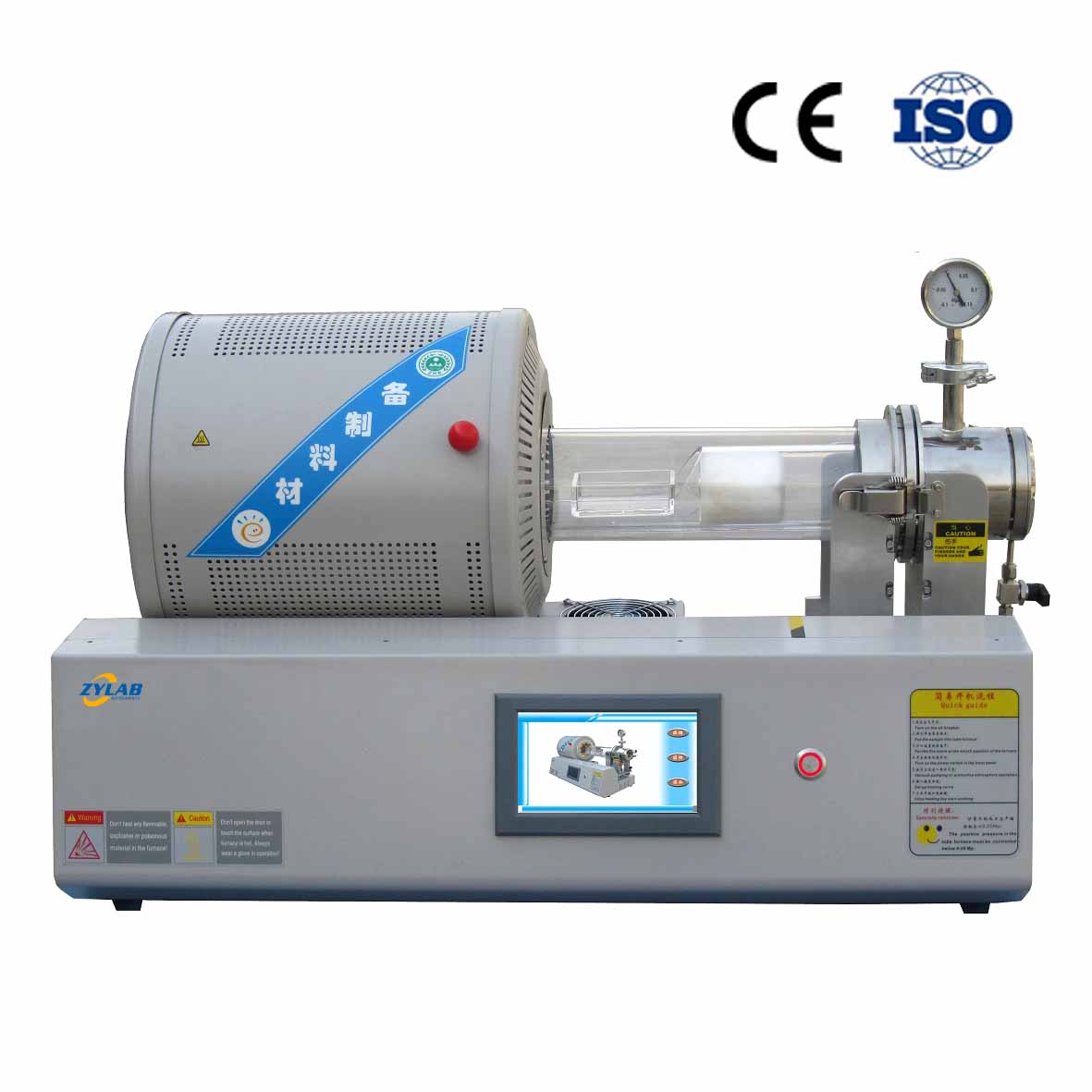

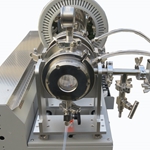

Rapid Thermal Processing Furnace

Introduction:

Rapid Thermal Processing Furnace is referred to as RTP furnace, which not only has a very fast heating rate, but also can directly move the sample to room temperature after the sintering process is completed to achieve rapid cooling in the physical state.

