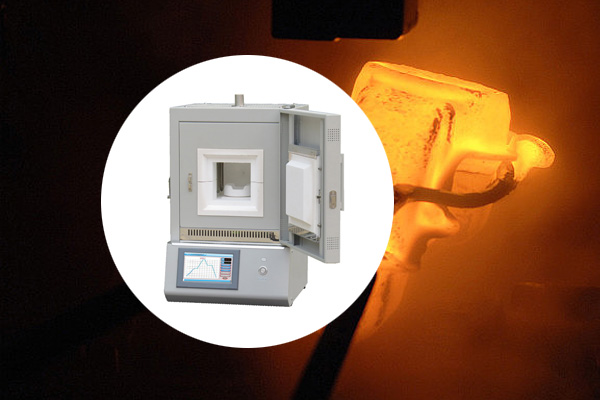

Muffle furnaces are essential tools in modern materials research, especially for ceramic and metal sintering applications. In research and development (R&D) laboratories, where precision, repeatability, and control are paramount, muffle furnaces provide the reliable thermal environment necessary for studying advanced materials and developing new processes.

Tag Archives: Sintering Furnace

Both muffle furnaces and tube furnaces serve essential roles in high-temperature applications, but choosing the right one depends on your specific needs. If you require a chamber-style furnace for bulk materials, a Muffle Furnace is the best choice. However, if you need controlled atmospheres and precise gas flow for your experiments, a Tube Furnace is more suitable.

The significance of sintering extends across a myriad of industries, including automotive, electronics, aerospace, medical, ceramics, and powder metallurgy. By enabling the fabrication of complex geometries, high-performance components, and customized materials, sintering furnaces play a pivotal role in advancing product design, functionality, and efficiency across diverse sectors.

Crucible furnaces are versatile and can accommodate a wide range of materials, making them useful in various fields including metallurgy, ceramics, glass manufacturing, and materials science research.

Hot press furnaces find applications in various industries and materials processing techniques due to their ability to provide controlled high-temperature and pressure conditions.

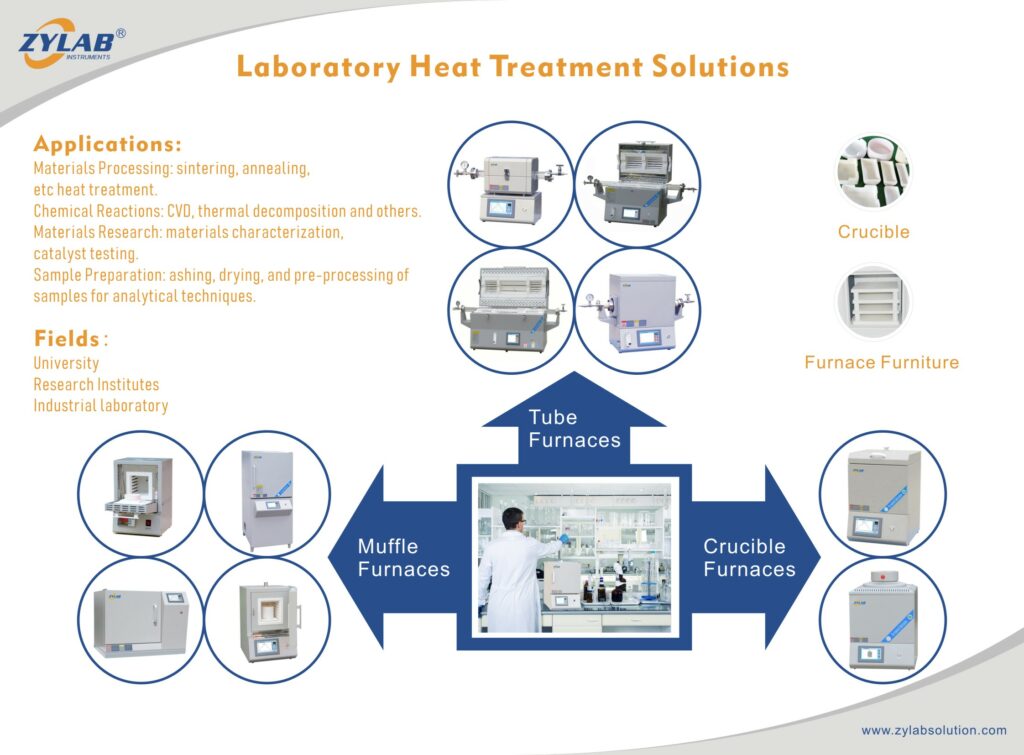

Applications:

