Table of Contents

A tube furnace is a versatile piece of scientific equipment widely used in research, industrial processes, and educational laboratories. One of its defining features is its ability to achieve precise temperature control across a wide range.

Understanding the temperature capabilities of a tube furnace is crucial for selecting the right equipment for your specific application.

Temperature Ranges of Tube Furnaces

Tube furnaces can generally be categorized based on their maximum temperature capabilities:

Low-Temperature Tube Furnaces (<800°C):

- Used for processes such as drying, low-temperature polymer studies, or basic thermal treatments.

- Commonly found in entry-level laboratories or educational institutions.

Medium-Temperature Tube Furnaces (800°C–1200°C):

- Ideal for annealing, catalyst research, and moderate thermal processing.

- Frequently equipped with quartz or stainless steel tubes.

High-Temperature Tube Furnaces (1200°C–1700°C):

- Designed for advanced materials synthesis, ceramics sintering, and other high-temperature applications.

- Often feature alumina or silicon carbide heating elements for superior performance.

Ultra-High-Temperature Tube Furnaces (>1700°C):

- Suitable for specialized applications such as refractory material testing, crystal growth, and advanced metallurgy.

- Typically use graphite or molybdenum disilicide heating elements.

Key Factors Influencing Tube Furnace Temperature

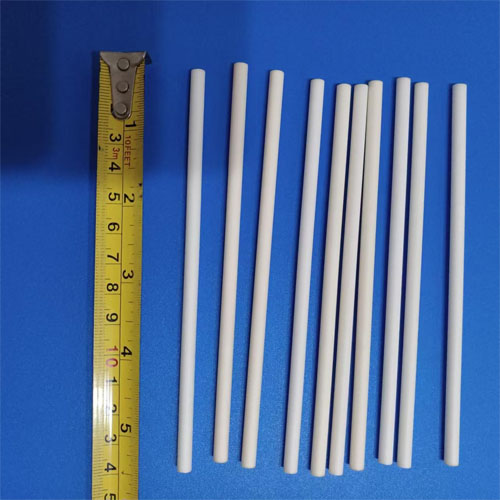

1. Material of the Furnace Tube:

- Quartz: Suitable for low to medium temperatures, up to 1200°C. Resistant to thermal shock and ideal for clean environments.

- Alumina (Al2O3): Withstands higher temperatures up to 1700°C. Commonly used for high-temperature experiments.

- Stainless Steel: Durable and corrosion-resistant, typically limited to 1200°C, depending on the specific alloy.

2. Heating Elements:

- Iron-Chromium-Aluminum (FeCrAl) Wire: Common in medium-temperature furnaces.

- Silicon Carbide (SiC): Provides excellent performance in high-temperature applications.

- Molybdenum Disilicide (MoSi2): Operates efficiently at ultra-high temperatures.

3. Insulation Materials:

Insulation quality directly affects the furnace’s temperature stability and energy efficiency. High-grade ceramic fibers are often used for optimal thermal retention.

4. Temperature Control Systems:

Modern tube furnaces incorporate advanced PID (Proportional-Integral-Derivative) controllers and programmable logic controllers (PLCs) for precise temperature management.

Applications of Tube Furnaces Across Temperature Ranges

Medium-Temperature Applications (800°C–1200°C):

- Catalyst Development: Studying reactions under controlled atmospheres.

- Material Testing: Evaluating mechanical and thermal properties of metals and ceramics.

- Gas Phase Reactions: Conducting experiments in oxidation, reduction, and pyrolysis.

High-Temperature Applications (1200°C–1700°C):

- Ceramics Sintering: Producing high-strength, high-density ceramic components.

- Powder Metallurgy: Compacting and sintering metal powders for industrial use.

- Crystal Growth: Synthesizing advanced crystals for semiconductors and optics.

Why Choose ZYLAB Tube Furnaces?

At ZYLAB, we offer a range of tube furnaces tailored to meet diverse temperature requirements:

- Customizable Designs: Choose from various tube materials, heating elements, and insulation options.

- High-Temperature Precision: Ensure stable and uniform temperature distribution with advanced controllers.

- Safety Features: Multiple layers of protection, including gas safety systems and over-temperature alarms.

- Ease of Use: Intuitive touchscreen interfaces and pre-programmed heating profiles for effortless operation.

Whether medium-temperature or high-temperature, ZYLAB’s products are characterized by high quality, intelligence, and safety, providing ideal solutions for research and industrial applications.

Conclusion

The temperature of a tube furnace varies depending on its design, materials, and intended application. From low-temperature research to ultra-high-temperature industrial processes, these furnaces play a pivotal role in advancing technology and innovation. Selecting the right temperature range and features is essential to achieving optimal results for your specific needs.

Contact ZYLAB today to explore our comprehensive range of tube furnaces and find the perfect solution for your application!