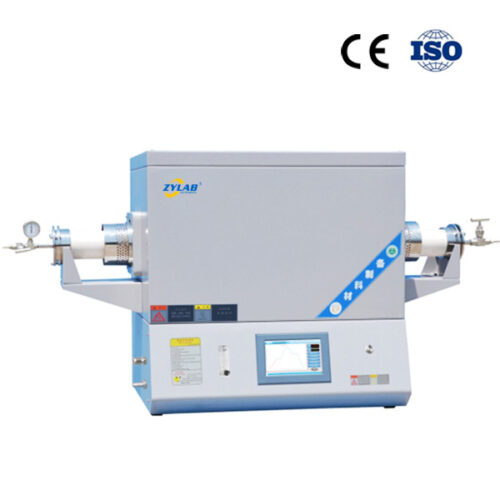

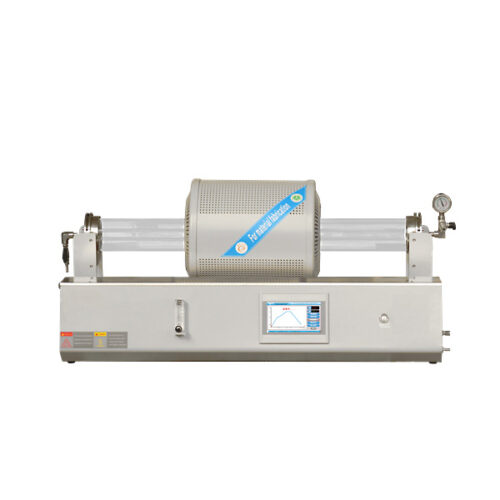

High Temperature Tube Furnace 1500.C

Introduction:

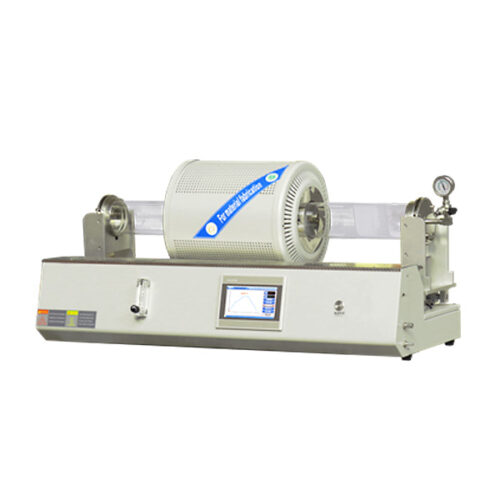

This high temperature tube furnace 1500.C is widely used in CVD experiment whose reaction temperature is around 1400 degree Celsius. It can also used in vacuum sintering, sintering under vacuum atmosphere protection, nano material preparation, battery material preparation and other research field.

Features and Benefits:

