Laboratory Small Vertical Tube Furnace 1200℃

Introduction:

The vertical tube furnace 1200.C features a design where the furnace tube is vertically placed and heating elements are distributed in a circular arrangement. It is suitable for small steel parts quenching, annealing, tempering heat treatment, and vertical CVD coating. The equipment can operate under atmospheric or vacuum conditions, and can also be used as a standard tube furnace, making it ideal for university laboratories and research institutes.

Features and Benefits:

- Uniform Temperature Distribution: The heating elements are circularly distributed around the furnace chamber, encircling the tube 360 degrees, which enhances temperature uniformity within the chamber.

- High-Purity Al2O3 Insulation: The furnace uses high-purity alumina fiber insulation material, providing excellent thermal insulation and effectively reducing energy consumption.

- Dual-Layer Air-Cooled Structure: The furnace body is designed with a dual-layer air-cooling structure, which helps reduce the surface temperature of the outer casing.

- Intelligent PID Control: The furnace features intelligent PID fuzzy temperature control and a 7-inch touchscreen for centralized operation, with an intuitive display of the “time-temperature” curve.

- Integrated Water-Cooled Flange: The use of an integrated water-cooled flange prevents overheating and damage to the sealing ring, ensuring optimal sealing of the equipment.

Technical Parameters of Vertical Tube Furnace 1200℃:

| Model | LTO1200-60TI-150

|

||||||

| Power Supply | AC220V 2KW | ||||||

| Max.temp | 1200℃(<1 hour) | ||||||

| Long-Term Operating Temperature Range | 300~1150℃ | ||||||

| Constant Temperature Zone | 100mm | ||||||

| Heating Rate | 1℃/H-20℃/Min | ||||||

| Heating Zone Length | 200mm | ||||||

| Quartz Tube Size | Φ60*700mm | ||||||

| Dimensions | L760*H1400*D520mm

|

||||||

| Control System | 1.Sintering process curve setting: Dynamic display of the set curve, with multiple sintering process curves pre-stored, and each curve can be freely set.

2.Sintering scheduling: Allows for unattended sintering based on preset sintering process curves. 3.Real-time display of sintering power, voltage, and other data, with data logging and export capabilities for paperless records. 4.Remote operation capability for real-time monitoring of equipment status. 5.Temperature correction: Non-linear correction throughout the sintering process for the difference between the control temperature and sample temperature.

|

||||||

| Heating Element |

Mo-doped Fe-Cr-Al alloy |

||||||

| Temperature Accuracy | +/- 1 ℃ | ||||||

| Sealing System |  |

|

|||||

| Vacuum Level: ≤10Pa (mechanical pump) | |||||||

| Pressure Measurement & Monitoring | Utilizes a mechanical pressure gauge with a gas-tight enclosure to effectively protect internal components from environmental influences and debris, with strong corrosion and high-temperature resistance.

|

||||||

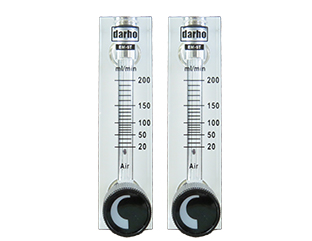

| Gas Supply System |

The gas flow rate is controlled by a rotameter, integrated with the equipment, and has undergone leak testing prior to shipment. |

||||||

| Service Support | 1-year warranty with lifetime support (excluding consumable parts such as furnace tubes and sealing rings). | ||||||

Applications:

The Vertical Tube Furnace 1200℃ is suitable for small steel parts quenching, annealing, tempering heat treatment, and vertical CVD coating, etc. The equipment can operate under atmospheric or vacuum conditions, and can also be used as a standard tube furnace, making it ideal for university laboratories and research institutes.