High Energy Dispersed Powder Uniform Mixing and Grinding Stirred Ball Mill

Introduction:

The stirred ball mill is equipped with an upright rotating agitator that drives the motion of the grinding media. During operation, the barrel remains stationary while the agitator plays a crucial role, allowing for sampling and adding grinding materials without stopping the machine. This equipment can disperse two or more different substances evenly, achieving uniform mixing while accelerating heat and mass transfer processes. It also features high-energy water cooling circulation, pollution-free operation, dispersion and homogenization, and grinding and mixing capabilities.

Features and Benefits:

- Variable Frequency Speed Control: The agitator rod speed can be freely adjusted to achieve different experimental effects.

- Replaceable Agitator Rods: The agitator rods can be freely replaced as consumables, allowing for experiments with various materials.

- Multiple Material Options: Agitator rods and barrels are available in zirconia, polyurethane, stainless steel, PTFE, and other materials, offering good compatibility and a wide range of applications.

- Intelligent Program Controller with Timing and Power Failure Memory: Equipped with a timing function and power failure grinding time memory.

- Adjustable Barrel: The barrel can be raised and lowered for easy operation.

- Cooling Fan: Equipped with a cooling fan for rapid air exchange and heat dissipation.

- High energy dispersed powder uniform mixing and grinding: Professional design fine grinding discharging granularity up to 0.1 um.

- Optional water cooling circulation reduce grinding temperature: Temperature sensitive materials can be grind normally.

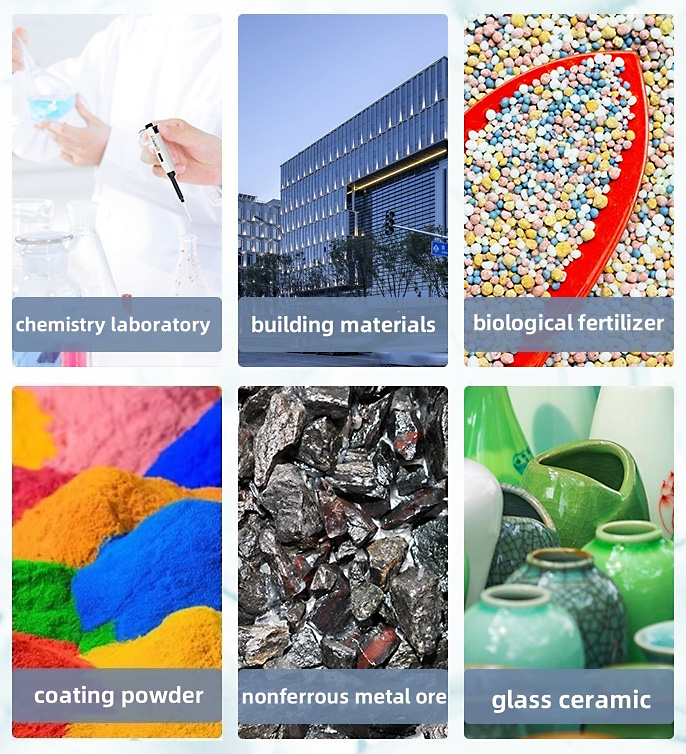

Applications:

The stirred ball mill is one of the main equipment for modern fine crushing. Due to its high energy density, fine product particle size, low environmental pollution, simple structure, and convenient maintenance, it is widely used in electronics, ceramics, polysilicon, lithium batteries, phosphors, rare earths, metallurgy, chemical, geology, and research laboratories for clean crushing.

The stirred ball mill can also be used for sample preparation in other industries, for crushing raw materials into fine or medium-sized particles, such as in electronics, ceramics, polysilicon, batteries, and various ores.

Dischaging granularity can reach 0.1um.

Technical Parameters of Stirred Ball Mill:

| Model | SM-2L | SM-3L | SM-5L | SM-8L | SM-10L |

| Power | 1.5KW | 3KW | |||

| Power Supply | 220V | 380V | |||

| Speed | 0-900 | 0-1000 | |||

| Cooling Device | Water Cooling Circulation | ||||

| Grinding Jar Volume | 2L | 3L | 5L | 8L | 10L |

| Charging Capacity | 660ml | 1000ml | 1600ml | 2800ml | 3600ml |