Table of Contents

What is a Rotary Tube Furnace and Its Applications?

A rotary tube furnace is a specialized piece of equipment used for various high-temperature processes where the furnace tube rotates to ensure uniform heat distribution. This rotation allows materials inside the furnace to experience consistent temperature exposure, which is essential for achieving the desired material properties.

Applications of rotary tube furnaces are vast, particularly in industries that require controlled heating and treatment of materials in powder or granular form. Some common applications include:

- Material Synthesis: Used for the preparation of advanced materials, including nanomaterials and composites.

- Heat Treatment: Crucial for the sintering, calcination, and heat treatment of metals, ceramics, and alloys.

- Powder Metallurgy: Essential for processing powdered materials for powder metallurgy applications.

- Catalyst Production: Utilized in the production of catalytic materials for chemical reactions.

- Nanomaterial Synthesis: Facilitates the creation of nano-scale materials for a wide range of high-tech applications.

Rotary tube furnaces are indispensable in these sectors due to their ability to handle high temperatures, uniform material processing, and adaptability to different atmospheres or vacuum conditions.

Key Factors Influencing Rotary Tube Furnace Prices

Several factors contribute to the overall price of a rotary tube furnace, which can vary widely based on technical specifications and customization:

- Temperature Range: High-performance rotary tube furnaces capable of reaching temperatures up to 1200°C or higher tend to be more expensive. Furnaces designed for extreme high-temperature applications will include more advanced materials and design features, increasing costs.

- Size and Specifications: The furnace’s size—such as the diameter and length of the furnace tube, as well as its capacity—plays a major role in pricing. Larger furnaces with greater processing volumes typically incur higher costs.

- Control Systems: Furnaces equipped with advanced automated control systems, PLC interfaces, or WiFi connectivity for remote monitoring often come at a premium. These systems ensure precise temperature regulation and ease of use, making them particularly valuable in complex applications.

- Special Features: Features like vacuum operation, atmosphere mixing, automatic feeding and discharge, and sealing mechanisms that enable controlled environments contribute to higher prices due to the complexity and added components.

- Material and Construction: High-quality insulation materials like high-purity alumina fiber and the use of stainless steel alloys for furnace tubes (such as 310S or 316L) significantly affect pricing. The durability and heat resistance of these materials justify their cost in providing long-lasting performance.

- Brand and After-Sales Support: Renowned brands, such as ZYLAB, often offer superior technical support and extended warranties. While these brands might be priced higher initially, the added customer service and reliability can prove valuable over time.

Considerations When Choosing a Rotary Tube Furnace

When selecting a rotary tube furnace, it’s essential to consider the following:

- Application Needs: Understand whether your application requires basic sintering or more complex processes, such as material synthesis or high-temperature testing under specific atmospheric conditions.

- Cost-Effectiveness: While it’s tempting to focus solely on the initial cost, consider the long-term operational costs, such as energy consumption and the ease of maintenance. Energy-efficient designs can save substantial costs over the life of the furnace.

- Maintenance and Support: Evaluate the furnace’s ease of maintenance. Features like modular design, easy access to components, and reliable after-sales support can reduce downtime and maintenance costs.

Market Price Range and Trends

The price of rotary tube furnaces varies depending on performance levels and customization:

- Entry-Level Furnaces: These furnaces, typically with simpler features and lower temperature ranges (e.g., up to 1000°C), can start at around $5,000 to $15,000.

- Mid-Range Furnaces: With enhanced features like advanced temperature control, automation, and better materials, the price range can be from $20,000 to $40,000.

- High-End Furnaces: Furnaces designed for extreme conditions or specialized applications (e.g., high-temperature capabilities, vacuum systems, automated feeding) can cost anywhere from $50,000 to $100,000 or more.

The price trends are influenced by advancements in technology, such as improved insulation materials and enhanced control systems, making energy-efficient designs increasingly popular.

Additionally, environmental regulations and market demands for cleaner processes are prompting manufacturers to incorporate more sustainable features, potentially affecting costs.

Advantages of ZYLAB’s Rotary Tube Furnace

ZYLAB’s rotary tube furnaces are designed with precision and reliability in mind, offering the following advantages:

- High Precision Temperature Control: ZYLAB furnaces feature advanced PID control systems, ensuring temperature stability within ±1°C, making them ideal for sensitive processes.

- Customization Options: ZYLAB offers a range of customizable features, including the ability to configure for different temperature zones, atmosphere mixing, and vacuum conditions.

- Energy Efficiency: ZYLAB furnaces are equipped with high-quality insulation and efficient heating elements to reduce energy consumption and operating costs.

- Proven Industry Success: ZYLAB’s furnaces are used in a variety of industries, from nanomaterial production to powder metallurgy, offering consistent, reliable performance across diverse applications.

- Competitive Pricing and After-Sales Service: While ZYLAB provides high-quality, customizable furnaces, the price remains competitive. Additionally, the company offers excellent after-sales support, including training, warranties, and maintenance services, ensuring long-term satisfaction.

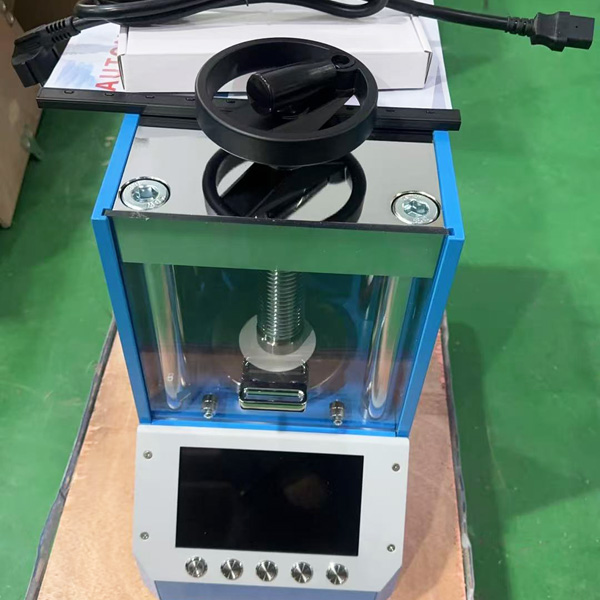

Rotary Tube Furnace Image

Why Choose ZYLAB’s Rotary Tube Furnace?

Investing in a rotary tube furnace can significantly enhance your production capabilities and process efficiency. Whether you’re involved in materials research, catalyst production, or sintering processes, selecting the right furnace is crucial to achieving consistent results.

ZYLAB’s rotary tube furnaces provide the perfect blend of advanced features, customizability, and energy efficiency at competitive prices. With superior control, durability, and after-sales support, ZYLAB ensures that your investment delivers long-term value.

For a detailed quote or to explore customized solutions tailored to your needs, feel free to contact ZYLAB. Let us help you optimize your processes with the best rotary tube furnace for your application.

Contact us today to get a personalized quote for your rotary tube furnace needs!

Share this entry

You might also like