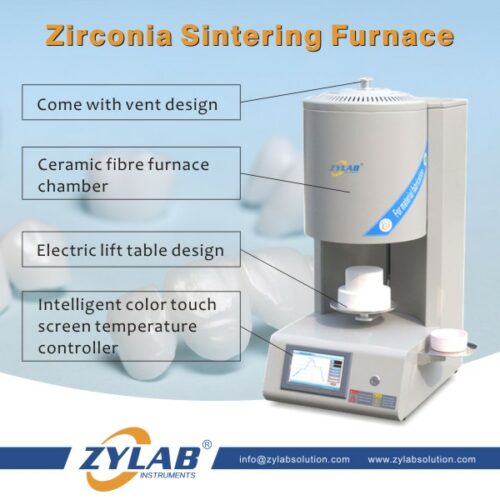

High Quality 3D Printing Vacuum Sintering Furnace

Introduction:

The specialized vacuum sintering furnace for 3D printers is widely used for the heat treatment of metal materials such as titanium alloys, pure titanium, cobalt-chromium alloys, cobalt-chromium-tungsten alloys, cobalt-chromium-molybdenum alloys, aluminum alloys, stainless steel, and more under low vacuum and protective atmospheres. It is also suitable for annealing, and brazing processes required for materials such as high-speed steel, alloy molds, and soft magnetic alloys in a vacuum atmosphere.

Features and Benefits of Vacuum Sintering Furnace:

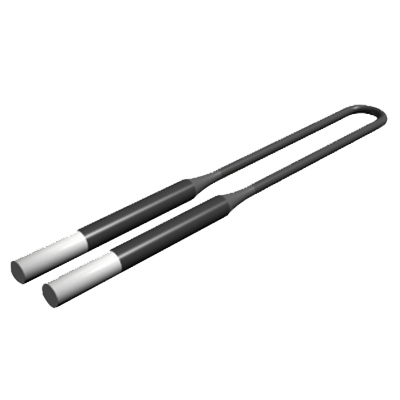

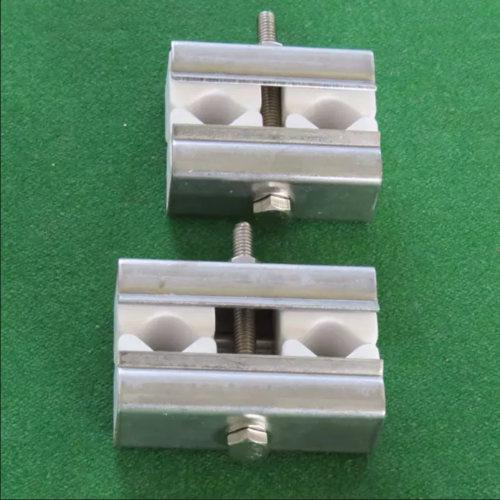

- Heating Elements: Utilizes or27A17M02 or silicon carbide and molybdenum disilicide heating elements. The imported high-temperature reflective coating material ensures uniform temperature distribution while maintaining a clean heating space.

- Touchscreen Control: Equipped with a 7-inch touchscreen control for real-time curve collection, offering a broader expansion space. The furnace can be controlled using an Android operating system for equipment control and data storage.

- Centralized Control: The required gas intake and vacuum levels during operation can be centrally controlled via the touchscreen control system, providing convenience and efficiency.

- Energy Efficiency: The furnace chamber is made from high-purity alumina fiber formed through vacuum adsorption, making it 60% more energy.

- Customizable Chamber Size: The chamber size can be customized according to the user’s specific requirements.

Technical Specifications:

| Name | 3D Printing Supporting Vacuum Sintering Furnace | ||

| Model | VA1200-20TI-D2F | VA1500-20TI-D2F | VA1700-20TI-D2F |

| Display Mode | 7-inch Touch Screen | ||

| Chamber Material | Lightweight Alumina Fiber Refractory Insulation Material | ||

| Heating Element | Molybdenum-doped Fe-Cr-Al Alloy Heating Wire | High Purity Silicon Carbide(SiC) Rods | High Purity Silicon Molybdenum(MoSi2 Rods) |

| Maximum Temperature | 1200℃ | 1500℃ | 1700℃ |

| Working Temperature | ≤1150℃ | ≤1450℃ | ≤1650℃ |

| Heating Rate | Recommended:10℃/min | ||

| Door Opening Mode | Side Sliding Door | ||

| Chamber Dimensions | 200*200*300mm | ||

| Sealing Method | Vacuum Silicone Seal Flange | ||

| Control Mode |

|

||

| Temperature Accuracy | ±1℃ | ||

| Temperature Curve | Multi-segment “Time-Temperature Curve” Programmable | ||

| Preset Curves | Can store 15 temperature curves | ||

| Protection Settings |

|

||

| Gas Supply System | Dual Float Flowmeter (with Gas Mixing System) 60~600 ml/min | ||

| Temperature Measurement | K-type Thermocouple | S-type Thermocouple | B-type Thermocouple |

| Certification | CE | ||

| Power Supply | 220V 50/60Hz | ||

| Power | 5KW | ||

| Overall Dimensions | 650×1540×600mm(L × H × D) | ||

| After-sales Service | 12 months warranty, lifetime support | ||

| Standard Accessories | Plug, O-ring, Tools, Manual | ||

| Optional |

|

||

Applications:

The vacuum sintering furnace is extensively used for the heat treatment of hard alloys, ceramics, and powder metallurgy materials under low vacuum, reductive, and protective atmospheres. It is also suitable for annealing, and brazing processes required for high-speed steel, alloy molds, soft magnetic alloys, and other materials needing heat treatment in a vacuum atmosphere.