ZYLAB Vacuum Tungsten Sintering Furnace

Introduction

The ZYLAB Vacuum Tungsten Sintering Furnace is a high-performance vertical vacuum resistance furnace designed for sintering and annealing metal compounds, ceramics, and inorganic materials in a vacuum or controlled atmosphere. It is also suitable for the heat treatment of metal materials.

This batch-operated furnace features a bottom-loading structure, ensuring uniform heating and precise temperature control.

Key Features

-

Single-Chamber Vertical Structure

-

Composed of a furnace body, lid, bottom, lifting mechanism, heating elements, vacuum system, temperature field, gas supply system, water cooling system, and electrical control system.

-

-

Dual-Layer Water-Cooled Furnace Body

-

Constructed with upper and lower welded stainless steel flanges in a cylindrical shape.

-

Inner wall: 304 stainless steel with fine polishing to ensure high vacuum levels.

-

Outer wall: 304 stainless steel with sandblasted treatment for durability.

-

Integrated water cooling system between the inner and outer layers for efficient heat dissipation.

-

O-ring vacuum sealing with fluororubber gaskets to maintain high vacuum levels, with water-cooled flanges preventing gasket aging due to high temperatures.

-

Features a side thermocouple for monitoring, an observation window, gas inlet, two electrode interfaces, and a vacuum exhaust port.

-

-

Water-Cooled Furnace Lid

-

Designed with dual-layer water cooling for both the large and small central furnace lids.

-

Inner wall: 304 stainless steel with fine polishing for optimal vacuum conditions.

-

Outer wall: 304 stainless steel welded with flanges, integrated with a water cooling system.

-

Large furnace lid: Bolt-locking structure with O-ring vacuum sealing to ensure vacuum integrity.

-

Equipped with a tungsten-rhenium thermocouple port, safety valve, and exhaust port.

-

The small furnace lid features a quick-release locking system for easy operation.

-

-

Furnace Bottom & Lifting Mechanism

-

Shares the same dual-layer water-cooled design as the furnace lid.

-

Features a sample platform on the small furnace bottom, supporting bottom-loading and unloading.

-

Lifting system is integrated with linear guide rails for smooth and stable movement.

-

-

Vacuum Acquisition & Measurement System

-

Equipped with a K-100 diffusion pump with a cold trap and a TRP-36 direct-coupled mechanical pump.

-

Includes vacuum pipelines, manual butterfly valves, vent valves, and vacuum pressure gauges for precise control.

-

-

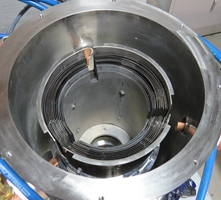

Temperature Field & Heating System

-

Uses high-purity tungsten mesh as the heating element, vertically suspended inside the furnace.

-

Three tungsten electrodes extend perpendicularly from the tungsten mesh and connect externally via water-cooled copper electrodes to the transformer for power supply.

-

Applications of Vacuum Tungsten Sintering Furnace

1. Sintering & Processing of High-Performance Ceramics

-

Transparent Ceramics – High-purity ceramics such as transparent alumina (Al₂O₃) and magnesia (MgO).

-

Technical Ceramics – Used for dense sintering of high-purity oxides and advanced ceramic components.

2. Tungsten & Refractory Metal Sintering

-

Tungsten (W) & Molybdenum (Mo) Products – Suitable for vacuum sintering of tungsten electrodes, molybdenum components, and high-density refractory metal parts.

-

Alloys & Composites – Suitable for high-density tungsten alloys and refractory metal composites.

3. Vacuum Degassing & Brightening of Metals

-

Removes impurities, gas inclusions, and oxides, ensuring high-purity metal surfaces.

-

Used for electronic-grade tungsten, molybdenum, and specialty metal refining.

4. High-Temperature Physical & Chemical Property Testing

-

Supports material research on phase transformations, thermal expansion, and mechanical properties.

-

Used in universities, research institutes, and material development laboratories.

5. Vacuum Sintering & Annealing of Metal Compounds & Inorganic Materials

-

Enables precise thermal processing of metal-ceramic composites, carbide tools, and inorganic compounds.

