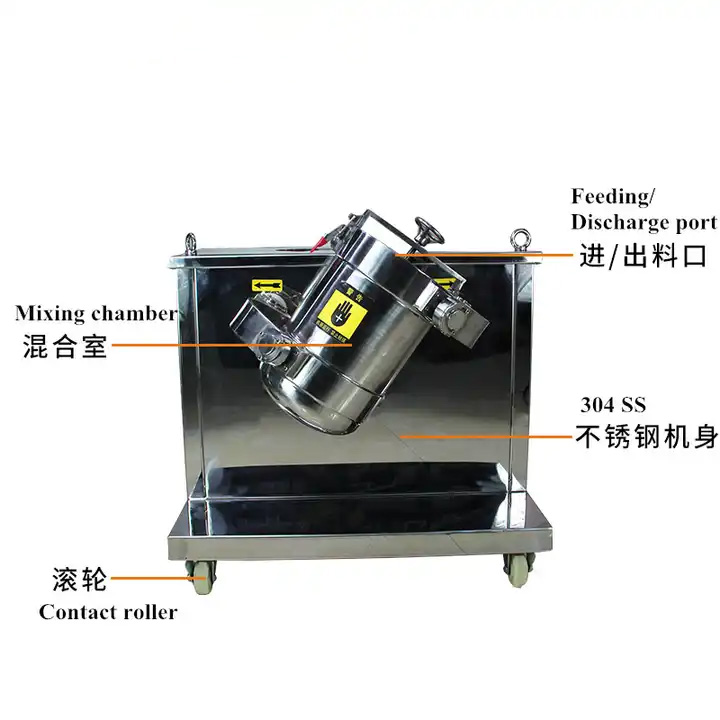

Three Dimensional Motion Mixer

Applications:

Three-Dimensional Motion Mixers are widely used in the efficient mixing of powdery and granular materials in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy, national defense industry and various scientific research units.

Introduction:

Three-Dimensional Motion Mixer is the charging cylinder driven by the main shaft, makes the compound motion such as translation, rotation and rolling, which urges the material to make three-way composite motion along the cylinder, so as to realize the mutual flow, diffusion, accumulation and doping of various materials, so as to achieve the purpose of uniform mixing.

The multi-direction movement of the mixing cylinder, no centrifugal force of the material, incomparable gravity segregation and stratification, accumulation phenomenon, mixing rate of more than 99%, is a more ideal product in various mixers.

Not only does the design of high-value design, structure and system improve efficiency and performance more effectively, the application of noise control patent technology brings more comfortable and safe use experience

Main Features:

- The loading capacity of the three-dimensional mixer drum is large, with a maximum reaching 80-90% (ordinary mixers typically range from 40-70%).

- The structure of the three-dimensional motion mixer drum is compact, making loading and unloading convenient and intuitive.

- High uniformity in material mixing, short mixing time, and low energy consumption – energy-efficient.

- The three-dimensional mixer is made of stainless steel, aesthetically pleasing, washable, facilitating easy cleaning during large-scale production.

- All parts of the three-dimensional mixer drum have smooth transitions with rounded arcs, undergoing precision polishing through multiple processes to achieve a dead-angle-free design. It is non-adhesive, easy to discharge, and easy to clean.

- Due to the multi-directional motion of the mixing drum, there is minimal centrifugal force acting on the material, preventing segregation, layering, and accumulation phenomena.

- Components with disparate weight ratios can achieve a mixing rate of over 99.9%, making it one of the most ideal products among mixer types.

- Smooth and reliable operation, minimal vibration, and convenient for operation and maintenance.

Specifications:

| Product Name | Lab Three-Dimensional Motion Mixer | ||

| Model | S-5L | S-10L | S-20L |

| Capacity | 5L | 10L | 20L |

| Available capacity | 50-70% of grinding tank | ||

| Optimal mixing capacity | Not less than 10% of grinding tank | ||

| Load Weight Limits | 20kg | ||

| Mixing time | 0-99H | ||

| Suitable for mixing materials | Powder | ||

| Time Range | 0-99H | ||

| Tube material | 304L | ||

| Thickness of barrel | 2mm | ||

| Thickness of seal plate | 1.5mm | ||

| Support internal motor plate | 10mm | ||

| Power | 1KW | ||

| power of motor | 0.75KW | ||

| Reduction box | WPDA-70 | ||

| Speed of main-shaft | 13 RPM | ||

| Electrical protection grade | 3 grade | ||

| self-aligning bearing | UCP-35 | ||

| Dimension | 800*800*800 | ||

| Distance of outlet from ground | 350 | ||

| Import and Export Dimensions | 110 | ||

| Driving mode | Gear reducer direct transmission | ||

| Weight | 120KG | 130KG | 145KG |