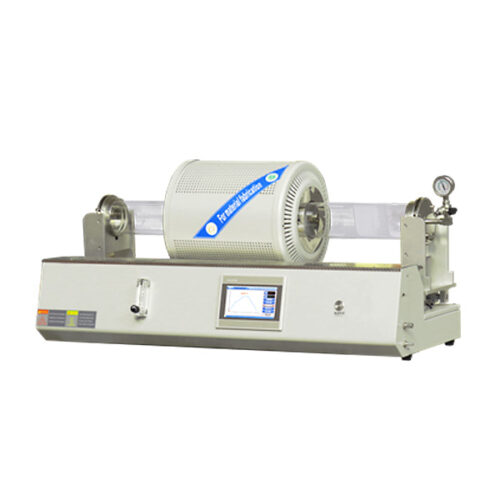

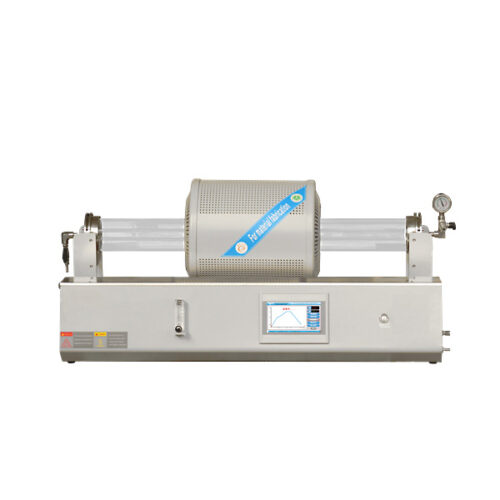

1700.C Two Zones Tube Furnace

Introduction:

This two zones tube furnace max.temperature up to 1700.C, use corundum tube as the carrier for heating and sealing. Precise and advanced touch screen auto temperature controller, high temperature accuracy, easy operation, excellent heat-insulation effect, symmetrical temperature uniform.

Is widely used for vacuum sintering, vacuum sintering under atmosphere protection,nano materials preparation, battery material preparation and other multiple research fields.

Main Features:

