Vacuum Atmosphere Vibrating Rotary Sintering Furnace

Applications:

The vacuum atmosphere vibrating rotary sintering furnace is designed for:

Laboratory calcination, drying, high-temperature reactions, heat treatment, and carbonization of powdered or granular materials.

Including but not limited to positive and negative electrode materials for lithium-ion batteries (such as iron aluminum phosphate, lithium manganese oxide, lithium cobalt oxide, ternary materials, graphite anodes, etc.), rare earth materials, chemical catalytic materials, magnetic materials, powder metallurgy materials, non-ferrous metal materials, and non-metallic mineral materials like kaolin.

Users can also customize the atmospheric conditions based on the material sintering process.

Main Features:

- Double-layer steel structure.

- High-purity Al2O3 fiber refractory insulation material for maximum energy savings.

- High-purity alumina coating on refractory ceramics to extend service life.

- Specifically designed for powder or granule sintering, with dynamic movement of materials in the furnace tube for uniform heating and complete material reaction.

- Excellent dynamic sealing system to maintain atmospheric conditions during rotation.

- High heating efficiency with increased heated surface area due to material movement.

- Comprehensive systems including vacuum, power supply, gas flow, heating, motion, process control, system monitoring, and data acquisition.

Technical Parameters:

| Model | RT1200-50TIF | |||||

| Power supply | AC220V 1.5KW | |||||

| Max. temperature | 1200 ℃(<1 hour) | |||||

| Working temperature | 1150 ℃ (continuing) | |||||

| Heating rate | ≤ 20 ℃/min | |||||

| Length of heating zone | 200mm | |||||

| Effective Volume | 55ml | |||||

| Intelligent Touch Screen

Temperature controller |

• Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation.

•30 programmable segments for precise control. •Can store sintering programs to avoid the trouble caused by repeated settings of different processes. •Built in protection for over-heated and broken thermal couple, and leakage. |

|||||

| Temperature accuracy | +/- 1 ℃ | |||||

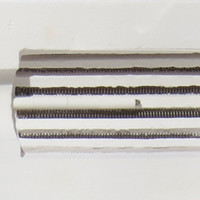

| Heating element |

Molybdenum-Doped Fe-Cr-Al Alloy High-Temperature Heating Wire |

|||||

| Sealing System |

|

|

||||

| Vacuum level:≤10Pa(Mechanical Pump) | ||||||

| Pressure Measurement and Monitoring |

Utilizing a mechanical pressure gauge with shock-absorbing oil to introduce damping effects during pressure fluctuations, reducing the back-and-forth oscillation of the pointer. |

|||||

| Dimension | 740(L) * 480(W) * 480(H)mm

|

|||||

| Net weight | 30KG | |||||

| Warranty | One-year warranty, lifetime support (excluding consumable parts such as furnace tubes, O-rings ) | |||||