1200.C Three Zone CVD Tube Furnace with Electrically Controlled Opening Door

Introduction

This Three-Zone CVD Tube Furnace offers flexible combinations of gas supply and vacuum systems, making it suitable for various thin film deposition processes.

It is widely used in the semiconductor industry for depositing thin film materials, including large-area insulating materials and most metallic and metal alloy materials. Our complete CVD coating systems are ideal for use in material laboratories of universities, research institutes, environmental science fields, and more.

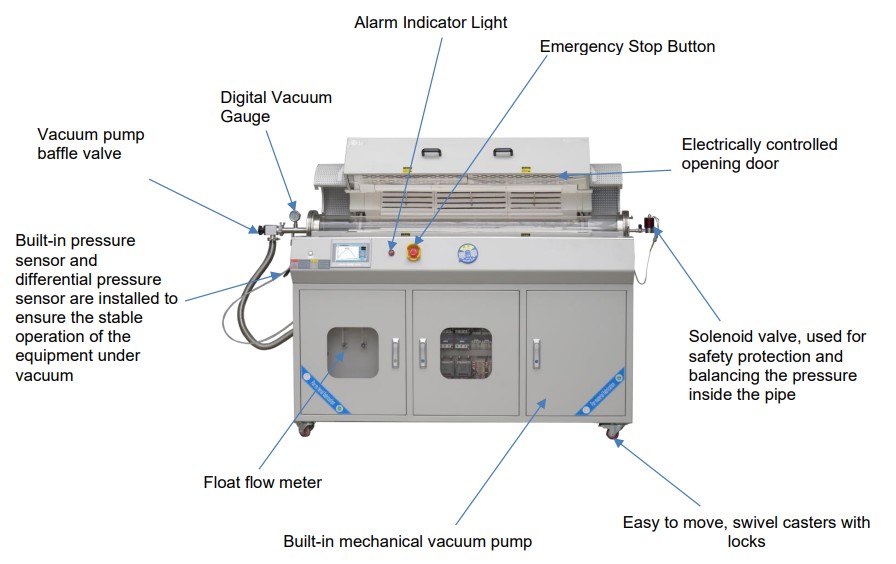

Structure of Three-Zone CVD Tube Furnace

Features of Three-Zone CVD Tube Furnace

- High-Purity Quartz Tube: Excellent corrosion resistance and high-temperature performance.

- High-Purity Al2O3 Fiber Insulation: Superior thermal insulation, reducing power consumption.

- Double-Layer Air-Cooling Structure: Efficient heat dissipation with a dual-layer air-cooling design.

- Automatic Lifting Furnace Door: Easy access with an automatic lifting system for the furnace door.

- Embedded Operating System: Bilingual (Chinese/English) interface, 7-inch touchscreen, real-time heating display, automatic report generation, and unlimited data export.

- Integrated System: Includes multi-path gas supply, three-zone heating, and high-vacuum system.

Technical Parameters

| Product Name | Three Zone CVD Tube Furnace With Vacuum Pump | |

| Model | O1200-120T3GD2F | |

| Heating system

|

Furnace dimensions | L×W×H=1700mm×760mm×1200mm |

| Reaction chamber dimensions | High-purity quartz, outer diameter 120mm, inner diameter 112mm*(200+400+200)mm | |

| Main control working temperature | ≤1150℃ | |

| Opening method | Electrically open or close the furnace chamber through screen buttons for easy viewing of sample position and replacing the furnace tube | |

| heating rate | Recommended ≤20℃/min | |

| heating element | HRE (High-Resistance Element) | |

| furnace chamber material | Alumina fiber insulation refractory material | |

| temperature zone length | 200+400+200mm | |

| Temperature control accuracy | ±1℃ | |

| Sealing method | Self-sealing, with temperature measurement hole and handheld thermometer | |

| Temperature measurement element | 3 sets of K-type thermocouples for more uniform temperature control (three-zone temperature control)

