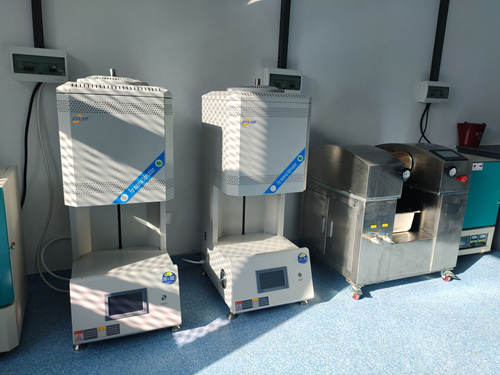

Choosing the right sintering equipment is key to ensuring uniform heating, safe handling, and high precision for these large-scale components. In this guide, we explore why a bottom-loading sintering furnace is the ideal choice for large workpiece sintering applications.

Tag Archives: High-temperature sintering furnace

This specialized furnace enables controlled sintering, chemical reactions, and phase transformations under extreme conditions, offering significant advantages in material development, energy applications, and fundamental scientific research.

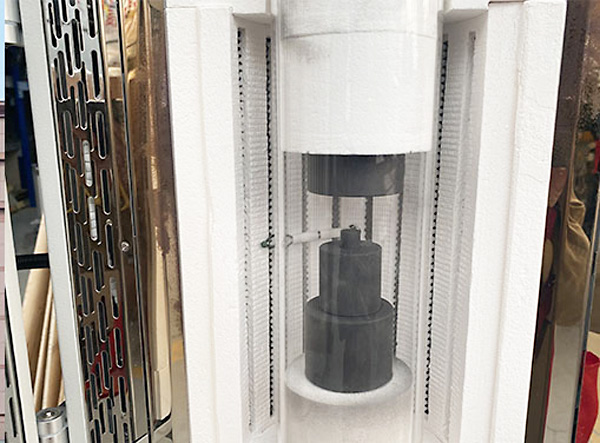

The 1200°C Vacuum Hot Press Furnace is a powerful tool for both metal powder densification and ceramic material sintering. Its ability to operate under high pressure and in a controlled vacuum environment allows for precise material treatment, leading to enhanced material properties and reduced defects.

When using a 1700°C high-temperature sintering furnace, it is essential to follow specific precautions to ensure safe and efficient operation.

The significance of sintering extends across a myriad of industries, including automotive, electronics, aerospace, medical, ceramics, and powder metallurgy. By enabling the fabrication of complex geometries, high-performance components, and customized materials, sintering furnaces play a pivotal role in advancing product design, functionality, and efficiency across diverse sectors.

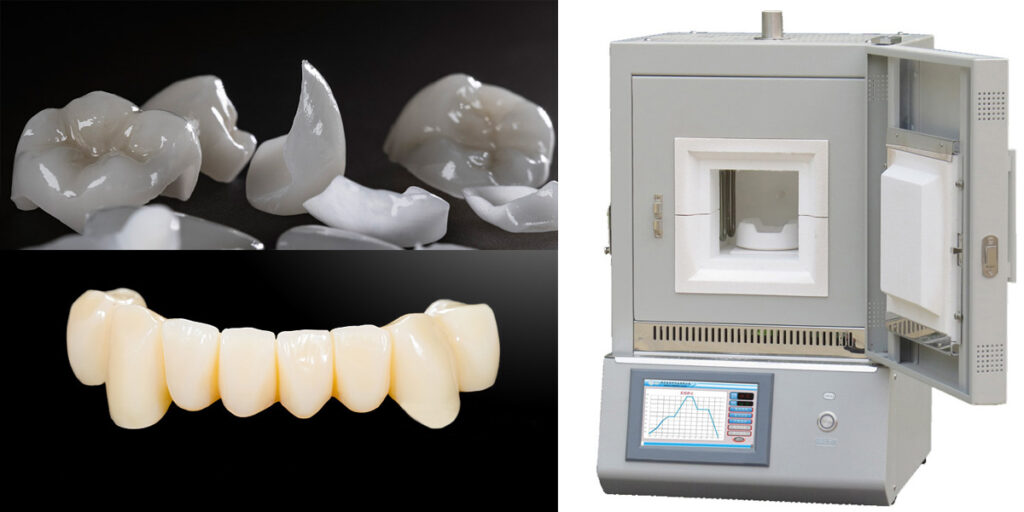

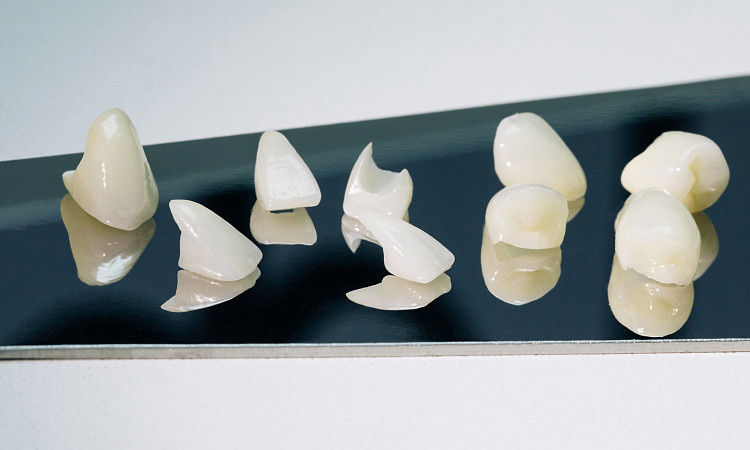

In dental applications, sintering furnaces are primarily used for the production of ceramic dental restorations, including crowns, bridges, and implant abutments.