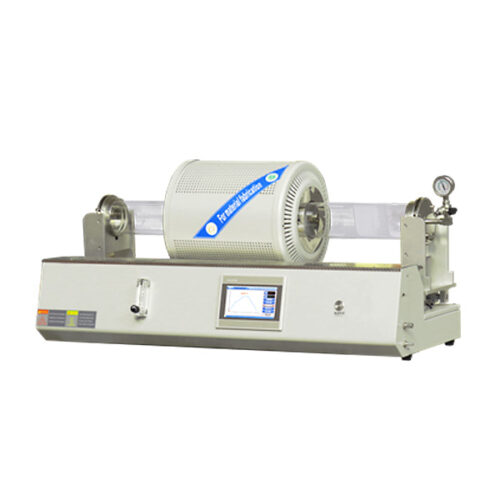

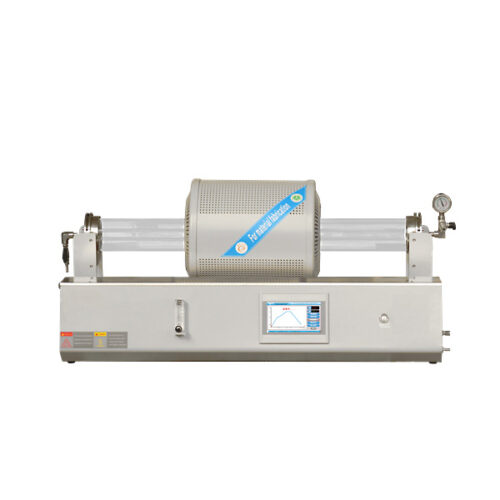

Advanced Large-Diameter Tube Furnace for LED Phosphor Synthesis

Introduction

The Large-Diameter Tube Furnace for LED Phosphor is specially developed and manufactured for large workpieces or batch heat treatment production. It is primarily used in industries such as semiconductor wafer annealing, LED phosphor, substrate materials, battery materials production, and more.

The furnace tube is made of large-diameter high-purity quartz material, which can be used for both atmosphere processing and vacuum applications. It adopts intelligent PID fuzzy control and multi-point temperature measurement to ensure uniform temperature distribution inside the furnace.

Features and Benefit

1.Ultra-large pipe diameter, ultra-long temperature zone, and multi-point temperature control to ensure uniform temperature distribution of the equipment; which can be used in laboratories and production enterprises.

2.High purity quartz tube or stainless steel tube as furnace tube, Max. Temperature 1200.C, working temperature Rt –1100.C.

3.30 segments programmable Precise temperature control. and auto control.

4.7”Color Touch screen LCD intelligent man-machine English interface, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

5.Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different processes.

6.High-purity Inorganic Al2O3 fiber refractory insulation material, vacuum adsorption molding, excellent insulation effect, greatly reducing the power consumption of equipment; Safe and environmentally friendly.

7.Full fiber structure, annular heating, energy saving and high efficiency.

8.Perfect protection measures for over-temperature, thermocouple-break, leakage and so on, safe and worry-free!

9.Double-layer thermal insulation structure with air-cooling, to ensure the surface of furnace below 50C, safety for the operator.

10.Equipped with a constant pressure system, which can automatically adjust the pressure in the furnace tube.

11.Quick-open stainless steel sealing flange is convenient for users to take and unload materials.

Technical Specifications of Tube Furnace for LED Phosphor Synthesis

| Model | T1200-152T2 | T1200-152T3 | T1200-215T3 |

| Power Supply | AC380V 10KW | AC380V 15KW | AC380V 24KW |

| Max.temp | 1200 ℃ (<1hour) | ||

| Working temp | 1100 ℃ (Continuous) | ||

| Heating Rate | ≤ 20°C/min | ||

| Heating Zone Length | 600mm | 1100mm | 1100mm |

| Furnace Tube Size | Φ152*1200mm | Φ152*1650mm | Φ215*1660mm |

| Intelligent Touch Screen Control System | 1. PID automatic control and auto-tune function. 2. 30 programmable segments for precise control. 3. Built in protection for over-heated and broken thermal couple, and leakage. 4. Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. 5. Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes.  |

||

| Temperature Accuracy | +/- 1 ℃ | ||

| Heating Element | Mo-doped Fe-Cr-Al Alloy | ||

| Sealing System

Quick-opening stainless steel sealing flanges |

|

|

|

| Vacuum: ≤10Pa (Mechanical Pump) | |||

| Pressure Measurement and Monitoring |  |

Intelligent digital pressure gauge for precise pressure display and adjustable pressure settings. It works with a high-precision, high-stability solenoid valve to maintain stable internal furnace tube pressure. Additionally, the device is equipped with a backup pressure protection system for enhanced safety and reliability. | |

| Gas Supply System | Floater flow meter to control gas flow rate, integrated with the equipment. Leakage testing is performed before delivery | ||

| Net Weight | 85KG | 105KG | 215KG |

| Service Support | 1-year warranty with lifetime support (does not cover consumables such as furnace tubes and seals). | ||

Precautions for Use

- When using the equipment, the internal pressure of the furnace tube must not exceed 0.125MPa (absolute pressure) to prevent equipment damage.

- Gas cylinders have high internal pressure. When feeding gas into the furnace tube, a pressure-reducing valve must be installed on the gas cylinder. It is recommended to select a small pressure-reducing valve with a range of 0.01MPa-0.15MPa for more accurate and safer operation.

- When the furnace temperature exceeds 1000°C, the furnace tube should not be under vacuum. The internal pressure of the furnace tube should be at atmospheric pressure.

- During heating experiments, it is not recommended to close the gas inlet and outlet valves at the furnace tube flanged ends. If gas valves must be closed during sample heating, constantly monitor the pressure gauge reading. The absolute pressure gauge reading should not exceed 0.15MPa.

Which kinds of industry can use this furnace?

College & Universities, Institute, enterprise, Chemistry, Electronics,etc

For research and manufacture of semiconductor, LED phosphors, substrate materials, and battery materials, etc

Applications

The Large-Diameter Tube Furnace for LED Phosphor is specially developed and manufactured for large workpieces or batch heat treatment production. It is primarily used in industries such as semiconductor wafer annealing, LED phosphor, substrate materials, battery materials production, and more.

For More Options on High Temperature Furnaces

Please click here [High Temperature Furnaces Collection]