Roller Jar Mill

Introduction:

The roller jar mill, also known as a rolling shaft ball mill, operates on the principle of a main shaft connecting to a motor, with a belt pulley and bearings for transmission. The relative movement between the main shaft and the jar’s surface generates friction, driving another passive shaft to achieve rolling. This type of machine differs from planetary ball mills or other crushing-type ball mills in the market. Its major advantage lies not in ultrafine grinding but in dry powder mixing, slurry mixing, and nano-mixing. Among all machine types, the mixing effect of the roller jar mill far surpasses that of other ball milling equipment. In the analysis of experimental data, it exhibits a narrower powder curve with a higher peak. As a result, materials can demonstrate greater stability in the subsequent processes.

Main Applications:

Dry Powder Mixing, Slurry Mixing, Nano-mixing.

The small jar mill is suitable for laboratory and small batch production. Because of it flexible and convenient operation, also used for production of some small enterprise.

Fields:

Widely used in electronic materials, ceramics, coatings, glass powder, fluorescent materials, non-metallic minerals, explosives, medicine, magnetic materials, equipment batteries, biological cultivation, food packaging, battery materials and other materials in the process of grinding and mixed.

Main Features:

- This machine is equipped with variable frequency speed control, featuring program control, and stepless speed adjustment.

- The roller axis distance is adjusted by a handwheel to prevent horizontal movement of the jar.

- The entire roller axis is lined with wear-resistant polyurethane, increasing the friction coefficient and preventing deformation of the jar due to slipping.

- The feed particle size is less than 3mm, with soil allowance up to 10mm. The discharge particle size is above 200-300 mesh (65-75 um).

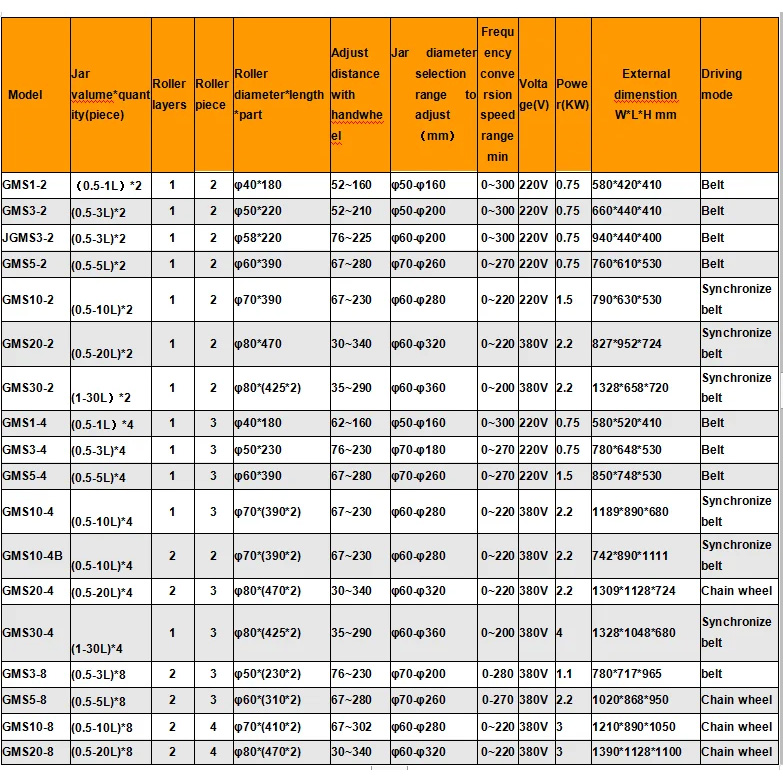

Specifications:

Optional Configure:

Grinding jar selection:

Nylon, Stainless steel, Polyurethane, PTFE, Alumina/corundum, Ceramics, PP polypropylene, Zirconium, Agate, Tungsten carbide

This series can place 1-8 different jars, can be selected between 1l / 3l / 5l / 10l / 10 l / 20l / 30l, suitable for multi-sample experiment or production enterprises.

Grinding balls selection:

Agate ball, zirconium ball, stainless steel ball, polyurethane ball, alumina ball, tungsten carbide ball, PTFE ball, silicon carbide ball, silicon nitride ball, etc.