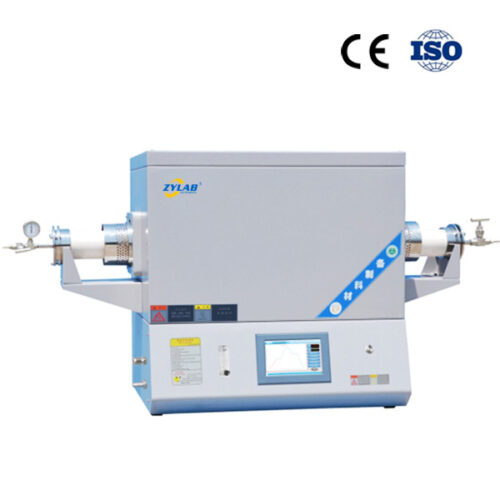

Dual Temperature Zone Rapid Annealing Slide Furnace

Introduction:

The furnace of this dual-temperature rapid annealing slide rail furnace can automatically move left and right according to the set requirements. The moving speed can be manually adjusted and the temperature field can be changed at any time. The furnace chamber on one side moves directly to the sample placement area after reaching the set temperature, thereby achieving rapid heating. The speed can reach 140℃/min. After sintering, the furnace chamber moves away from the sample placement area, thereby achieving rapid cooling of the sample. The cooling rate can reach 200~50℃/min from 1200℃ to 300℃.

Main Features of Rapid Annealing Furnace:

- Double-layer steel structure;

- High-purity Al2O3 fiber refractory insulation material for maximum energy saving;

- High-purity alumina coating on refractory ceramics to extend service life;

- Alumina tube plugs can help you establish custom temperature gradients within the tubes.

Technical Parameters:

| Model | CMT1200-100IIT |

| Power supply | AC240-400V 50/60Hz 8KW |

| Max.temp | 1200 ℃(<1hour) |

| Working temp | 1100 ℃ (Continuing) |

| Heating rate | ≤ 20 ℃/min |

| Heating length | 400 mm *2 |

| Tube size | Φ100*2000mm(optional:Φ80*2000mm) |

| Control system |

1.Can store up to 15 temperature profiles in advance, avoiding the hassle of repetitive setup for different experimental processes. |

| Temp accuracy | +/- 1 ℃ |

| Heating element |

Mo-doped Fe-Cr-Al alloy |

| Sealing system | Stainless steel vacuum sealing flange

|

| Vacuum | ≤10Pa (mechanical pump) |

| Pressure measurement and monitoring | Use a mechanical pressure gauge with shock-absorbing oil to prevent damage to the pressure gauge pointer. |

| Gas system | It is controlled by a float flowmeter and is integrated with the equipment for easy control. Air leakage testing has been carried out before leaving the factory. |

| Net weight | 400KG |

| Service Support | 1-year warranty with lifetime support (consumable parts such as furnace tubes and O-rings are not covered under warranty). |

Applications:

The dual temperature rapid annealing slide furnace finds applications in various industries and research fields where precise control over temperature profiles and rapid thermal processing are essential. Some of its applications include:

- Material Science Research: Used for annealing, sintering, and heat treatment of materials such as metals, ceramics, and composites. It allows researchers to study the effects of different thermal treatments on material properties.

- Semiconductor Manufacturing: Employed in the fabrication of semiconductor devices where precise thermal processing is crucial for doping, diffusion, oxidation, and other processes involved in semiconductor production.

- Thin Film Deposition: Utilized for annealing thin films deposited on substrates to improve film quality, crystallinity, and adhesion.

- Photovoltaics: Applied in the production of solar cells and modules for annealing and crystallization of semiconductor materials like silicon.

- Microelectronics: Used for the manufacturing of microelectronic devices such as integrated circuits (ICs), where controlled heating and cooling processes are necessary for device fabrication.

- Research and Development: Supports R&D activities in various fields including materials science, chemistry, physics, and engineering by providing a versatile platform for thermal processing experiments.

- Optoelectronics: Applied in the fabrication of optoelectronic devices such as LEDs, lasers, and photodetectors, where precise control of thermal processing parameters is critical for device performance.

- Nanotechnology: Utilized for annealing and processing nanomaterials and nanostructures, enabling the fabrication of nanoscale devices and exploring their unique properties.

- Biomedical Applications: Used in the sterilization of medical instruments and devices, as well as in research related to biomaterials and tissue engineering.

- Heat Treatment: Employed in various industrial sectors for heat treatment processes such as tempering, aging, and stress relieving of metallic components.