Table of Contents

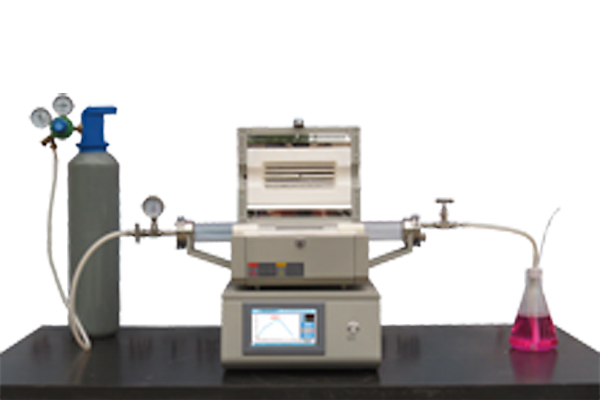

The Ultrasonic Atomization CVD Furnace has several key applications, including:

Nanomaterial Preparation:

Suitable for synthesizing a wide range of nanomaterials, including nanoparticles, nanowires, and thin films, by facilitating controlled deposition using non-volatile precursors.

lectrode Material Coating:

Used for coating and composite materials, especially in applications like batteries, supercapacitors, and fuel cells, where uniform and thin coatings of electrode materials are essential.

Transparent Conductive Films:

Ideal for the growth of transparent conductive oxide (TCO) films, such as ZnO, which are used in optoelectronic devices like displays, touchscreens, and solar cells.

Catalyst Development:

Supports the fabrication and coating of catalysts, which are essential for chemical reactions in processes like catalysis, environmental remediation, and fuel cell development.

Sensor Fabrication:

Useful in producing thin films and nanostructures for sensors, including gas sensors, biosensors, and other chemical sensors, due to the precise control over material composition and structure.

Advanced Coating Technologies:

Enables advanced coating processes for various materials, including metals, ceramics, and polymers, enhancing their surface properties such as corrosion resistance, hardness, and wear resistance.

Research and Development:

Widely used in R&D environments for developing new materials, optimizing coating processes, and studying the properties of materials at high temperatures or under specific conditions.

These applications leverage the ability of the equipment to operate with non-volatile precursors, provide precise control over deposition parameters, and achieve uniform thin films and coatings.