Production Type Vacuum Atmosphere Vibrating Rotary Sintering Furnace 1200.C

Introduction:

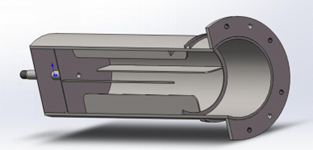

This vibrating rotary sintering furnace 1200.C is a highly automated powder heat treatment equipment, which used for the preparation of materials in various applications such as lithium battery positive and negative electrode materials, rare earth materials, chemical catalysts, magnetic materials, and powder hydrogen reduction. The equipment is capable of tilting and continuous rotation, utilizing a high-purity quartz tube with an embedded lifting scraper structure to ensure uniform heating of materials and guarantee sintering effectiveness.

Features of Rotary Sintering Furnace 1200.C:

1.Under the rotary oscillation of the material in the reaction chamber, both radial and axial tumbling occur, ensuring uniform heating of the material and thorough contact with the gas. This prevents issues such as over-sintering and incomplete sintering caused by static sintering.

2.Utilizes high-purity Al2O3 fiber refractory insulation material for superior insulation performance, reducing equipment power consumption.

3.Incorporates an advanced dynamic sealing device to ensure the equipment can operate in vacuum and atmospheric conditions.

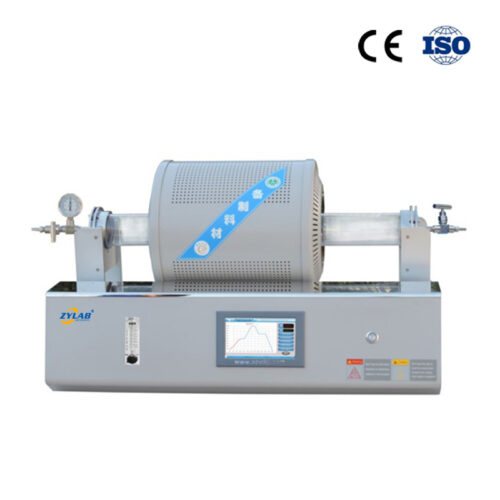

4.Operates with a fully automatic control system, featuring a 7-inch touchscreen for real-time tracking and display of equipment status.

5.The furnace body can be tilted between -5 and 30 degrees, facilitating easy loading and unloading operations for the user.

Technical Parameters:

| Model | RT1200-200T2 or RT1200-200T3

|

||||

| Power supply | AC380V 12KW or AC380V 18KW | ||||

| Max temperature | 1200.C(<1 hour) | ||||

| Working temperature | 1100.C(continuing) | ||||

| Heating rate | ≤20.C/min | ||||

| Heating length | 600mm(300*2) or 900mm(300*3) | ||||

| Tube size | Dia 200* 1200mm

|

||||

| Temperature accuracy | +/- 1 ℃ | ||||

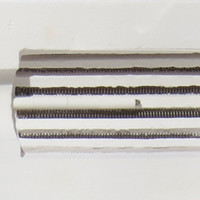

| Heating element |

Molybdenum-Doped Fe-Cr-Al Alloy High-Temperature Heating Wire |

|

|||

| Intelligent Touch Screen Control System | 1.Capable of storing 15 temperature profiles, avoiding the inconvenience of repetitive setup for different experimental processes.

2.The experimental process is more intuitive, and the operation is more convenient. 3.The embedded operating system features a bilingual graphical interface (English and Chinese), a 7-inch full-color touchscreen input, an intelligent human-machine dialogue mode, and non-linear sample temperature correction. 4.Equipped with functions such as over-temperature alarm, thermocouple disconnection alert, and leakage protection. |

|

|||

| Sealing System |  |

||||

| Vacuum level:≤10Pa(Mechanical Pump) | |||||

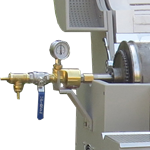

| Pressure Measurement and Monitoring |  |

Utilizing a mechanical pressure gauge with shock-absorbing oil to introduce damping effects during pressure fluctuations, reducing the back-and-forth oscillation of the pointer. | |||

| Gas control |  |

Gas flow rate is controlled using a float flowmeter, integrated seamlessly with the equipment, and subjected to leakage testing before leaving the factory. | |||

| Dimension | 1300(L) * 700(W) * 1500(H)mm |  |

|||

| Weight | 120KG | ||||

| Warranty | One-year warranty, lifetime support (excluding consumable parts such as furnace tube, O-rings ) | ||||

Applications:

This vibrating rotary sintering furnace is a highly automated powder heat treatment equipment, which used for the preparation of materials in various applications such as lithium battery positive and negative electrode materials, rare earth materials, chemical catalysts, magnetic materials, and powder hydrogen reduction.