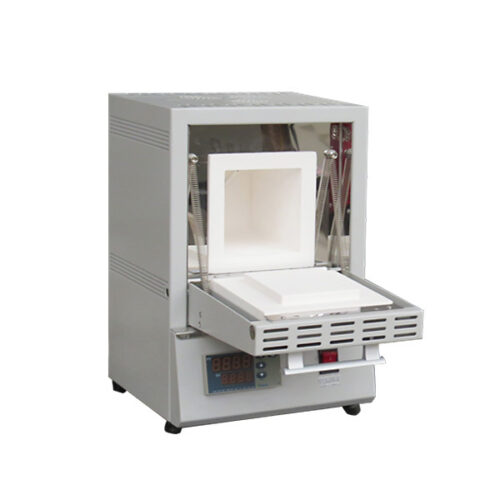

Advanced Lab Touch Screen Muffle Furnace for Research and Testing

Introduction

This Lab Touch Screen Muffle Furnace is special design for customers, ultra-high cost performance of 4.5L volumetric muffle furnace.

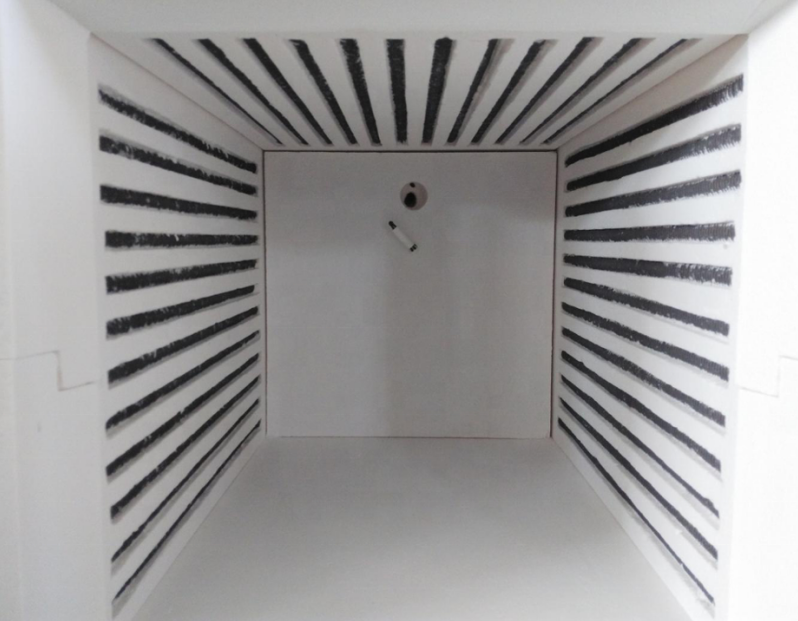

Use classical simplified design process, multi-layer alumina fiber furnace chamber, touch screen controller, accessible man-machine interaction, make operation easier!

The latest technology of molybdenum-doped iron-chromium-aluminum alloy heating wire. With the exhaust device, not only can be used for routine use, but also for wax and ashing experiments.

Key Features

1. Max. Temperature 1200C, working temperature RT-1100C.

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and auto control.

4. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

5. By using special lining and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

6.With the exhaust device(an exhaust chimney in the top of the furnace), not only can be used for routine use, but also for wax and ashing experiments.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50C, safety for the operator.

8. Low power consumable, exquisite structure and light weight, it is the ideal muffle furnace for material research labs.

Technical Specifications

| Model | M1200 |

|

Furnace structure |

•1430 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

150*150*200mm |

| Max. temperature | 1200.C(<1 hours) |

| Working temperature | Rt -1150.C |

| Intelligent Touch Screen

Temperature controller |

1. PID automatic control and auto-tune function. 2. 30 programmable segments for precise control. 3. Built in protection for over-heated and broken thermal couple, and leakage. 4. Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. 5. Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes.

|

| Heating element | Top quality resistance wire: Mo-doped Fe-Cr-Al alloy

|

| Heating rate | ≤ 20.C/min |

| Temperature accuracy | +/- 1.C |

| Thermocouple | K type |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 3 Kw |

| Dimension | 390(W)*600(H)*430(D)mm |

| Quantity / Net weight | 1set / 40kgs |

| Warranty | 12 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. |

| Certificate | CE, ISO9001 |

Which kinds of industry use this Touch Screen Muffle Furnace?

Materials Science

Metallurgy

Chemical Industry

Environmental Science

Energy Research

University Labs & Research Institutes

Applications

Ashing

- Determination of ash content in food, plastics, coal, and petroleum products

- Loss on ignition (LOI) tests

- Ash analysis in environmental and agricultural samples

Sintering

- Sintering of ceramic materials and metal powders

- Fabrication of advanced materials for electronics and energy storage

- Preparation of catalysts and membranes

Heat Treatment

- Annealing of metals and glass

- Tempering and hardening processes

- Stress relieving of mechanical components

Calcination

- Calcination of inorganic materials

- Preparation of biochar and activated carbon

- Thermal decomposition of raw materials in chemical processes

Material Testing

- Thermal stability analysis of polymers and composites

- Firing tests for refractories

- Heat resistance testing of building materials

Chemical Analysis

- Sample pre-treatment for gravimetric and quantitative analysis

- Evaporation of volatile substances

- Ashing of wastewater and sludge samples for environmental monitoring

Educational and Research Use

- Laboratory experiments in universities and research institutes

- Advanced material development projects

- Teaching equipment for thermal process studies

For More Options on Muffle Furnaces

Click here [Muffle Furnaces Collection]

For More Options on High Temperature Furnaces

Click here [High Temperature Furnaces Collection]