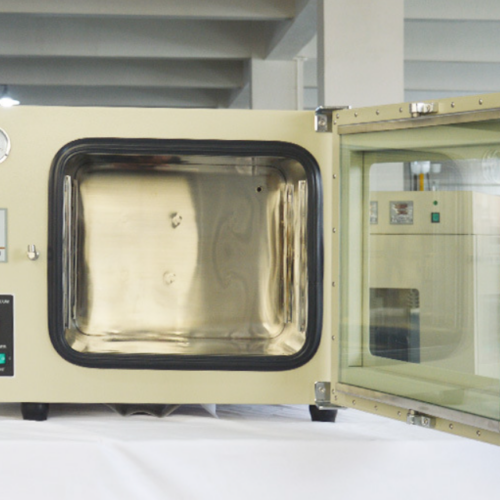

Big Capacity Vertical Vacuum Drying Oven

Introduction:

Vertical Vacuum Drying Oven is a type of laboratory oven, used to remove moisture or other volatile substances from samples in a low-pressure environment.

The oven works by creating a vacuum inside the chamber, which reduces the boiling point of liquids, allowing them to evaporate more easily. This makes it a useful tool for drying heat-sensitive materials, such as powders, crystals, and biological samples, without causing damage.

Highlight:

1. The liner is made of 2mm thick stainless steel, and several reinforcing ribs are firmly welded to ensure that the liner is not deformed.

2. Intelligent controller, high temperature control accuracy, fast temperature stabilization time. Multi-steps programmable controller(optional).

3. Double glass, visual observation window. External PE transparent plate, internal 12mm explosion-proof tempered glass.

4. The back of the oven is equipped with an inflation interface, which can inflate inert gas into the box. Stainless steel interface with valve.

Detail Characteristics:

1.Radiant warm wall heating system provides optimal uniformity and conserves chamber space for drying, curing, vacuum embedding, and plating applications.

2. 3″ (7.6 cm) glass wool insulation prevents heat loss from working chamber, and minimizes the enclosure’s outer surface temperature.

3. Silicone door gasket and positive latch door maintain seal at all vacuum levels.

4. PID precision Digital Power controller controls temperature with a accuracy of +/-1°C and built-in over temperature protection.

5. Easy-to-clean #304 stainless steel chamber interior, durability and ease of maintenance.

6. 2 or 3 shelves were included for immediate use.

7.Vacuum and air lines constructed with corrosion-resistant stainless steel tubing for optimum chamber cleanliness and long term performance.

8.Celsius(.C) and Fahrenheit (.F)can be switched at will.

9.Operating temperature range from room temperature to 250°C Max.(RT ~ 200°C for continuous;200°C ~ 250°C for <4hrs).

Technical Parameters:

| Model | ZYLAB-6210 | ZYLAB-6090 | ZYLAB-6050 | ZYLAB-6020 |

| Power supply | 220V 50HZ | |||

| Rated power | 2000W | 1500W | 1500W | 1200W |

| Temp range | 50-250.C | |||

| Temp accuracy | ± 1.C | |||

| Vacuum Level | <133Pa | |||

| Chamber

size (mm) |

560*600*640 | 450*450*450 | 415*370*345 | 300*300*275 |

| Outer Dimension(mm) | 720*735*1500 | 610*585*1210 | 710*510*516 | 595*440*446 |

| Shelves | 3 pcs

(Independent temp control) |

2 pcs

(Independent temp control) |

2 pcs | 2 pcs |

Which Kinds of Industry Use This Vertical Vacuum Drying Oven?

Vacuum drying ovens are used in a variety of industries that require a controlled environment for drying, heating, or curing processes. Some of the industries that use ZYLAB vacuum drying ovens include:

- Materials Science and Engineering: To dry and heat-treat samples of various materials, including metals, ceramics, and polymers.

- Pharmaceutical and Biotech: In the pharmaceutical and biotech industries for drying and sterilizing equipment, instruments, and other items.

- Electronics: In the electronics industry for drying and curing electronic components and materials.

- Aerospace: In the aerospace industry for curing and drying composite materials used in aircraft manufacturing.

- Food and Beverage: In the food and beverage industry for drying and processing food products such as herbs, spices, and fruits.

- Automotive: In the automotive industry for curing and drying composite materials used in automotive manufacturing.

- Research and Development: In research and development laboratories for a wide range of applications, including material synthesis, polymerization, and processing.

Detail Applications of Vertical Vacuum Drying Oven:

Vacuum drying ovens are versatile equipment commonly used in various applications that require precise temperature control and low-pressure environments. Here are some detailed applications of ZYLAB vacuum drying ovens:

Drying: For low-temperature drying of various materials such as powders, crystals, and biological samples. The low-pressure environment in the oven helps to reduce the boiling point of the solvent, allowing for faster and more efficient drying.

Sterilization: For sterilization of laboratory equipment, labware, and various pharmaceutical products. The low-pressure environment and high temperature help to kill microorganisms and bacteria that may contaminate the products.

Curing: For curing materials such as composites, adhesives, and coatings used in various industries such as aerospace, automotive, and electronics. The low-pressure environment and precise temperature control help to improve the quality and durability of the cured materials.

Heat treatment: For heat treatment of various materials such as metals, ceramics, and polymers. The low-pressure environment helps to reduce oxidation and contamination, while the precise temperature control allows for uniform heating of the materials.

Aging: For aging of various materials such as rubber, plastics, and other organic materials. The low-pressure environment and controlled temperature and humidity help to simulate the aging process and evaluate the durability and performance of the materials.

Food preservation: For low-temperature drying and preservation of food products such as fruits, vegetables, and meats. The low-pressure environment helps to reduce the boiling point of the water, allowing for faster and more efficient drying, while preserving the nutrients and flavors of the food.