Tube furnaces are widely used in materials science due to their ability to deliver precise, high-temperature environments under controlled atmospheres. They play a critical role in research and development across various fields such as metallurgy, ceramics, crystal growth, and nanomaterials.

Tag Archives: Tube Furnace Applications

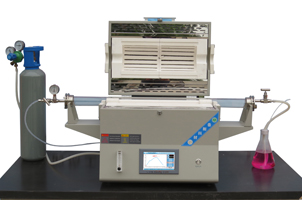

A tube furnace is a type of high-temperature electric furnace commonly used in laboratories and industries, primarily for various applications such as material synthesis, heat treatment, and atmosphere control experiments. Its basic structure includes a heating element, a hollow tubular chamber (usually made of quartz or ceramic), and a temperature control system. The tube furnace generates a high-temperature environment inside the tube for heating treatment.

Tubular furnaces are versatile tools for high-temperature applications, materials processing, and various research processes.

It features three independently controlled heating zones within a single tube, making it suitable for applications that require specific thermal profiles or temperature gradients. These furnaces are widely used in materials processing, research, and industrial applications.

A mini tube furnace is a compact and versatile high-temperature heating device commonly used in laboratories and small-scale industrial settings.

A laboratory tube furnace is comprises a tubular chamber where samples or materials are heated to high temperatures for processes such as annealing, sintering, chemical reactions, and materials research.

A tube furnace is a type of high-temperature heating device used in various laboratory and industrial applications.The furnace is designed to heat materials to elevated temperatures in a controlled environment.

.jpg)