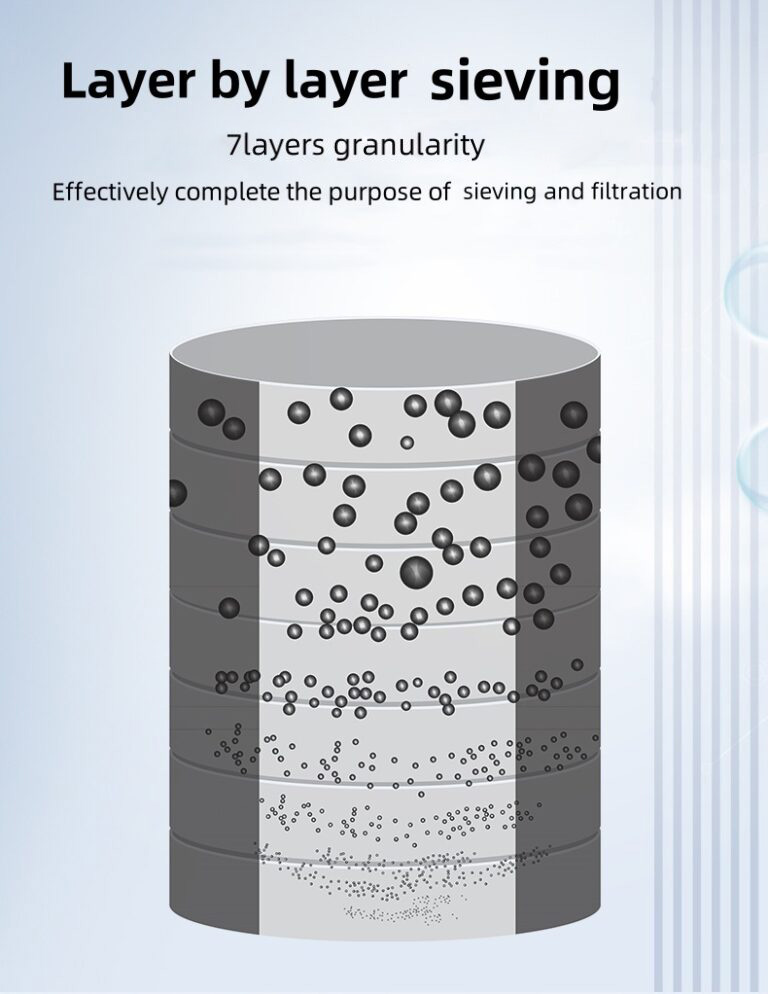

Laboratory 7 Layers Grading Accurate Sieving Sieve Shaker

Introduction:

Features and Benefits of Sieve Shaker:

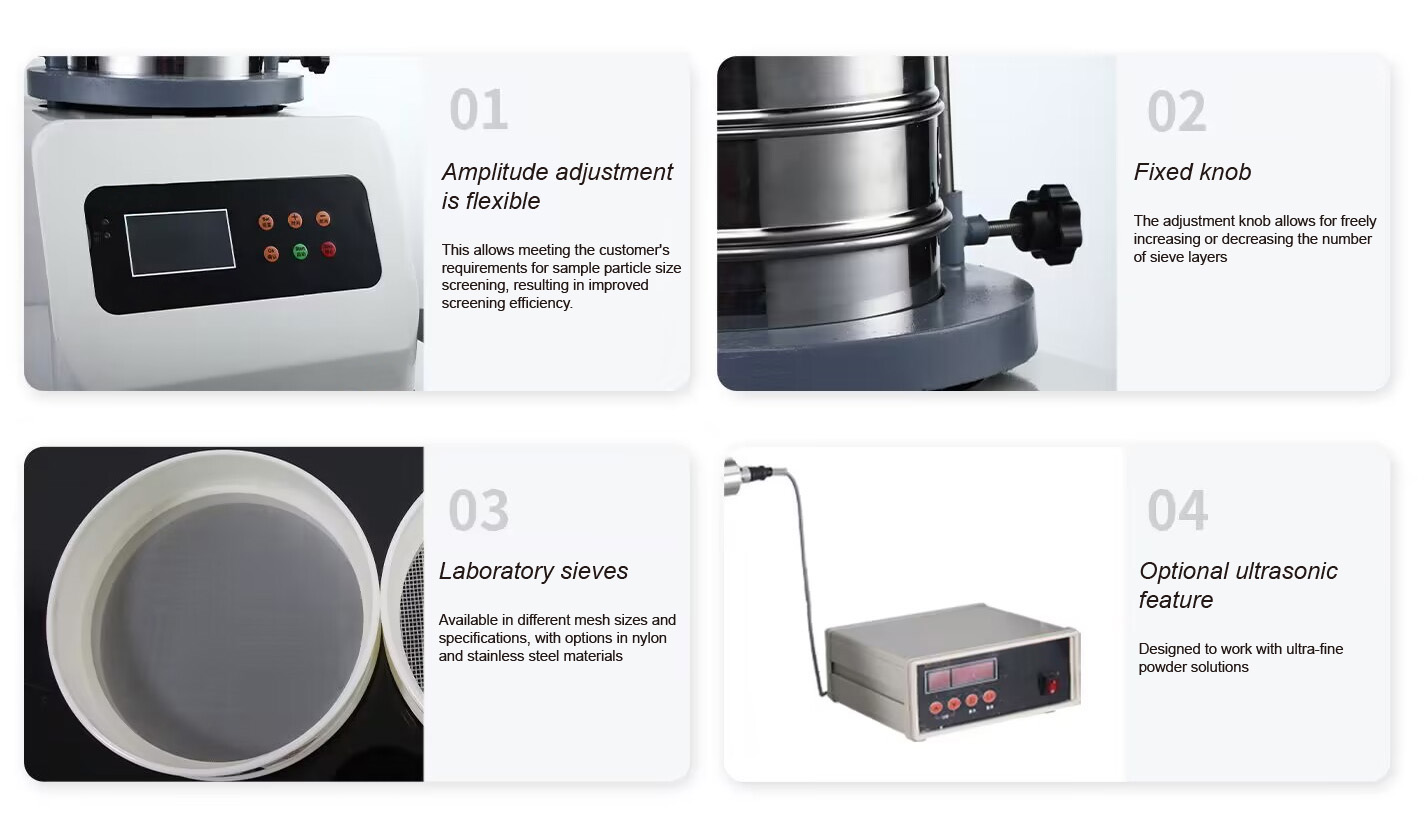

- High efficiency, sophisticated and durable design, suitable for sieving any powder or liquid.

- Compact size, space-saving, and easy to move.

- The sieve machine can accommodate up to eight test sieves (including the bottom sieve), allowing precise separation of a granular material into 2 to 7 particle segments at the same time.

- Automatic shut-off timer.

- Ensures experiment repeatability.

- Fully functional and easy to operate.

- Low noise and lightweight.

- Platform operation, no need for fixation.

- Optional ultrasonic feature, suitable for ultrafine powder solutions.

- Sieve mesh material options include stainless steel and nylon.

Technical Parameters of Sieve Shaker:

| Model | S-200 |

| Sieve diameter | 200mm |

| Measuring range | 0.025~3mm |

| Motor power | 0.125kw |

| Sound | Less than50 dB |

| Amplitude | 0~3mm |

| Speed | 1420rpm |

| Overall dimension | 400*300*300mm |

| Net Weight | 30Kg |

| Power suppy | 220V 50HZ |

Other Optional Models:

| Model | S-200 | S-300 | S-400 | S-600 |

| Sieve Diameter | 200mm | 300mm | 400mm | 600mm |

| Number of Sieve Layers | 7 Layers | 3 Layers | ||

| Sieve Material | Nylon/Metal | Metal | ||

| Sieve Selection Range | 5-1000mesh | |||

| Power | 0.125kw | 0.125kw | 0.25kw | 0.37kw |

| Power Supply | 220V 50HZ | 380V 50HZ | ||

Applications:

Sieve shakers are versatile laboratory tools used across various industries for particle size analysis, grading, and separation. Here are some common applications:

-

Pharmaceutical Industry:

- Powder Screening: To ensure consistent particle size distribution in drug formulations, which affects drug release and absorption.

- Quality Control: Checking the granularity of excipients and active pharmaceutical ingredients (APIs).

-

Chemical Industry:

- Powder and Granule Grading: Used to grade chemicals into different particle sizes for specific applications, ensuring uniformity in product batches.

- Catalyst Screening: To ensure catalysts have the correct particle size for optimal reaction rates.

-

Food Industry:

- Flour and Powder Screening: To ensure uniform particle size in products like flour, spices, and baking powders.

- Quality Assurance: Ensuring consistency in products like sugar, salt, and other granulated food products.

-

Construction Industry:

- Aggregate Testing: Grading sand, gravel, and crushed stone for concrete and asphalt production.

- Cement and Lime: To ensure proper particle size distribution for better mixing and bonding.

-

Mining and Metallurgy:

- Ore and Mineral Screening: Used to classify ores, minerals, and coal according to particle size.

- Quality Control: Ensuring the consistency of raw materials for processing.

-

Environmental Science:

- Soil Analysis: Determining soil particle size distribution for agricultural and environmental studies.

- Waste Management: Grading waste materials for recycling and processing.

-

Cosmetics Industry:

- Powder Grading: To achieve consistent particle size in products like makeup powders and creams.

- Quality Control: Ensuring uniformity in raw materials and final products.

-

Ceramics and Glass:

- Material Sizing: For precise sizing of raw materials used in ceramics and glass production.

- Consistency Testing: Ensuring the homogeneity of particle sizes for better product quality.

-

Nanotechnology:

- Particle Size Analysis: For research and development of nanoparticles, ensuring precise size distribution in innovative materials.

-

Academic and Research Laboratories:

- Research and Development: Used in various experiments to analyze particle sizes and distributions in different materials.

- Teaching Tool: Helps students understand the principles of particle size analysis and material separation.

These applications highlight the importance of sieve shakers in ensuring product quality, consistency, and compliance with industry standards.

For More Information on Sieve Shaker

Please read our article [Sieve Shaker]

For More Sample Preparation Solutions

Please visit our website [Sample Preparation]