-

Supports annealing treatments to enhance material properties under vacuum or inert gas atmospheres.

Technical Specifications of Vacuum Tungsten Sintering Furnace

| Model | B2200 | |

| Electrical Specifications | AC 3*380V / 50Hz | |

| Rated Power | 30 kW | |

| Maximum Temperature | 2200°C (Typical Operating Temperature: 2000°C) | |

| Main Control Temperature | 2200°C (Accuracy: ±0.5°C) | |

| Heating Element | Tungsten Cage, Ring-Shaped Sealed Heating Structure | |

| Chamber Material | Multi-layer metal insulation shield composed of tungsten plates, high-temperature molybdenum plates, and double-layer stainless steel (304) | |

| Sealing & Cooling System | Water-cooled stainless steel sealing flange with cooling device to prevent O-ring aging; equipped with vacuum port, observation window shielding, electrode feedthrough, and lifting device | |

| Temperature Sensor | WRe Thermocouple Φ0.5×380mm | |

| Gas Inlet Pipe Diameter | Φ8mm | |

| Gas Pressure | ≤0.015 MPa | |

| Gas Type | Argon (Ar), Nitrogen (N₂) | |

| Gas Flow System | Pipeline system consisting of pipes, solenoid valve, and glass rotor flowmeter (7L/min) | |

| Furnace Structure | Double-layer water-cooling structure; internal chamber polished stainless steel (304), outer layer high-quality stainless steel; flange sealing with O-ring vacuum sealing | |

| Bottom Cover & Lifting Mechanism | Stainless steel circular bottom cover with tungsten rod, material tray, positioning columns, and insulation positioning columns; quick-release cylinder mechanism for loading/unloading | |

| Insulation Shield & Cover | Multi-layer metal insulation shield (tungsten plates, high-temperature molybdenum plates, stainless steel 304); shielding cover and small cover use the same material structure; load-bearing platform made of 8mm thick tungsten plate with tungsten support columns | |

| Ultimate Vacuum (Cold State) | 6.67 × 10⁻³ Pa | |

| Lifting System | Dual-layer sliding rail structure, C7 high-torque ball screw, SPY aluminum-supported hard light-axis linear guide, 57CM23 closed-loop stepper motor, high-speed precision operation with adjustable feed rate and harmonic reduction for stable material advancement | |

| Sintering Process Control | Stores up to 15 process curves, including temperature settings, sintering completion alarms, and automatic experiment report export | |

| Functional Capabilities |

|

|

| Remote & Safety Control |

|

|

| Overall Dimensions | 1300 × 2100 × 1150 mm | |

| Heating & Insulation System |  |

Corrosion-resistant graphite heater / tungsten-molybdenum heater |

| Control System |  |

|

| Temperature Accuracy | ±1°C | |

| Service & Warranty | One-year warranty with lifetime technical support (excludes consumables such as process tubes and O-rings) | |

Operational Precautions

-

Temperature Monitoring: Regularly check the furnace lid, body, bottom, and water-cooled electrodes. If they become too hot to touch, stop heating immediately and check the cooling water system.

-

Vacuum Maintenance: If the vacuum cannot be reached, inspect the diffusion pump oil for oxidation and the mechanical pump for aging; replace if necessary.

-

Gas Filling Precautions: Monitor the vacuum pressure gauge while filling gas. Avoid exceeding atmospheric pressure (keep at approximately -50Pa). Gas expands when heated, so if near positive pressure, use the mechanical pump to remove excess gas.

-

Material Loading: Avoid contact with the graphite heating element (especially the grooved sections), as it becomes fragile after high-temperature operation.

-

Cleaning & Maintenance: Regularly clean the interior and exterior of the furnace and maintain the vacuum valves to ensure optimal performance.

-

Cooling System Check: After starting the water pump, verify that all valves are fully open and that there are no leaks in the water pipes. Fix any issues immediately.

For More Content

Please read our blog: The Role of Vacuum Atmosphere Tungsten Heating Furnaces in Critical Metal Materials Research

For More Options on Vacuum Furnaces

Please visit our website [Vacuum Furnaces Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]