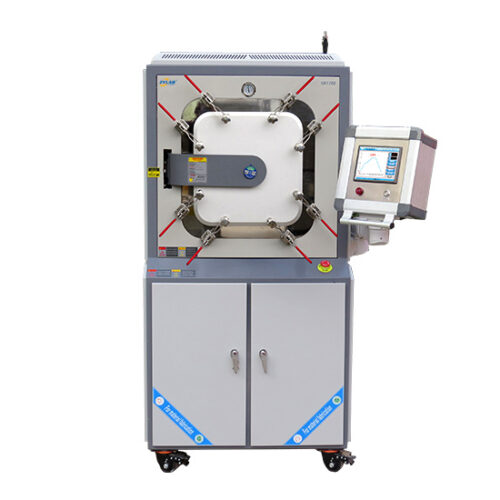

ZYLAB Vacuum Molten Salt Electroplating Furnace

Introduction

The ZYLAB Vacuum Molten Salt Electroplating Furnace is an advanced, high-temperature electrochemical processing system designed for precise molten salt electroplating applications. Featuring uniform temperature control, excellent corrosion resistance, and intelligent automation, this furnace ensures reliable and high-quality metal surface treatment.

It is widely used in materials research, aerospace, electronics, and industrial manufacturing for depositing high-purity metal coatings and achieving strong metallurgical bonding.

Key Features

-

Contactless SCR Control Module

- Utilizes a non-contact silicon-controlled rectifier (SCR) module to enhance the stability and precision of the temperature control system.

-

Uniform Heating Design

- The alloy heating elements are embedded and arranged in a ring distribution within the chamber to ensure excellent temperature uniformity throughout the furnace.

-

High-Performance Insulation Materials

- Constructed with advanced refractory and insulation materials, minimizing heat loss and significantly reducing the overall energy consumption of the equipment.

-

Multiple Electrode Connectors

- Equipped with multiple electrode terminals, allowing for easy and flexible switching during the electroplating process.

-

High-Temperature Resistant Reaction Vessel

- The reaction crucible is made from 310S austenitic chromium-nickel stainless steel, known for its superior creep resistance, oxidation resistance, and corrosion resistance at high temperatures.

-

Water-Cooled Sealing Structure

- Features a water-cooled flange and sealing system that effectively reduces the temperature of the flange, protects sealing components, and ensures airtight integrity during high-temperature operations.

Technical Specifications of Vacuum Molten Salt Electroplating Furnace

| Product Model | G1200 | |

| Electrical Power Supply | AC 220V, 2KW | |

| Maximum Temperature | 1200°C (for ≤1 hour) | |

| Continuous Working Temperature | 1100°C (continuous operation) | |

| Heating Rate | ≤ 20°C / minute | |

| Chamber Dimensions | Ø100mm x 200mm (Diameter x Depth) | |

| Temperature Control System |  |

1. Embedded control system with bilingual (Chinese-English) graphical interface 2. 7-inch full-color touchscreen with intuitive human-machine interaction 3. Non-linear temperature correction for enhanced precision 4. Stores up to 15 programmable temperature profiles for different process requirements 5. Safety features include over-temperature alarm, thermocouple break warning, and leakage protection |

| Temperature Accuracy | ±1°C | |

| Heating Elements |  |

Mo-doped Fe-Cr-Al alloy heating wires |

| Vacuum Reaction Vessel |  |

Austenitic stainless steel reaction tank (310S material), corrosion and oxidation resistant |

| Net Weight | 80KG | |

| Service Support | One-year warranty with lifetime support (warranty excludes consumable parts such as heating elements and thermocouple). | |

Applications

-

Molten Salt Electroplating

- Deposition of metals such as aluminum, magnesium, titanium, and rare earth metals in molten salt electrolytes.

- Production of dense, uniform, and strongly bonded metallic coatings on complex-shaped components.

- Ideal for coating refractory metals or substrates that require high-temperature electrochemical processing.

-

Electrochemical Metallurgy

- High-temperature molten salt electrolysis for extracting and refining reactive metals.

- Laboratory-scale simulation of industrial processes like aluminum and magnesium smelting.

- Synthesis of advanced alloys through electrodeposition techniques.

-

Surface Modification and Diffusion Coating

- Creating diffusion layers through solid-state diffusion between the deposited layer and the substrate, enhancing surface hardness, wear resistance, and corrosion resistance.

- Production of protective coatings for aerospace, automotive, and energy applications.

-

High-Temperature Electrolysis Research

- Investigation of electrochemical processes in molten salts for materials discovery and energy storage applications.

- Development of novel electrode materials and electrolytes for molten salt systems.

-

Advanced Materials Processing

- Fabrication of functional coatings, including thermal barrier coatings (TBCs) and corrosion-resistant layers.

- Research on high-temperature ionic conductors and molten salt chemistry.

|

|

Why Choose ZYLAB Vacuum Molten Salt Electroplating Furnace?

-

Advanced Temperature Control: Guarantees consistent and reliable results in high-temperature electrochemical processes.

-

Safe Operation: Integrated real-time monitoring ensures a safe working environment.

-

Customizable Options: Tailored designs available to meet specific research or production requirements.

-

Global Service & Support: ZYLAB provides professional technical support and lifetime service.

|

|

Click Here to View:How Laboratory Molten Salt Electric Heating Furnaces Are Transforming the Aluminum Electrolysis Industry

Additionally, we provide molten salt electrolysis furnace designed for metal refining and smelting applications. For more tube furnaces, box furnaces, vacuum furnaces, and other high-temperature furnaces, click here to view!