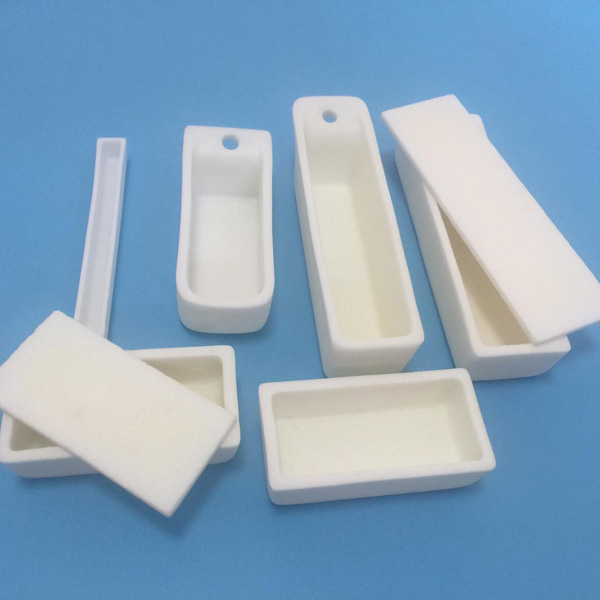

Rectangular Crucibles with Cover, 99% High Purity Alumina

Introduction:

Rectangular crucibles are typically square or rectangular in shape, made of alumina (Al2O3) material, with extremely high resistance to high temperatures, corrosion, and wear.

Its top is equipped with a lid or cover, which can seal the crucible to prevent material loss or entry of external impurities, while also helping to control the atmosphere or temperature of reactions.

This type of crucible is commonly used for samples requiring prolonged high-temperature treatment, such as melting experiments, ceramic production, heat treatment, and other high-temperature testing and processing processes.

Covers are available for purchase separately.

Alumina Purity: Al2O3 >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

Custom services such as slotting and drilling are available.

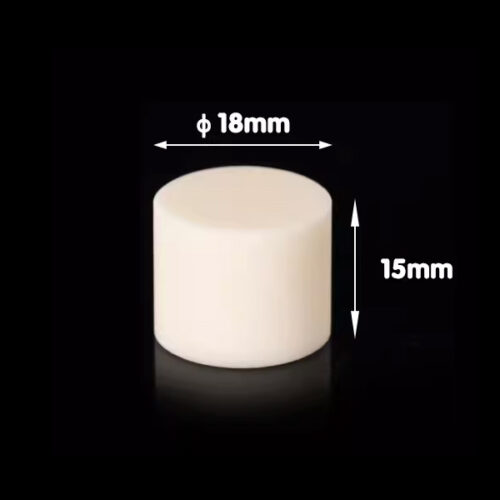

In addition to rectangular crucibles, we also offer arc-shaped crucibles, crucible boat, and cylindrical crucibles, which can be used in various high-temperature processing furnaces such as tube furnaces, muffle furnaces, and crucible furnaces.

Standard Products and Specifications:

| Rectangular Crucibles with Cover Specification (UoM:mm) | |||

| 20×20×10 | 20×20×17 | 25×25×15 | 30×20×10 |

| 30×20×17 | 30×30×10 | 30×30×20 | 30×30×30 |

| 40×30×20 | 40×30×25 | 40×30×30 | 45×8×6 |

| 45×22×13 | 50×10×10 | 50×20×10 | 50×20×15 |

| 50×20×20 | 50×25×10 | 50×25×20 | 50×25×35 |

| 50×40×10 | 50×40×15 | 50×40×20 | 50×50×10 |

| 50×50×20 | 50×50×25 | 50×50×30 | 60×30×10 |

| 60×30×14 | 60×30×15 | 60×30×20 | 60×30×30 |

| 60×40×20 | 60×60×25 | 65×65×25 | 65×65×30 |

| 65×65×35 | 65×65×65 | 70×70×30 | 75×75×15 |

| 78×38×22 | 80×40×20 | 80×40×30 | 80×40×30 |

| 80×40×40 | 80×40×55 | 80×40×40 | 80×40×55 |

| 80×80×40 | 85×85×40 | 90×60×20 | 90×60×30 |

| 90×60×40 | 90×60×45 | 90×90×30 | 90×90×45 |

| 100×20×20 | 100×30×10 | 100×30×15 | 100×30×20 |

| 100×30×30 | 100×40×15 | 100×40×20 | 100×50×30 |

| 100×60×40 | 100×60×60 | 100×100×25 | 100×100×35 |

| 100×100×40 | 100×100×60 | 100×100×100 | 105×105×12 |

| 105×105×40 | 115×65×45 | 115×115×35 | 120×60×20 |

| 120×60×40 | 120×80×30 | 120×80×40 | 120×120×50 |

| 120×120×100 | 135×135×60 | 140×140×38 | 140×140×45 |

| 140×140×70 | 150×150×30 | 150×150×50 | 150×150×60 |

| 150×150×80 | 155×120×50 | 160×120×35 | 160×120×85 |

| 160×140×120 | 160×160×45 | 180×180×60 | 200×100×25 |

| 200×100×50 | 200×150×200 | 200×200×50 | 200×200×80 |

| 200×200×100 | 225×225×83 | 250×150×80 | 250×250×80 |

| 250×250×100 | 300×60×60 | 300×180×70 | 300×200×80 |

| 330×330×80 | 330×330×120 | 330×330×160 | |

The above crucible dimensions are standard sizes; other sizes can be customized upon request.If you need more detailed information, please contact us immediately. We offer free quotes on all products!

Applications of Rectangular Crucibles:

High-temperature melting and sintering: Suitable for high-temperature melting and sintering of materials such as metals and ceramics.

Sample heat treatment: Includes processes such as annealing, calcination, and thermal analysis. The ark-shaped design facilitates the placement and removal of samples.

Ceramic production: Widely used in firing ceramic samples.

Molten metal analysis: Often used for melting samples for chemical analysis.

High-temperature storage and transportation: Can also be used for sample storage and transportation under high-temperature conditions.

Alumina Crucible Usage Precautions:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.