1. Max. Temperature 1700C, suggest working temperature RT-1650C.

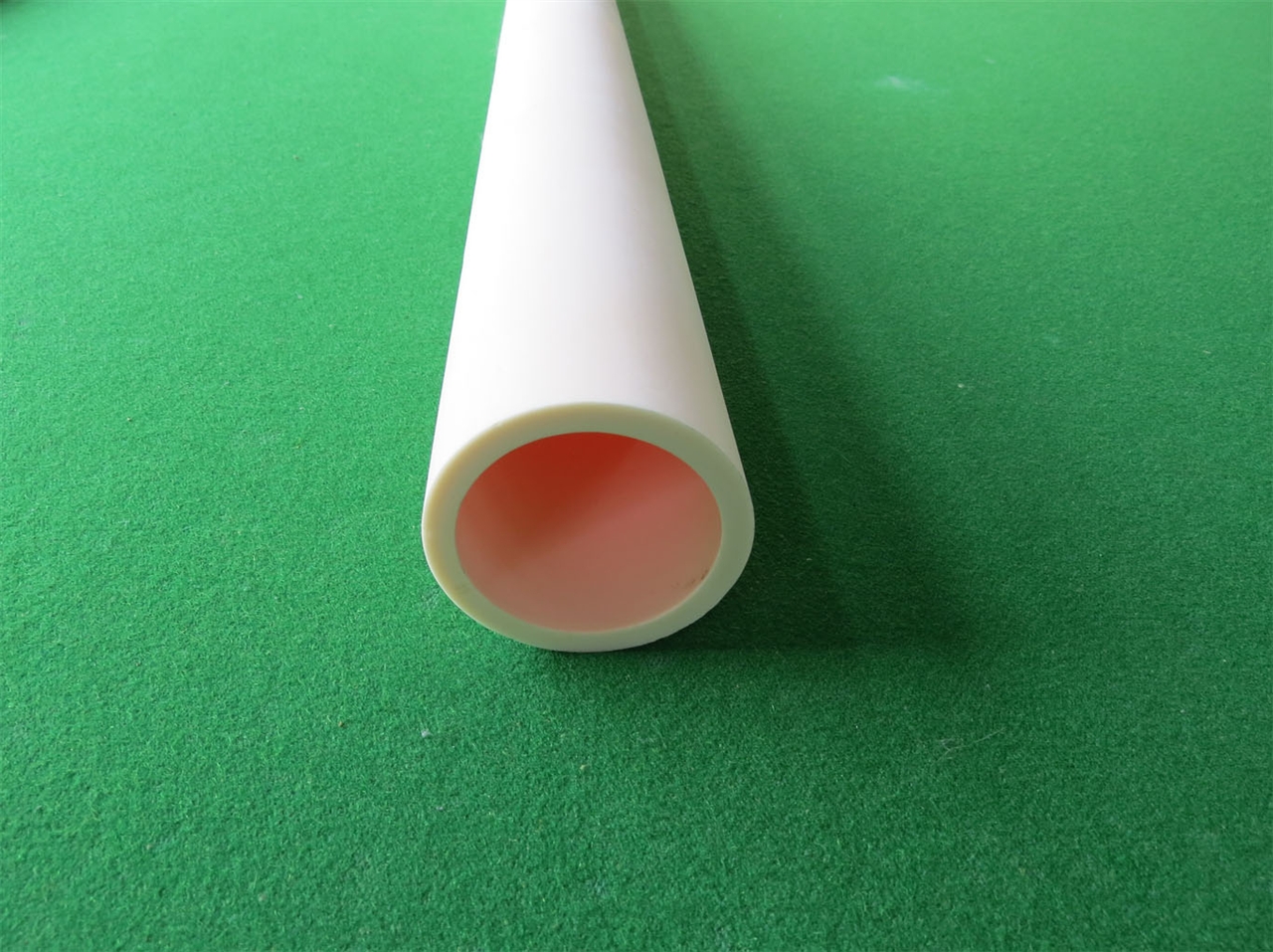

2.High purity alumina(ceramic) tube as furnace tube, with excellent corrosion resistance and high temperature resistance, longer service life.

3. 30 segments programmable and auto control.

4. Intelligent 7”Color Touch screen LCD man-machine English interface temperature controller, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

5. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

6. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

7.By using special lining import from Japan and high-purity MoSi2 heating elements with good corrosion resistance, to ensure excellent heating and long using life.

8. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

9. Come with gas flowmeter, atmosphere sintering more convenient.

10. Unique flange has a multi-function test holes, insert the corresponding electrode to test tube temperature or atmosphere environment.

11. Have two temperature zones, each can be independently controlled.

12. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for labs and production in factory.

Main Specifications of Two Zones Tube Furnace:

| Model | T1700- IIT |

| Product name | 1700.C Intelligent two zones high temperature tube furnace |

| Display mode | 7 inch color touch screen smart fuzzy PID control |

| Chamber material | Imported high quality alumina fiber refraction insulation |

| Heating element | High-purity MoSi2 heating elements with good corrosion resistance |

| Max. temperature | 1700.C (< 1hour) |

| Working temperature | ≤1650.C(continue) |

| Heating rate | 0-20.C/min |

| Length of heating zone | 230+230mm |

| Heating zone quantity | Two(dual temperature zones can be independently controlled) |

