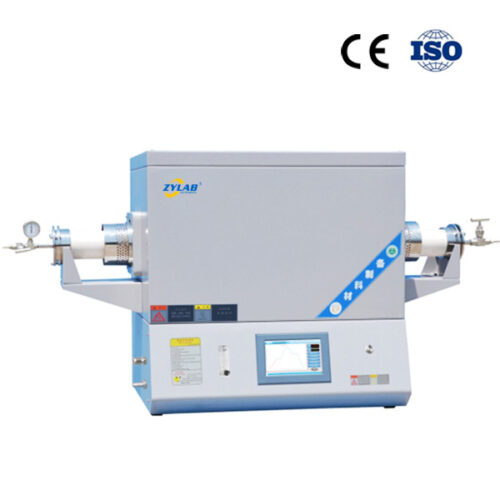

Dual-Furnace Sliding PECVD System for High-Precision Nanowire and Thin Film Deposition

Introduction

The Dual Furnace Sliding PECVD system features a dual-temperature zone tube furnace, incorporating a 500W RF generator, two movable independent sintering furnaces, a high-precision mass flow mixing system, and a stable anti-backlash vacuum system. It is designed for the growth of nanowires and the fabrication of various thin films using the CVD method.

Key Features

- One-Step Cleaning and Coating: Ensures no secondary contamination during the process.

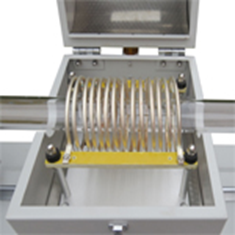

- Top-Opening Structure: Facilitates easy observation of the samples during the process.

- Fully Automatic Control: Touchscreen interface with digital display for easy operation.

- Fast Heating and Cooling: Achieved through the sliding furnace body for quick thermal response.

- Stable RF Power Supply: Ensures uniform temperature distribution, improving film quality.

Technical Parameters

| Model | PECVD-1200-50-2 |

| Power Supply | AC 220V, 3KW; RF Power: 300W or 500W, 13.56 MHz |

| Maximum Temperature | 1200°C (<1 hour) |

| Continuous Temperature | 1100°C (continuous operation) |

| Heating Rate | ≤20°C/min |

| Heating Zone Length | 200mm + 200mm (split design for maximum temperature gradient control) |

| Furnace Tube Dimensions | Φ50*1800mm |

| RF Coil | Multi-node, silver-plated, water-cooled copper coil for compatibility with various RF power supplies

|

| Control System | 1. Dynamic display of sintering curves and the ability to save and customize multiple process curves

2. Scheduled sintering for unattended operation 3. Real-time monitoring of sintering power and voltage, with data logging and export for paperless record-keeping 4. Remote control and real-time equipment status monitoring 5. Nonlinear temperature correction during the sintering process for both the furnace and sample

|

| Temperature Accuracy | ±1°C |

| Heating Element | Mo-doped Fe-Cr-Al alloy

|

| Sealing System | Come with Stainless Steel Sealing Flange. Vacuum level of 10Pa (mechanical pump)。

(Pressure Measurement and Monitoring:Using a digital vacuum gauge allows for a clear display of the equipment’s vacuum level, ensuring more accurate experimental data and results.) |

| Gas Supply System | Integrated mass flow controller |

| Net Weight | 100kg |

| Usage Precautions | 1. Do not open the furnace when the temperature exceeds 300°C to prevent injury.

2. The furnace tube pressure must not exceed 0.125MPa (absolute pressure) to avoid damage to the sealing flange. 3. When operating at high vacuum (10⁻³Pa), the temperature should not exceed 800°C. |

| Service Support | Includes a one-year limited warranty and lifetime support (excluding consumable parts like processing tubes and O-rings). Replacement parts can be ordered as needed. |

Applications

The Dual Furnace Sliding PECVD System is primarily used for:

- Nanowire Growth: Ideal for growing nanowires, which are crucial in applications like nanoelectronics, sensors, and advanced materials development.

- Thin Film Deposition: Used in Chemical Vapor Deposition (CVD) processes to create various thin films for semiconductor devices, solar cells, coatings, and other electronic components.

- Material Research and Development: Suitable for developing new materials and coatings in research environments, particularly in fields like nanotechnology, materials science, and electronics.

- Semiconductor Fabrication: Employed for depositing thin films used in the production of semiconductors, photovoltaic devices, and other microelectronics.

For More Options on PECVD System

Please visit our website [PECVD System Collection]