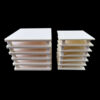

High Strength Refractory Silicon Carbide Kiln Shelves

Introduction:

A silicon carbide kiln shelf is a type of shelf or platform used inside a kiln for firing ceramics. It is made of silicon carbide, a highly durable and heat-resistant material. These shelves are placed inside the kiln to support and hold the ceramic ware during the firing process.

Silicon carbide kiln shelves are preferred for their ability to withstand high temperatures, resist warping and bending, and provide a smooth and stable surface for firing ceramics.

They are commonly used in pottery studios, ceramic workshops, and industrial kilns for firing pottery, ceramics, and other similar materials.

Classification:

Product Features:

1. Made of refractory silicon carbide.

2. High strength, hard, resistant to high temperatures, and will not deform with long-term use.

3. High density, smooth surface, no slagging during use, and not prone to cracking.

4. Excellent performance, able to adapt to firing in both oxidizing and reducing atmospheres for ceramics.

5. Wide firing temperature range, usable within the range of 800 to 1400°C.

Product Specifications:

| Square Shelf Dimensions | |||

| 170×240mm | 170×260mm | 180×180mm | 200×320mm |

| 250×360mm | 250×410mm | 260×260mm | 280×280mm |

| 280×340mm | 280×420mm | 300×300mm | 300×340mm |

| 300×400mm | 340×340mm | 350×400mm | 370×500mm |

| 370×550mm | 400×400mm | 450×450mm | 400×500mm |

| 480×500mm | 500×520mm | 500×550mm | 500×600mm |

| 550×600mm | 560×620mm | 640×640mm | |

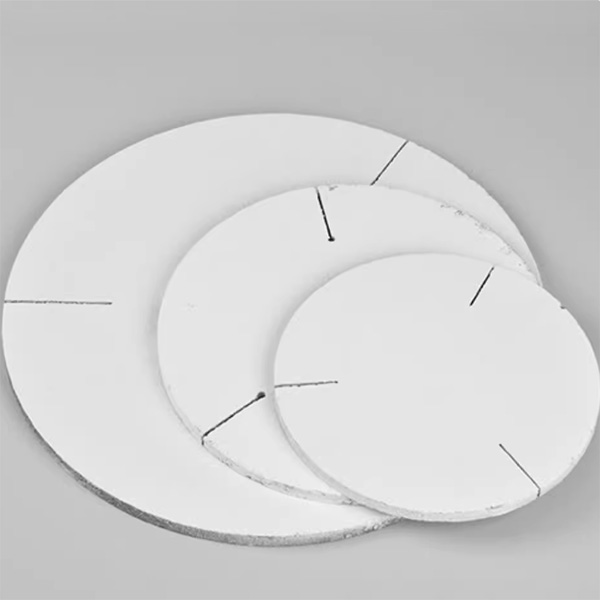

| Round Shelf Dimensions | |||

| φ200mm | φ250mm | φ280mm | φ350mm |

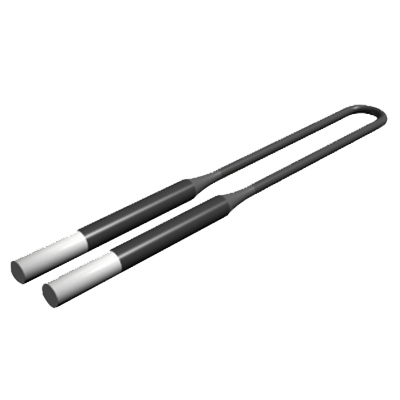

| Post Height | |||

| 50mm | 80mm | 100mm | 120mm |

| 160mm | 220mm | 240mm | 260mm |

| 280mm | 300mm | 350mm | 500mm |

| 580mm | 700mm | ||

| The shelf thickness ranges from 7mm to 18mm. For more sizes and detailed specifications, please consult our professional customer service staff. | |||

Instructions for Using Silicon Carbide Kiln Shelves:

1. Pour an appropriate amount of aluminum oxide powder onto the kiln shelf and spread it evenly with a brush to prevent sticking (new shelves come with a layer of white aluminum oxide powder).

2. Place items of the same height on one layer of kiln shelf.

3. Place support posts according to the height of the items, typically 3-4 posts are sufficient.

4. Place another kiln shelf on top, layer by layer, with taller items suitable for placement in the upper part of the kiln.

Precautions for Using Silicon Carbide Kiln Shelves:

1. Before loading the kiln, thoroughly wipe off the glaze on the bottom of ceramic vessels to prevent sticking.

2. If unsure about the flowability of the glaze, aluminum oxide wafers can be placed at the bottom of the artwork to prevent sticking.

3. When loading bisqueware, ensure that the weight distribution of stacked items is reasonable. Also, consider the shrinkage of clay during firing and arrange the artwork accordingly.

4. During glaze firing, avoid placing items too close together (a distance of about one finger-width apart is sufficient). This not only aids in heat circulation but also prevents problems on the surface of one item from affecting surrounding items.

5. Whether loading bisqueware or glazed items, do not overfill the kiln and ensure that the items do not come into contact with the heating elements (items should be at least two fingers away from the elements).

6. After each layer is loaded, clean the back of the kiln shelves to avoid dust contamination on the artwork. Also, ensure that the support posts remain in a vertical line to prevent shelf deformation and cracking.