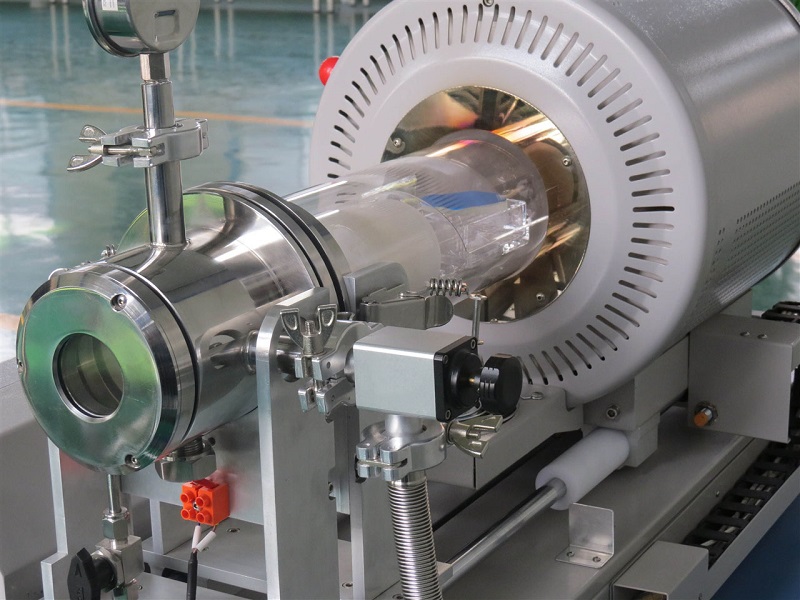

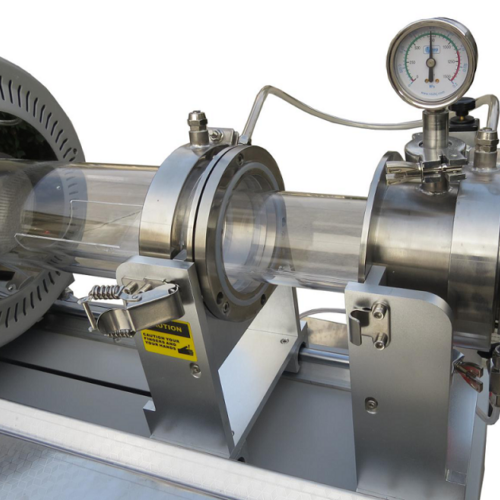

The equipment adopts the gas path structure of the inner tube inlet and the outer tube outlet, so that the reaction atmosphere can fully and evenly contact the processed samples.

It is a common equipment for growing large-size two-dimensional graphene by CVD method. The temperature measuring element is in direct contact with the sample to ensure the accuracy of the sample temperature.

Characteristics:

1. Double layer steel structure.

2. Max speed of temperature rising up to 100.C/S.

3. Double layer tube structure, the sample exposes in the atmosphere much more Constantly.

4.Measure the temperature of the sample surface directly, more accuracy.

5.The chamber can move from one side to another side according to users’ preset, this will meet more lab applications.

6.Rich expansion interface, to meet the needs of various types of tests.

7. High-purity Al2O3 fiber refractory insulation material saves energy to the greatest extent.

Technical Parameters:

| Model | HR1100-110IT

|

| Power supply | 380V, 15KW |

| Rated temperature | 1100.C (For long-term use, an external water cooling device must be connected) |

| Continue temperature | 100-1000.C (Continuous use must be connected to an external water cooling device) |

| Heating rate | Suggested ≤ 100.C/S |

| Temperature accuracy | +/- 1.C |

| Thermocouple | S type single platinum rhodium |

| Heating element | Infrared tube heating

|

| Length of heating zone | 200mm |

| Constant temperature zone | 100mm |

| Tube material | High purity quartz |

| Tube size | D110*L380mm |

| Control system |

|

| Presetting curve | 15 presetting curve |

| Protection setting | Over temperature alarm, over current protection, broken thermocouple protection |

| Sealing system | Stainless steel vacuum flange

Vacuum level ≤5Pa (mechanical pump) |

| Pressure Measurement and Monitoring | By employing a digital vacuum gauge, the vacuum level inside the furnace tube can be displayed more intuitively, ensuring a more accurate representation of experimental results.

|

| Expansion port | Vacuum measurement and FFC gas supply |

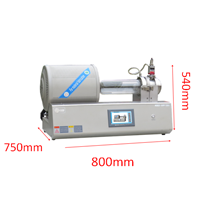

| Dimension | 800(L) * 750(W) * 540(H)mm

|

| Weight | 90KGS |

| Warranty | One-year warranty, lifetime support (excluding consumable parts such as furnace tubes, O-rings ) |

| Certificate | CE, ISO9001 |

Applications:

RTA(Rapid Thermal Annealing);

Graphene and other vapor deposition, epitaxial growth of carbon nanotubes, etc.

RTO; RTN (Rapid Thermal Oxidation/Rapid Thermal Nitridation);

RTP Annealing for Semiconductor Industry;

Silicidation;

Diffusion;

Implant Annealing;

Contact Alloying;

Crystallization and Densification.