1. Max. Temperature 1500.C, suggest working temperature RT-1450.C.

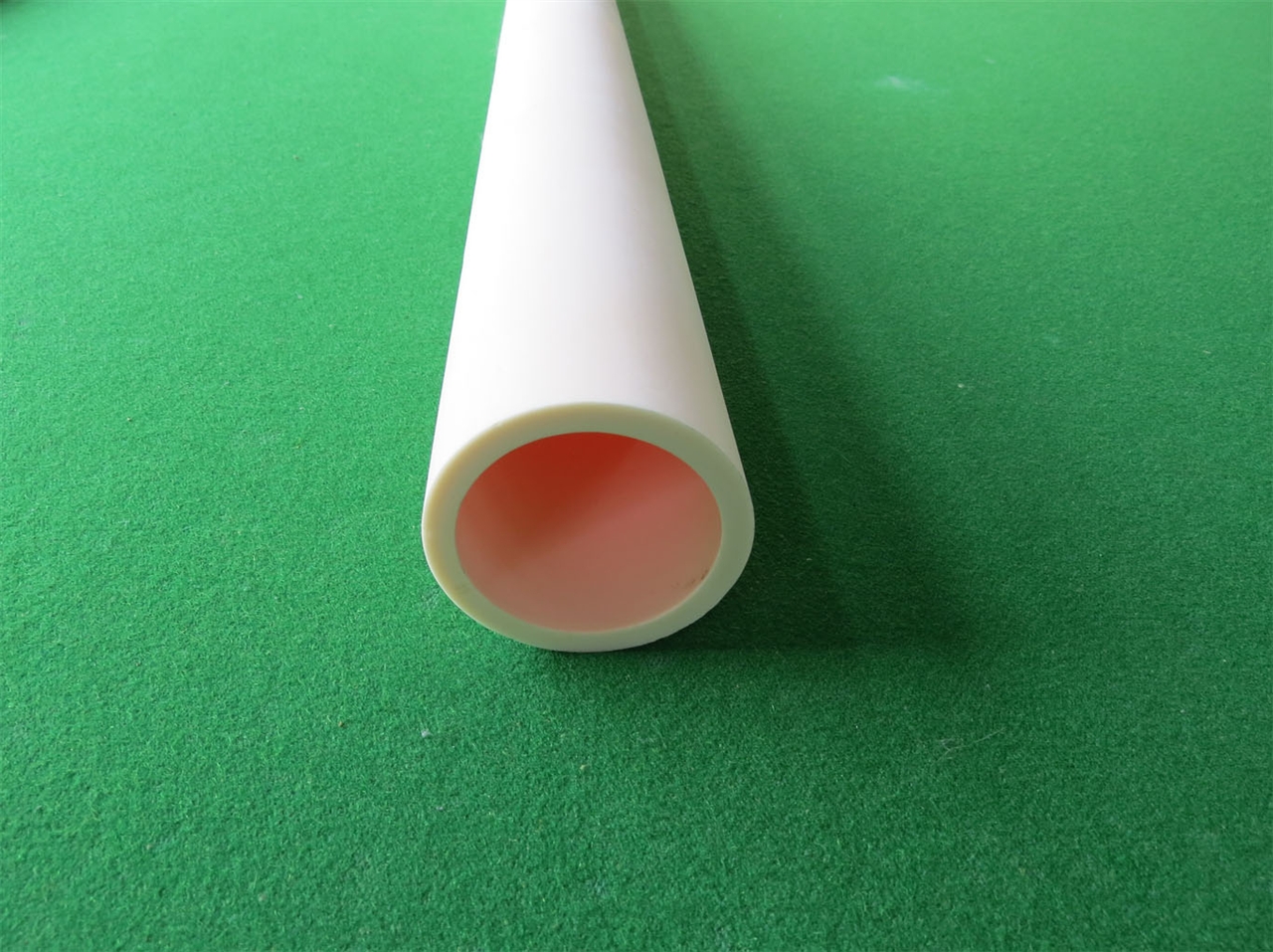

2.High purity alumina(ceramic) tube as furnace tube, with excellent corrosion resistance and high temperature resistance, longer service life.

3. 51 segments programmable and auto control.

4. Intelligent 7”Color Touch screen LCD man-machine English interface temperature controller, more intuitive and convenient operation, the graph of sintering curve with temperature changes makes you clear at a glance.

5. Can presetting 15 sintering curves to avoid the trouble caused by repeated settings of different experimental processes.

6. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

7.By using special lining import from Japan and high quality sic heating elements, to ensure excellent heating and long using life.

8. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

9. Come with gas flowmeter, atmosphere sintering more convenient.

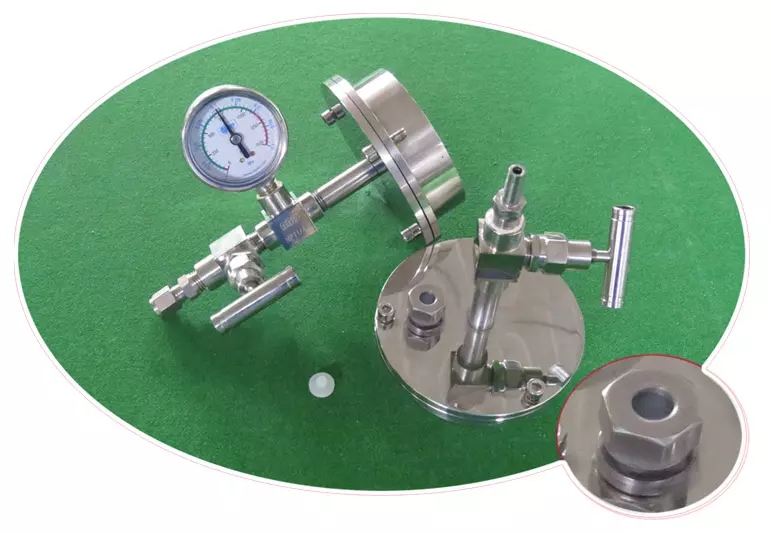

10. Unique flange has a multi-function test holes, insert the corresponding electrode to test tube temperature or atmosphere environment.

11. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for labs and production in factory.