Provide the ability to set a thermal profile for each heating zone |

|

| Gas system configuration | Flow meter | 2-channel float flow meter (0.1-1.5L/min, 20-200ml/min,other flow range can be customized) |

| Pressure gauge | Mechanical vacuum pressure gauge | |

| Regulating valve | Manual regulating valve | |

| Pipeline connection method | Double-card sleeve PTFE tubing connection(φ6.35) | |

| Pressure range | -0.1-0.15Mpa (absolute pressure) | |

| Opening system | Transmission mode | Lever transmission |

| Motor | DC linear actuator motor | |

| Sensor type | Two sets of displacement sensors to prevent loss of control | |

| Vacuum system | Vacuum pump | Mechanical vacuum pump: Direct-drive rotary vane vacuum pump (two-stage rotary vane) |

| Pumping rate | 9.9(m³/H) | |

| Inlet/outlet connection | KF25(mm) | |

| Motor speed | 1440(rpm) | |

| Ambient Temperature | 5~40℃ | |

| Noise level (dB) | ≤56 | |

| Vacuum gauge | Digital vacuum gauge, capable of digitally displaying the pressure inside the furnace tube | |

| Vacuum level | 5-10Pa | |

| Pressure sensor | Displays positive pressure inside the tube and allows for setting of overpressure alarms | |

| Differential pressure sensor | Maintains a certain pressure difference inside the tube | |

| Control system | Control mode | Embedded operating system with graphical interface in both Chinese and English, 7-inch color touchscreen input, intelligent human-machine dialogue mode |

| Temperature curve setting | can store up to 15 temperature curves, each curve can be set with 30 segments of “time-temperature curve,” real-time monitoring, dynamically displaying the “time-temperature curve” | |

| Temperature calibration | Non-linear correction of the temperature difference between the temperature control temperature and the sample temperature throughout the system | |

| Equipment operation time recording | Sintering data storage, automatic report generation, real-time recording and retrieval | |

| System protection | Over-temperature alarm, over-current protection, open circuit prompt | |

| Others | Electrical specifications | Three-phase 380V, 50Hz, 8KW |

| Included accessories | 1 furnace tube, 1 set of sealing flanges, 1 set of quartz thermoblocks, 1 user manual, miscellaneous tools, etc. | |

Applications:

The 1200°C Three-Zone CVD Tube Furnace is ideal for a wide range of applications across various industries:

- Semiconductor Industry:

- Thin Film Deposition: Essential for the deposition of thin films in semiconductor device fabrication, including insulating, metallic, and alloy materials.

- Oxidation and Diffusion Processes: Used in the production of integrated circuits (ICs), transistors, and microelectromechanical systems (MEMS).

- Material Science & Research:

- Nanomaterial Synthesis: Used for synthesizing advanced nanomaterials such as carbon nanotubes, graphene, and quantum dots.

- Coating Technologies: For coating and modifying materials used in research and development, especially in high-performance applications like sensors, photovoltaics, and energy storage.

- Solar Energy:

- Photovoltaic Cells: Deposition of thin films for solar cells, ensuring high efficiency and durability under varying environmental conditions.

- Environmental Science:

- Catalysis and Environmental Research: Used for studying and developing catalytic materials and processes related to environmental protection, such as pollutant degradation and CO2 capture.

- Optics & Electronics:

- Optical Coatings: Thin film deposition for optics and display applications, including anti-reflective coatings, lenses, and mirrors.

- Electrical Contacts: For the deposition of conductive materials in electronic components, including electrodes and interconnects.

- Biomedical & Pharmaceutical:

- Coatings for Medical Devices: Deposition of biocompatible thin films for medical implants and devices to improve their performance and longevity.

- Energy Storage:

- Battery & Supercapacitor Materials: Deposition of electrode materials for lithium-ion batteries, supercapacitors, and other energy storage devices.

For More Options on CVD Furnace System

Please visit our website [CVD Furnace System Collection]

For More Information on CVD Furnace System

Please read our blog [CVD Furnace System]