When it comes to working at temperatures above 1000°C, what’s happening around your material can be just as important as what’s happening to it. That’s where atmosphere control comes in — a silent, invisible force that shapes everything from material quality to process safety.

Tag Archives: CVD Furnace

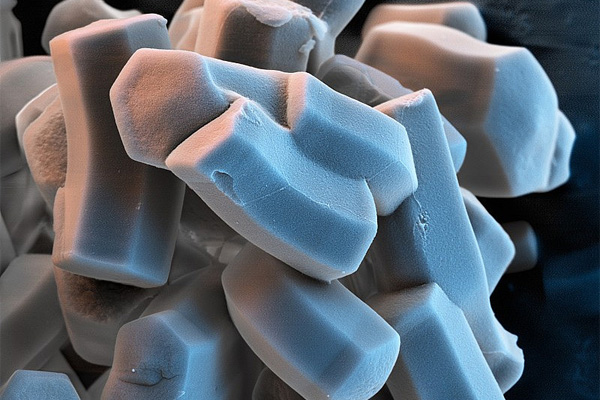

Porous materials are widely used in catalysis, gas storage, separation technologies, and energy storage due to their high surface area, tunable pore structures, and excellent chemical stability. Among them, Metal-Organic Frameworks (MOFs) and silica (SiO₂) are two of the most prominent representatives. Thermal treatment plays a crucial role in optimizing their structural and functional properties.

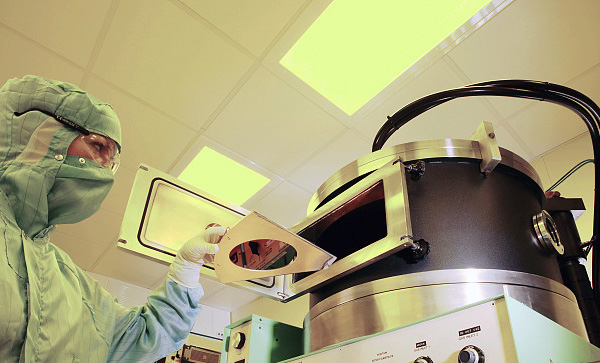

Chemical Vapor Deposition (CVD) technology is widely used in semiconductor manufacturing, optics, thin-film coatings, and material science. Within this technology, different types of CVD furnaces exist, including CVD, PECVD (Plasma-Enhanced CVD), and FBCVD (Fluidized Bed CVD).