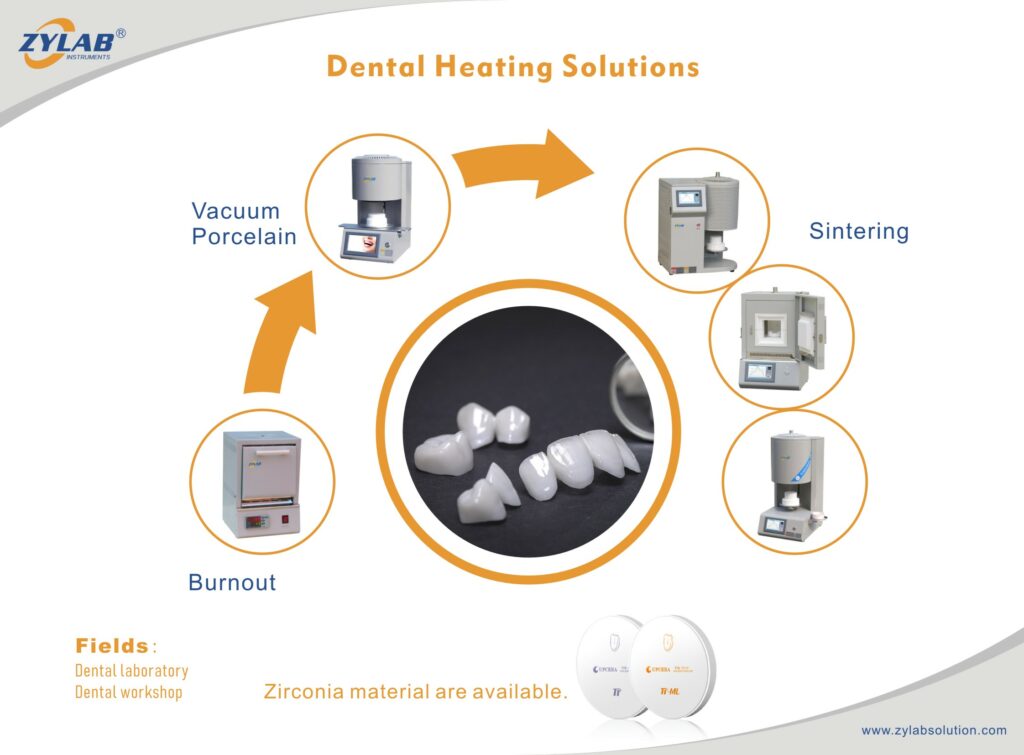

Applications:

Burnout

Vacuum Porcelain

Sintering

Tag Archives: Dental Furnace

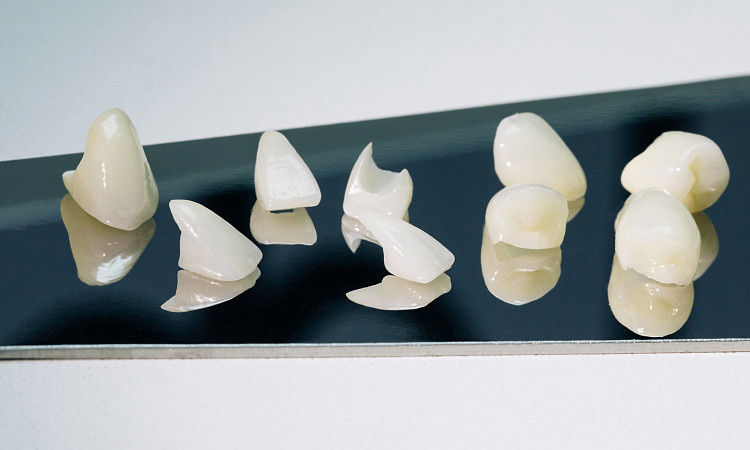

Porcelain furnaces are primarily used in the process of dental ceramic firing, which involves the application of heat to dental ceramic materials to achieve their desired properties. Dental ceramics, such as porcelain, are commonly used in the fabrication of dental crowns, veneers, bridges, and other restorative and cosmetic dental prosthetics.

In dental applications, sintering furnaces are primarily used for the production of ceramic dental restorations, including crowns, bridges, and implant abutments.

A dental ceramic furnace, also known as a dental porcelain furnace or dental firing furnace, is a specialized piece of equipment used in the dental industry for the firing or crystallization of dental ceramic materials.

Burnout furnaces are essential tools in the dental and jewelry industries, enabling the production of high-quality castings with precise details and accurate fit. Their ability to efficiently eliminate wax patterns or organic materials from investment molds is crucial for achieving successful casting results.

A zirconia sintering furnace is a specialized piece of equipment used in the dental and jewelry industries for the sintering or firing of zirconia ceramic materials.

Our technical support team is always ready to assist with any technical issues, and our after-sales services ensure that our customers’ electric furnaces operate at peak performance and longevity.

ZYLAB Furnaces, come with low power consumable, exquisite structure and light weight, are the ideal electric furnaces for material research labs, scientific research and various institutes, also widely used in the dental field for burnout, sintering.

Choosing the right supplier of laboratory electric furnace solutions is essential for the success of your research projects.

To ensure that the electric furnaces function efficiently and have a longer lifespan, proper maintenance and upkeep are essential.

- 1

- 2