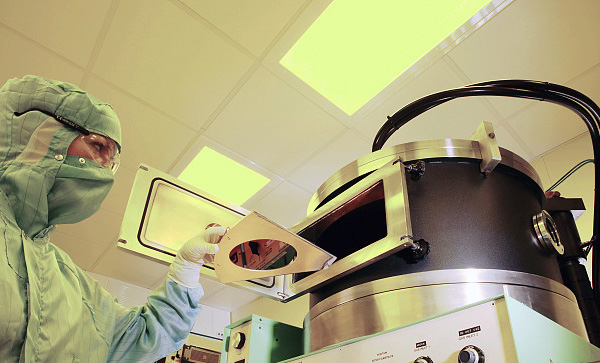

Achieving high-quality SiC coatings requires advanced deposition technologies, and among them, High Vacuum Chemical Vapor Deposition (CVD) Furnaces stand out as a preferred solution. In this article, we explore how high vacuum CVD furnaces are used for SiC coating preparation and why they are crucial in modern material science.

Tag Archives: Chemical Vapor Deposition Furnace

CVD (Chemical Vapor Deposition) tube furnace sintering systems play a crucial role in achieving high-quality 2D material growth and structural refinement. In this blog, we explore the applications of CVD tube furnace sintering systems in 2D material synthesis and processing.

Chemical Vapor Deposition (CVD) technology is widely used in semiconductor manufacturing, optics, thin-film coatings, and material science. Within this technology, different types of CVD furnaces exist, including CVD, PECVD (Plasma-Enhanced CVD), and FBCVD (Fluidized Bed CVD).

A CVD furnace (Chemical Vapor Deposition furnace) is a specialized high-temperature system designed to deposit thin films or coatings onto substrates through chemical vapor deposition.

A CVD (Chemical Vapor Deposition) furnace system is a type of equipment used for the deposition of thin films or coatings onto substrates through chemical reactions at elevated temperatures. It typically consists of various components designed to control the deposition process and ensure the growth of high-quality films.