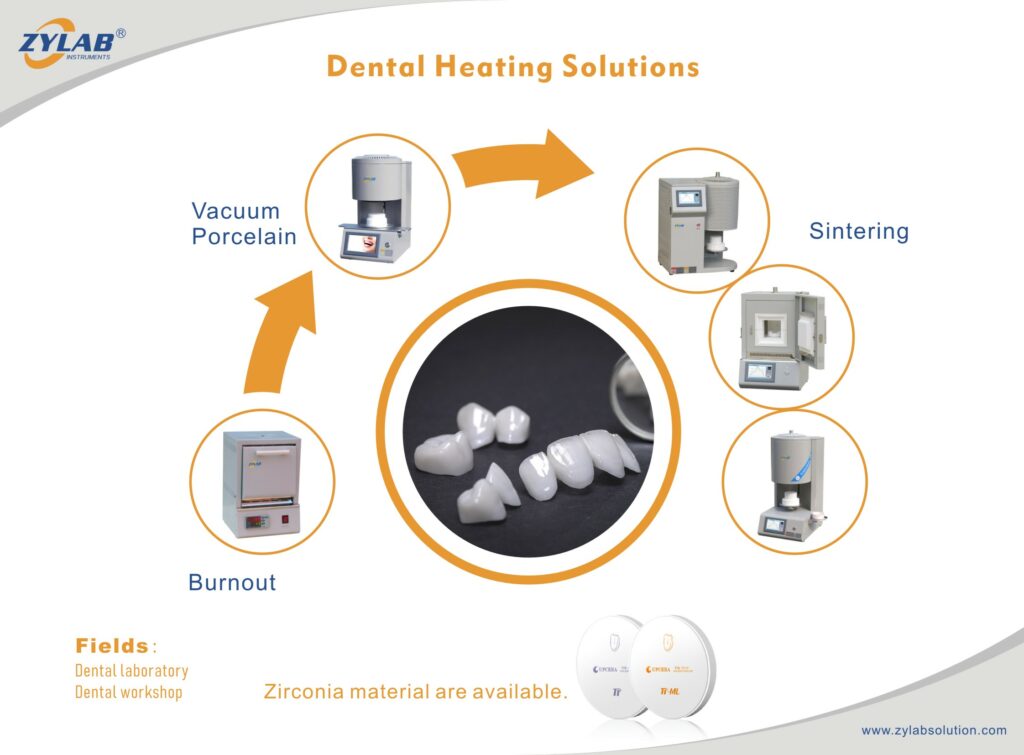

Burnout

Vacuum Porcelain

Sintering

Materials Processing: sintering, annealing, etc heat treatment.

Chemical Reactions: CVD, thermal decomposition and others.

Materials Research: materials characterization,catalyst testing.

Sample Preparation: ashing, drying, and pre-processing of samples for analytical techniques.

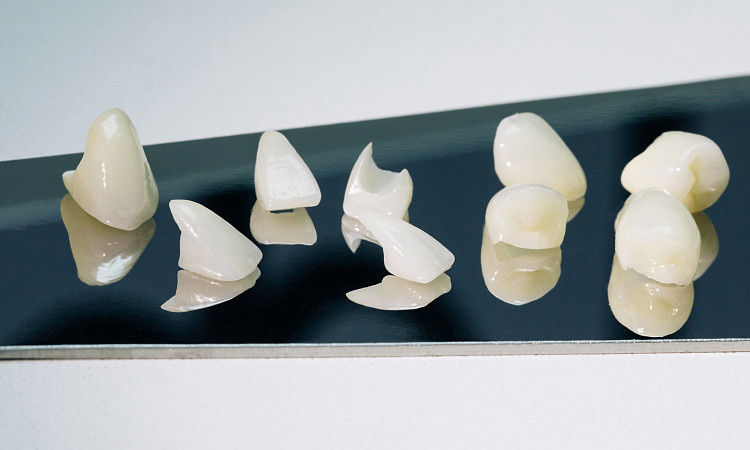

In dental applications, sintering furnaces are primarily used for the production of ceramic dental restorations, including crowns, bridges, and implant abutments.

A dental ceramic furnace, also known as a dental porcelain furnace or dental firing furnace, is a specialized piece of equipment used in the dental industry for the firing or crystallization of dental ceramic materials.

A zirconia sintering furnace is a specialized piece of equipment used in the dental and jewelry industries for the sintering or firing of zirconia ceramic materials.

- 1

- 2