Technical Parameters of Tube Furnace 1500.C:

| Model | T1500- IT |

| Product Name | High Temperature Tube Furnace 1500.C |

| Display Mode | 7 inch color touch screen smart fuzzy PID control |

| Chamber Material | Imported high quality alumina fiber refraction insulation |

| Heating Element | High-purity sic heating element with excellent acid and corrosion resistance |

| Max.temperature | 1500℃ |

| Continue

Working Temperature |

≤1450℃ |

| Heating Rate | ≤20℃/min(advice:10℃/min) |

| Heating Zone | One |

| Length of Heating Zone | 310mm(optional:480mm) |

| Tube Material | High Purity Alumina(Corundum tube) |

| Tube Size(mm) | Dia80x1000mm

Optional tube size: Φ50*1000/ Φ60*1000/Φ50*1200/ Φ60*1200/ Φ80*1200 |

| Sealing Mode | Vacuum Flange |

| Vacuum level | ≤10Pa (mechanical pump) |

| Pressure Measurement and Monitoring | Utilizing a mechanical pressure gauge with shock-absorbing oil to introduce damping effects during pressure fluctuations, reducing the back-and-forth oscillation of the pointer. |

| Gas supply control | Gas flow rate is controlled using a float flowmeter, integrated seamlessly with the equipment, and subjected to leakage testing before leaving the factory.

Control range: 20-200ml/min |

| Control Mode | Smart PID Control |

| Temperature Accuracy | +/- 1.C |

| Operating Interface | English Graphical Interface |

| Presetting Curve | 15 Presetting Curve, 51 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Prompt |

| Thermocouple | S Type |

| Power | 3kw |

| Working Voltage | 208-240V 50/60HZ(as requirement) |

| Dimensions(W*D*H) | 600x540x750mm |

| Standard Accessories | Alumina Tube, Vacuum Flange, Vacuum Gauge, Gas Flow Meter, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

| Certificate | CE, ISO |

| Warranty | 1 year (not including consumable parts, such as alumina tube, heating elements, thermocouple, etc), lifetime support. |

Which kinds of industry use this High Temperature Tube Furnace 1500.C?

College & Universities, New Material Research, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics, Ceramic, etc.

Applications:

High temperature tube furnaces with a capability of reaching 1500°C are utilized across various industries and research fields for a wide range of applications. Some of the common applications include:

Materials Synthesis:

High-temperature tube furnaces are commonly used for the synthesis of advanced materials such as ceramics, metal alloys, and composites. These furnaces provide a controlled environment for reactions to occur at elevated temperatures, allowing for the creation of materials with specific properties.

Heat Treatment:

Industries such as aerospace, automotive, and tool manufacturing utilize high-temperature tube furnaces for heat treatment processes. These processes involve heating materials to high temperatures to modify their properties, such as hardness, strength, and microstructure.

Chemical Vapor Deposition (CVD):

High-temperature tube furnaces are integral in CVD processes for depositing thin films of materials onto substrates. This technique is widely used in semiconductor manufacturing, solar cell production, and the fabrication of advanced coatings.

Graphene Production:

The synthesis of graphene, a two-dimensional material with exceptional properties, often requires high temperatures. High-temperature tube furnaces enable the controlled growth of graphene layers through processes like chemical vapor deposition (CVD) or annealing of graphene oxide.

Carbonization and Pyrolysis:

Industries involved in carbon fiber production, carbon materials, and activated carbon utilize high-temperature tube furnaces for carbonization and pyrolysis processes. These processes involve heating carbonaceous precursors to high temperatures in an inert atmosphere to produce carbon-based materials.

Research and Development:

High-temperature tube furnaces are indispensable tools in research and development laboratories across various fields. Researchers use these furnaces to investigate the properties of materials at elevated temperatures, study phase transformations, and develop new synthesis methods.

Ceramic Processing:

In ceramic research fields, high temperature tube furnaces are used for processes such as sintering, annealing, and phase transformation. These processes are critical for producing ceramic components with desired microstructures, mechanical properties, and thermal stability.

Crystal Growth:

In materials science and semiconductor industries, high-temperature tube furnaces are used for crystal growth processes. These furnaces provide controlled thermal environments conducive to the growth of single crystals for electronic and optical applications.

Thermal Analysis:

High-temperature tube furnaces are used in thermal analysis techniques such as thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). These techniques involve heating materials under controlled conditions to study their thermal behavior and properties.

Overall, the versatility and high-temperature capabilities of tube furnaces make them essential equipment in various industries, research institutions, and academic laboratories for a wide range of applications related to materials processing, synthesis, and characterization.