Lab Hydraulic Crimping Press Sealing Machine for Coin Cell

Introduction:

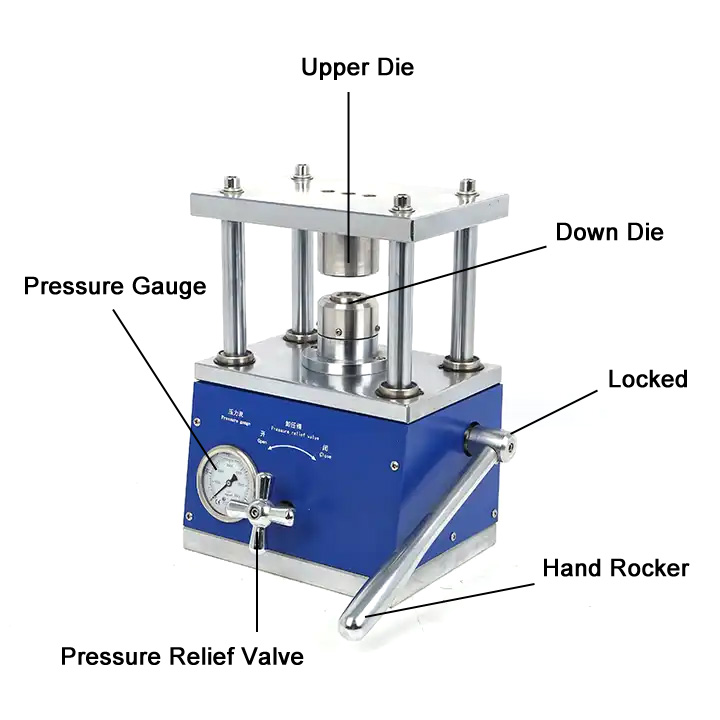

This sealing machine for coin cell is primarily used for the sample preparation in the research and development of laboratory battery materials. It is employed for sealing research in batteries and capacitors, and can also be used for small-scale trial production in factories. With different molds, it can be utilized for tasks such as battery disassembly and picking research, electrode pressing, and battery powder pressing.

Key Features and Benefits:

1.Specially designed hydraulic structure for effortless operation, simple and reliable structure.

2.Built-in pressure gauge for observing and accurately controlling the sealing pressure.

3.Equipped with a safety valve to adjust pressure as needed, and it allows setting a pressure limit to prevent damage due to excessive pressure from accidental operations.

4.Precision mold design with limited positioning to prevent jamming.

5.Sturdy steel structure design for stable and safe operation.

6.Compact size, convenient operation, suitable for operation within a glovebox.

Key Parameters:

Model: CCM-20

Maximum Pressure: 1.2T (approximately 150Mpa/cm²)

Handle Pressure: <6kg

Die Closing Distance: 20mm

Applicable Battery: CR20/16/24/30, etc.

Dimensions: 223*170*325mm

Weight: Approximately 25kg

Applications:

The lab hydraulic crimping press sealing machine for coin cell batteries has various applications in laboratory research and small-scale production. Some key applications include:

- Battery Material Research: Used in laboratories for researching and developing new battery materials, particularly in the preparation of coin cell samples for testing.

- Coin Cell Assembly: Essential for assembling coin cells used in various applications, including electronics, medical devices, and portable gadgets.

- Battery Sealing: Specifically designed for sealing coin cells with precision, ensuring a secure and reliable enclosure for the battery components.

- Electrode Pressing: Capable of pressing electrodes in coin cells, contributing to the overall manufacturing process of batteries.

- Sample Preparation: Facilitates the preparation of coin cell samples for testing and analysis in material science and electrochemistry studies.

- Battery Research and Development: Supports R&D activities focused on improving battery performance, efficiency, and exploring new technologies.

- Small-scale Production: Suitable for small-scale production in factories, enabling the production of coin cells for initial testing and evaluation.

- Academic Research: Widely used in academic research institutions for conducting experiments related to battery technology and energy storage.

- Quality Control: Plays a crucial role in maintaining quality control standards for coin cell batteries during the manufacturing process.

- Materials Testing: Used to test the properties and characteristics of various battery materials, ensuring reliability and efficiency in battery performance.