheres.

It consists of a cylindrical tube enclosed within a heating element, allowing uniform thermal distribution.

The vacuum capability minimizes contamination and oxidation, making it ideal for sensitive material processing.

Key Features of Vacuum Tube Furnaces

- High-Temperature Capability: Typically ranging from 800°C to 1700°C, enabling a wide variety of synthesis processes.

- Precise Atmosphere Control: Can operate under vacuum, inert gases (e.g., argon, nitrogen), or reactive gases for tailored material properties.

- Uniform Heating: Ensures even thermal distribution, crucial for phase transformation and material crystallization.

- Gas Flow Management: Allows precise control over reactant exposure, essential for chemical vapor deposition (CVD) and gas-solid reactions.

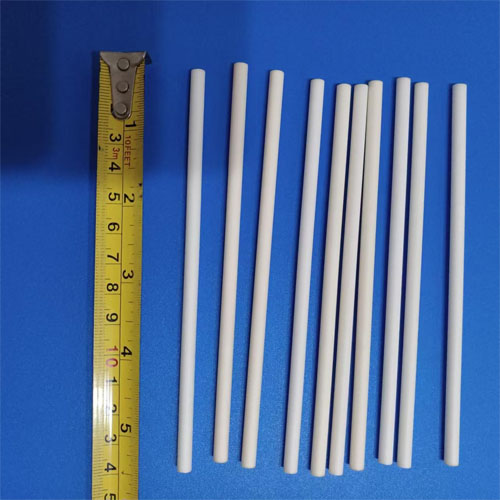

- Customization Options: Various tube materials (quartz, alumina, graphite) and configurations (single- or multi-zone heating) cater to specific research needs.

Applications in Material Synthesis

1. Nanomaterial Production

- Synthesis of carbon nanotubes (CNTs) and graphene through chemical vapor deposition (CVD).

- Growth of metal oxide nanostructures for catalysis and sensor applications.

2. Battery and Energy Storage Materials

- Development of solid-state electrolytes for next-generation lithium-ion batteries.

- Sintering of cathode and anode materials to enhance energy density and cycle stability.

3. Semiconductor and Electronic Materials

- Processing of silicon and III-V semiconductors under ultra-pure conditions.

- Fabrication of thin films and quantum dots for optoelectronic applications.

4. Metal and Alloy Research

- Reduction of metal oxides to pure metals using hydrogen atmospheres.

- Formation of high-entropy alloys with unique mechanical and thermal properties.

Conclusion

Vacuum tube furnaces are essential for cutting-edge material synthesis, offering unparalleled control over temperature and atmosphere conditions.

Whether for nanomaterial growth, semiconductor fabrication, or battery material development, these furnaces enable groundbreaking advancements in scientific research and industrial applications.

ZYLAB provides high-precision vacuum tube furnaces designed for advanced material processing. Contact us to explore our customizable solutions tailored to your research needs.