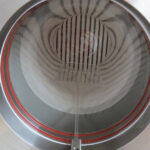

1100.C Vacuum Atmosphere Sintering Furnace with Quartz Clean Chamber

Introduction

This series of vacuum atmosphere sintering furnaces features a high-purity quartz reaction chamber capable of achieving high vacuum conditions. Its enclosed wrap-around heating design ensures rapid heating, precise temperature control, and uniform temperature distribution.

Widely used for the heat treatment of materials such as hard alloys, ceramics, and powder metallurgy in rough vacuum states, reducing atmospheres, or protective atmospheres. Additionally, the furnace is equipped with a proprietary touchscreen control system, enhancing work efficiency. The furnace chamber can be customized according to user requirements.

Features and Benefits

- High-Purity Quartz Chamber: Achieves high vacuum experimental conditions.

- Wrap-Around Heating Design: Rapid heating, precise control, and uniform temperature distribution.

- Versatile Applications: Suitable for both vacuum and atmosphere sintering.

- Stable and Reliable Control: Easy operation with comprehensive safety measures.

- Advanced PID Control: Self-learning fuzzy control maintains temperature accuracy within ±1°C.

- High-Quality Insulation: Lightweight alumina fiber material enhances insulation, reducing energy consumption.

- IoT Functionality (WiFi): Enables remote monitoring and operation via mobile phone or computer.

- Data Storage: Retains important sintering parameters for up to 30 days (based on 8 hours of daily use).

- Recipe Function: Stores up to 20 pre-set recipes.

- Networking Capability: Connects to a host computer via RJ45 interface using the TCP/IP protocol (software installation required on the host computer).

Technical Details of Vacuum Atmosphere Sintering Furnace

| Model | V1200-30 |

| Power Supply | AC380V 10KW |

| Heating Element | Premium Fe-Cr-Al alloy wire |

| Temperature Accuracy | ±1°C |

| Thermocouple | K-type |

| Max Temperature | 1100°C |

| Heating Zone | High-purity quartz tube φ300×690mm |

| Furnace Dimensions | 1100×1100×1650mm (L×W×H) |

| Recommended Heating Rate | ≤10°C/min |

| Vacuum | ≤10 Pa, pls addition order our Mechanical Vacuum Pump

Or 4.4 × 10⁻³ Pa, pls order our High Vacuum System Molecular Pump Unit |

| Control System | 1. Sintering Curve Setup: Displays dynamic sintering curves with multiple programmable profiles.

2. Scheduled Sintering: Enables unattended sintering operations. 3. Real-Time Monitoring: Displays and records sintering power and voltage data, with exportable digital records. 4. Remote Control: Supports real-time monitoring and operation of equipment status. 5. Temperature Calibration: Non-linear correction of temperature differences between the main control and sample during sintering.  |

| Gas Supply System and Pressure Measurement | Includes a mechanical pressure gauge with shock-absorbing oil and a high-precision flowmeter with one low-flow gas line. |

| Quartz Chamber and Seal |  |

| Net Weight | Approximately 300 kg |

| Service Support | Two-Year Limited Warranty with lifetime support (warranty excludes consumable parts such as the quartz chamber and O-rings). |

Detail Applications

- Hard Alloy Heat Treatment

Ideal for sintering and annealing hard alloys under vacuum or controlled atmosphere conditions to enhance material properties. - Ceramics Processing

Suitable for sintering advanced ceramics used in electronics, aerospace, and medical industries. - Powder Metallurgy

Supports the consolidation and sintering of metal powders into dense, high-strength components in protective or reducing atmospheres. - Material Development

Facilitates research and development of novel materials, including composites and functional materials, under precise thermal and atmospheric conditions. - Thin Film Deposition Studies

Enables experiments involving vacuum conditions for thin-film deposition or surface modification. - High-Temperature Chemical Reactions

Perfect for controlled experiments requiring vacuum or specific gas atmospheres to achieve desired reaction conditions. - Academic and Industrial Research

Widely used in universities, laboratories, and industries for material synthesis, analysis, and optimization.

This furnace offers exceptional precision, uniformity, and flexibility, making it a go-to choice for cutting-edge research and production in multiple fields.

For More Options on Vacuum Atmosphere Furnace

Please visit our website [Controlled Atmosphere Furnaces Collection]