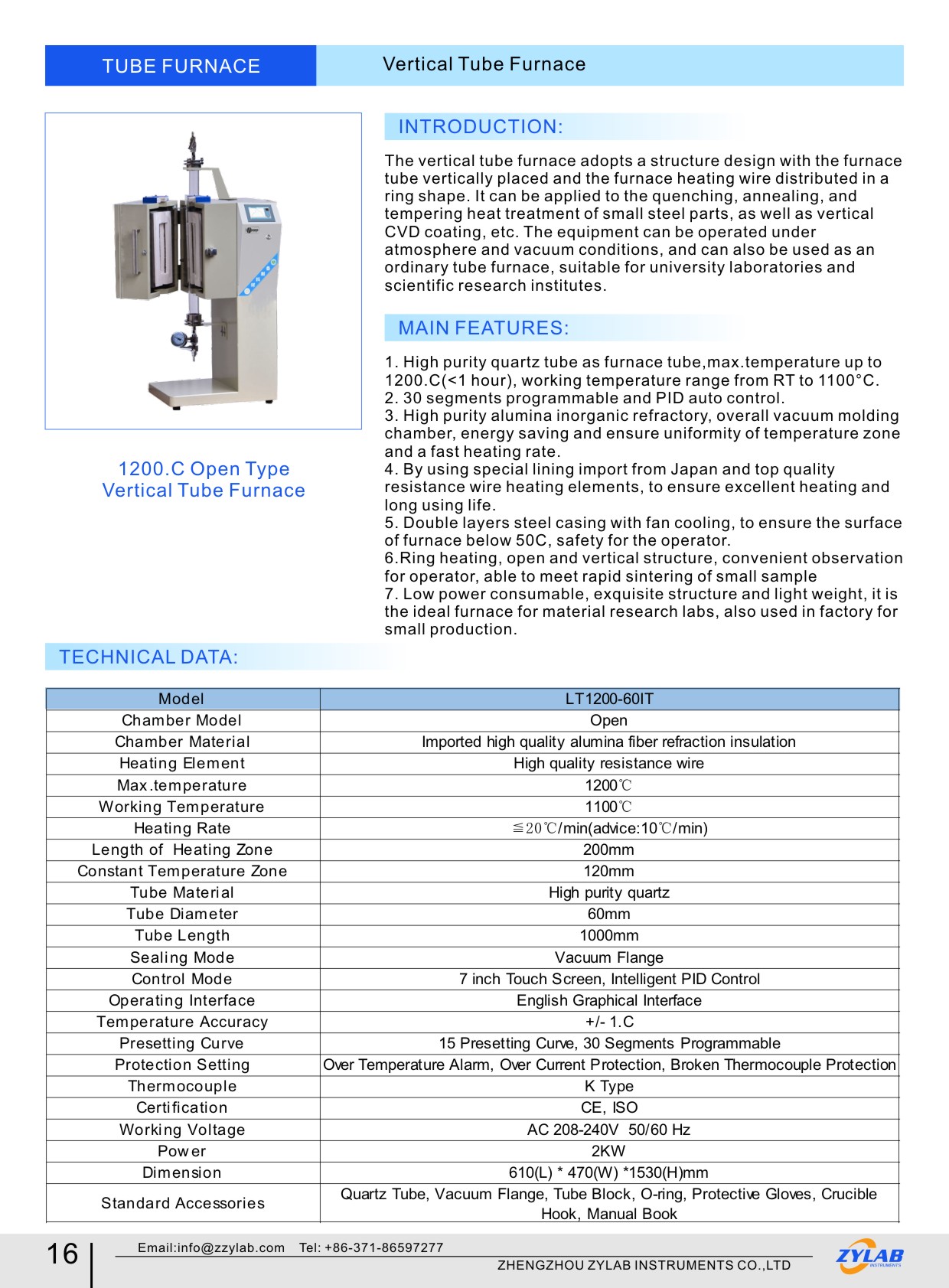

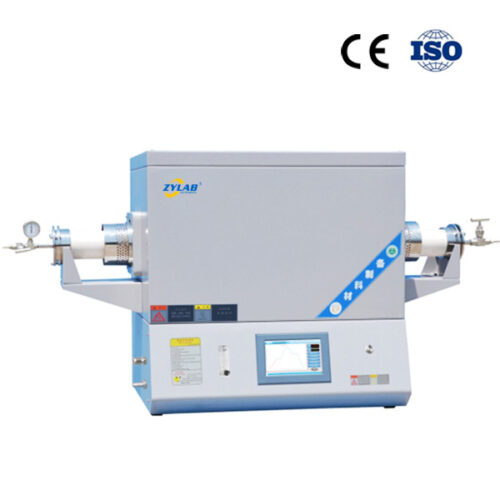

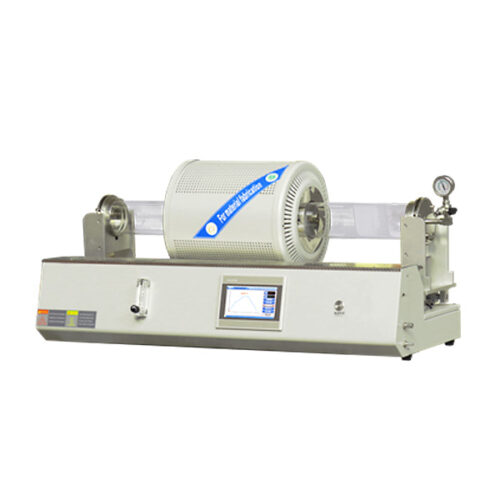

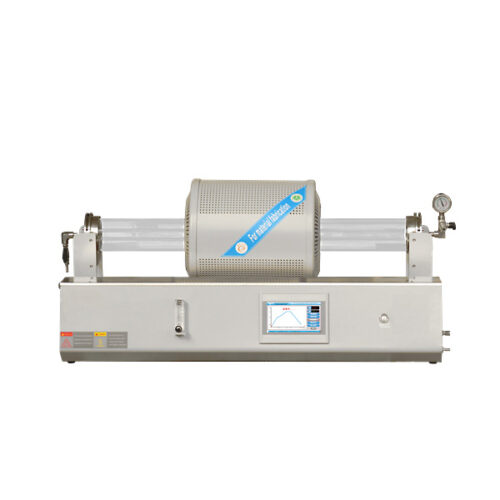

1200.C Vertical Tube Furnace

Introduction:

The vertical tube furnace adopts a structure design with the furnace tube vertically placed and the furnace heating wire distributed in a ring shape. It can be applied to the quenching, annealing, and tempering heat treatment of small steel parts, as well as vertical CVD coating, etc.