| Tube size(mm) | Optional sizes: Φ50*1200/ Φ60*1200/ Φ80*1200 |

| Temperature control | 30 segments programmable and PID auto control |

| Accuracy | ±1℃ |

| Operating Interface | English Graphical Interface |

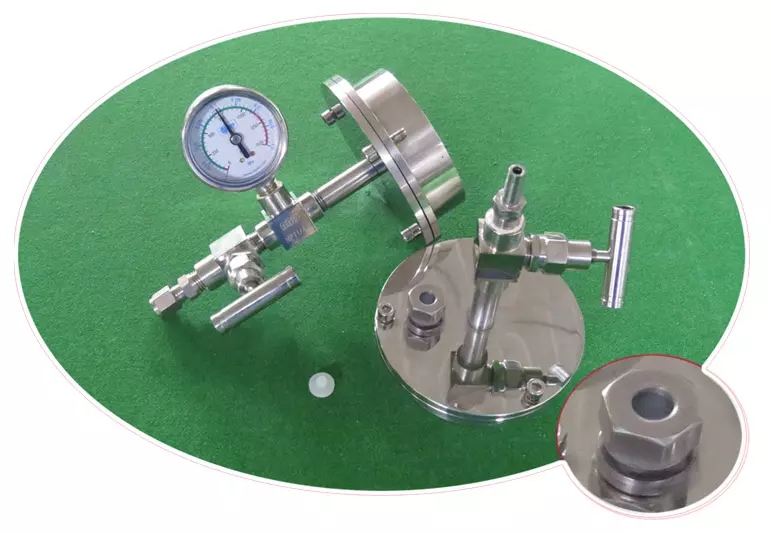

| Sealing Mode | Vacuum Flange |

| Gas tightness | 4.03×10-3pa |

| Flow control | 20-200ml/min |

| Presetting curve | 15pcs sintering curve |

| Protection setting | Over temperature alarm, Over-current protection, broken

thermocouple prompt |

| Thermocouple | B type |

| Certification | CE,ISO |

| Power | 380V 50Hz(as requirement), 7KW |

| Dimensions | 800×750×540(mm) |

| Net weight | 100kgs |

| Standard Accessories | Alumina Tube, Vacuum Flange, Vacuum Gauge, Gas Flow Meter, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

| Warranty | 12 months(not including consumable parts, such as alumina tube, heating elements, thermocouple, etc), lifetime support. |

FAQ:

Q: What is a 1700.C Two Zones Vacuum Tube Furnace?

A: A 1700.C Two Zones Vacuum Tube Furnace is a specialized high-temperature furnace designed to operate at temperatures up to 1700 degrees Celsius. It features two independent heating zones along the length of the tube, allowing for different temperature profiles to be set and controlled simultaneously. The furnace operates under low-pressure or vacuum conditions, providing a controlled atmosphere and preventing unwanted reactions with gases like oxygen, making it suitable for high-temperature processes that require a clean environment.

Q: What are the applications of a 1700.C Two Zones Vacuum Tube Furnace?

A: The 1700.C Two Zones Vacuum Tube Furnace has numerous applications in scientific research and industrial settings. Some common applications include materials science research, semiconductor processing, advanced coatings deposition, crystal growth, aerospace and defense applications, nanotechnology research, metallurgy, carbon fiber production, and high-temperature experiments in various scientific fields.

Q: What are the benefits of using a 1700.C Two Zones Vacuum Tube Furnace?

A: The benefits of using a 1700.C Two Zones Vacuum Tube Furnace include its high-temperature capability, dual-zone control for flexible temperature profiles, vacuum operation for a controlled atmosphere, precise temperature control, versatility in handling various materials and processes, reduced contamination risk, advanced materials research opportunities, improved material properties, energy efficiency, safety features, and support for research and development in various fields.

Q: How does a 1700.C Two Zones Vacuum Tube Furnace work?

A: The furnace operates by creating a vacuum or low-pressure environment inside the tube or chamber. It uses two independent heating zones along the tube to allow for different temperature profiles. The heating elements generate and maintain the high temperatures required for the heat treatment processes. A programmable temperature controller ensures precise and uniform temperature control throughout the process, and safety features are included to ensure safe operation.

Q: Can a 1700.C Two Zones Vacuum Tube Furnace be used for large-scale industrial applications?

A: The use of a 1700.C Two Zones Vacuum Tube Furnace in large-scale industrial applications may vary depending on the specific requirements and scale of the operation. While this type of furnace is commonly used in laboratory settings and small-scale research, larger industrial processes might require different equipment. In some cases, specialized and larger industrial vacuum furnaces may be more suitable for mass production and high-volume processing.

Q: How to choose the right vacuum tube furnace for specific applications?

A: When choosing a vacuum tube furnace, consider factors such as the desired temperature range, dual-zone capability if needed, vacuum level requirements, programmable temperature controller, safety features, and compatibility with the materials and processes you intend to work with. Consult with the furnace supplier or manufacturer to ensure the selected model meets your specific requirements and application needs.

Q: Can a 1700.C Two Zones Vacuum Tube Furnace be used for educational purposes?

A: Yes, a 1700.C Two Zones Vacuum Tube Furnace can be used for educational purposes in academic settings. It can be valuable for teaching high-temperature processes, materials science, and other scientific principles. Educational institutions may use such furnaces to provide students with hands-on experience and demonstrate various scientific concepts related to high-temperature applications.

Click to see more content:

Understanding Tube Furnace Temperatures: Medium vs. High-Temperature Applications

The Role of 1700°C Tube Furnace in Material Preparation