Table of Contents

Introduction

In the field of advanced materials research, precise temperature control and uniform heating are crucial for achieving optimal experimental results.

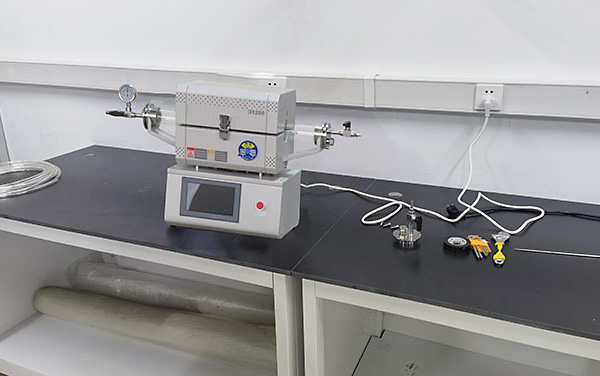

The 1200°C Mini Tube Furnace is an essential laboratory tool designed for high-temperature experiments, including sample sintering, heat treatment, and thermal decomposition.

This compact yet powerful furnace is widely used in new material synthesis and characterization, making it indispensable for research institutions and industrial laboratories.

Key Applications of the 1200°C Mini Tube Furnace

1. Sintering of Advanced Materials

Sintering is a critical step in material processing, where powders are subjected to high temperatures to form dense, solid structures. The 1200°C Mini Tube Furnace provides a controlled environment for the sintering of materials such as:

- Ceramics and oxide materials

- Metal and alloy powders

- Nanostructured materials

- Battery electrode materials

2. Heat Treatment and Thermal Annealing

The precise temperature control of the mini tube furnace allows researchers to fine-tune material properties through heat treatment processes, including:

- Crystallization of amorphous materials

- Phase transitions in semiconductor materials

- Stress relief and grain growth control in metals

3. Thermal Decomposition and Gas-Solid Reactions

Many advanced materials require gas-assisted synthesis or controlled-atmosphere heat treatments. The mini tube furnace enables experiments under various atmospheres, such as argon, nitrogen, or hydrogen, to facilitate:

- Carbonization and pyrolysis of polymer precursors

- Synthesis of porous materials like MOFs and zeolites

- Reduction reactions for metal oxide processing

Advantages of the 1200°C Mini Tube Furnace

1. Precise Temperature Control

Equipped with an advanced PID controller, the furnace ensures accurate temperature regulation, reducing fluctuations and ensuring repeatable experimental conditions.

2. Compact Design with High Efficiency

Unlike large industrial furnaces, the mini tube furnace is designed to maximize efficiency while minimizing space requirements, making it ideal for laboratory-scale research.

3. Compatibility with Different Gas Environments

The ability to introduce various gases through gas flow controllers and sealed tube ends enhances its versatility for atmosphere-sensitive experiments.

Why Choose a 1200°C Mini Tube Furnace for New Material Research?

As the demand for next-generation materials continues to grow, having a reliable high-temperature furnace is essential for researchers and engineers. The 1200°C Mini Tube Furnace is an ideal choice due to its:

- High precision and repeatability

- Versatility across multiple research applications

- Compact yet powerful heating capabilities

- Ability to perform experiments under various controlled environments

Conclusion

For researchers focused on material synthesis, sintering, and thermal treatment, the 1200°C Mini Tube Furnace is a must-have laboratory instrument. Its precise temperature control, flexible atmosphere compatibility, and efficient heating make it an invaluable tool for advancing new materials research.

If you’re looking for a high-performance mini tube furnace, contact ZYLAB today. Our team is ready to provide customized solutions to meet your experimental needs.

Click here to learn more about ZYLAB tube furnaces.