It can be operated under atmosphere and vacuum conditions, and can also be used as an ordinary tube furnace, suitable for university laboratories and scientific research institutes.

Main Features:

1.High pure quartz tube as furnace tube, max. temperature 1200.C(<1hour), continue working temperature Rt –1100.C.

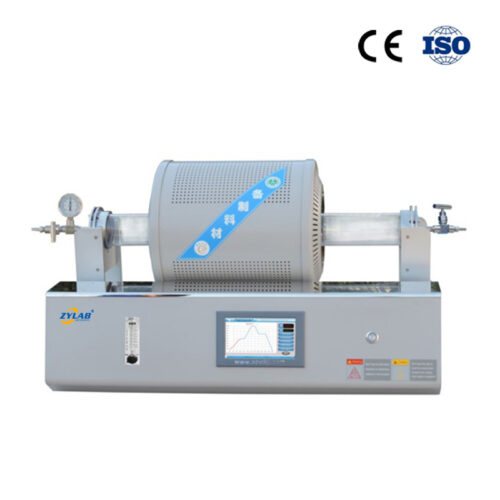

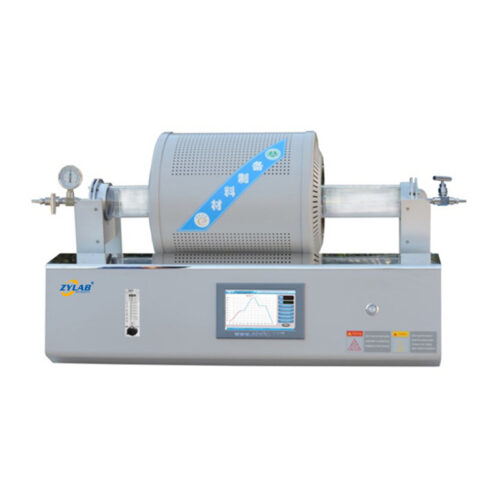

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and PID auto control.

4. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

5. By using special lining import from Japan and top quality resistance wire heating elements, to ensure excellent heating and long using life.

6. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50C, safety for the operator.

7.Ring heating, open and vertical structure, convenient observation for operator, able to meet rapid sintering of small sample

8. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for material research labs, also used in factory for small production.

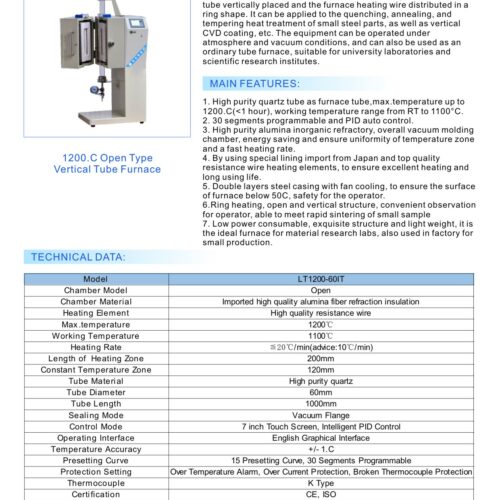

Main Specifications:

| Max.temperature | 1200℃ |

| Working Temperature | ≤1100℃ |

| Heating Rate | ≤20℃/min(advice:10℃/min) |

| Heating Zone | Single |

| Length of Heating Zone | 200mm |

| Constant

Temperature Zone |

120mm |

| Tube Material | High purity quartz |

| Tube Diameter | 60mm |

| Tube Length | 1000mm |

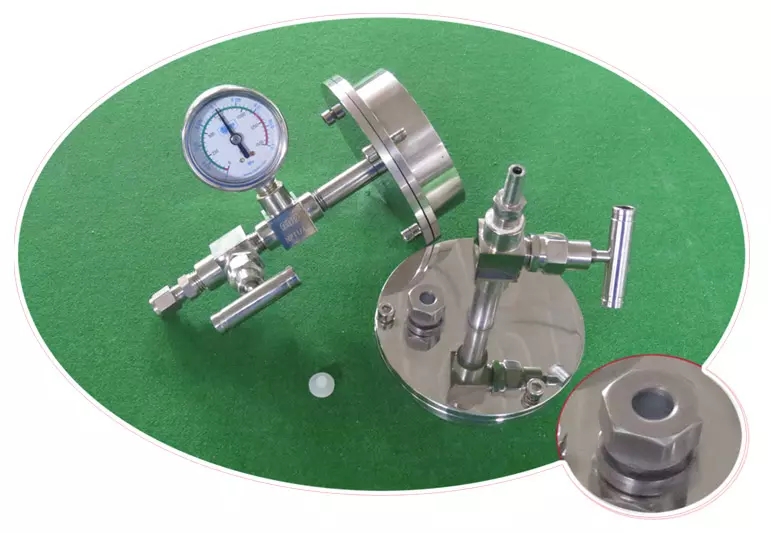

| Sealing Mode | Vacuum Flange |

| Vacuum | ≤10pa |

| Control Mode | 7 inch Touch Screen, Intelligent PID Control |

| Operating Interface | English Graphical Interface |

| Temperature Accuracy | +/- 1.C |

| Presetting Curve | 15 Presetting Curve, 30 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Protection |

| Thermocouple | K Type |

| Certification | CE, ISO |

| Working Voltage | AC 208-240V 50/60 Hz |

| Power | 2KW |

| Dimension | 610(L) * 470(W) *1530(H)mm |

| Standard Accessories | Quartz Tube, Vacuum Flange, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

| Warranty | 18 months(not including consumable parts, such as quartz tube, heating elements, thermocouple), lifetime support. |

Which kinds of industry can use this Vertical Tube Furnace?

College & Universities, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics, Ceramic, etc.

Applications:

It can be applied to the quenching, annealing, and tempering heat treatment of small steel parts, as well as vertical CVD coating, etc.

Can be operated under atmosphere and vacuum conditions, and can also be used as an ordinary tube furnace, suitable for university laboratories and scientific research institutes.