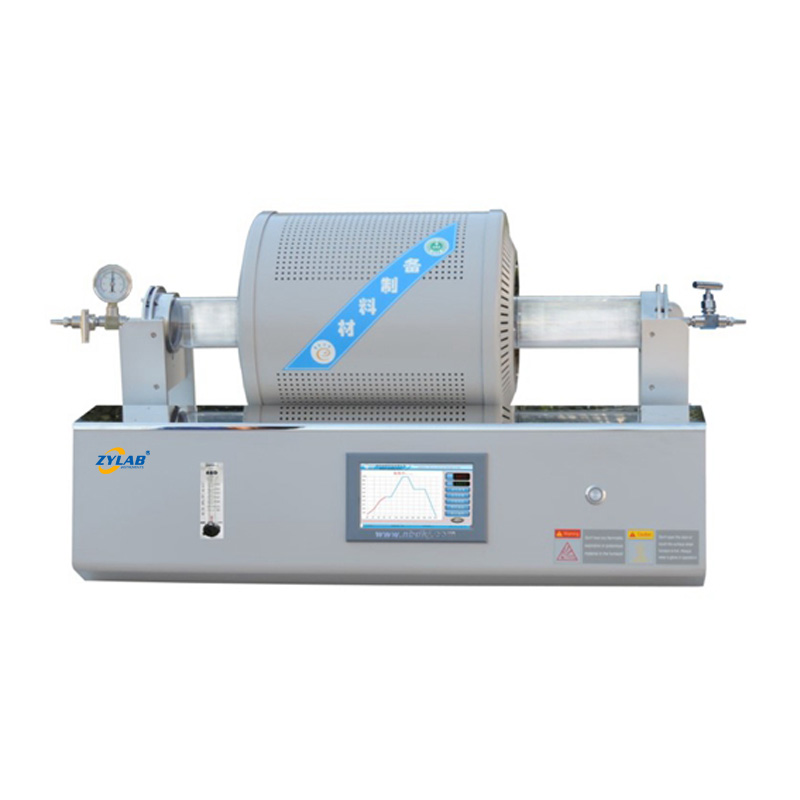

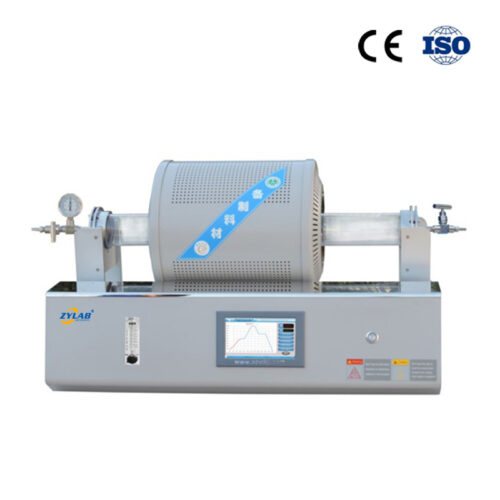

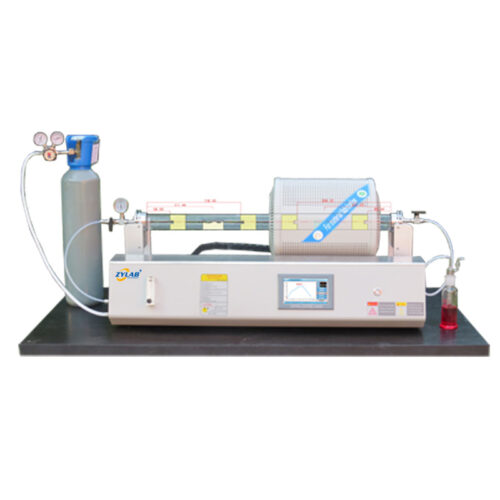

Rail Sliding Tube Furnace

Introduction:

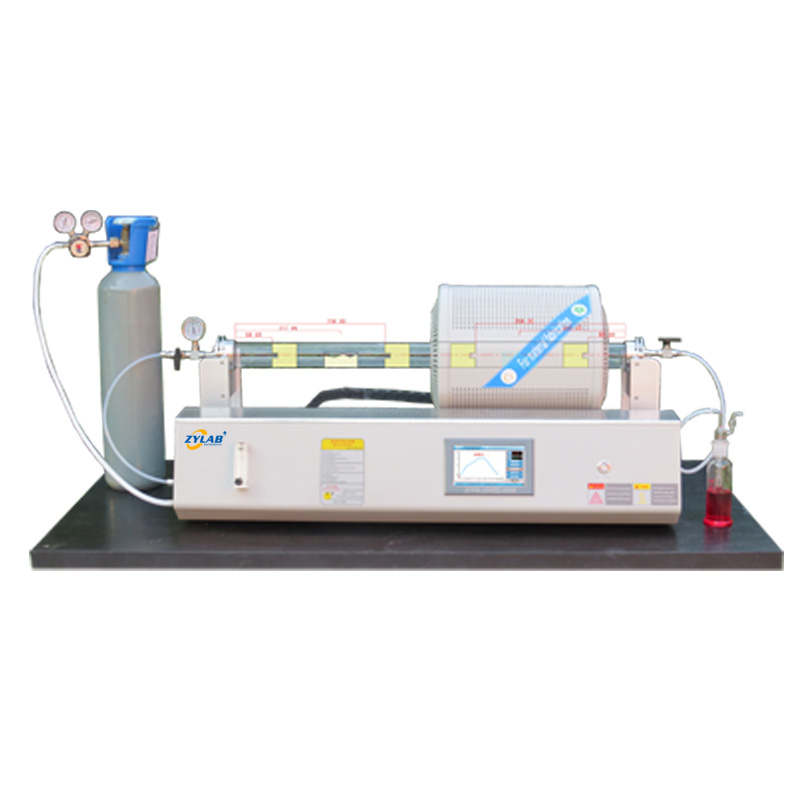

The chamber of this Rail Sliding Tube Furnace can be moved around automatically according to the set requirements. The moving speed can be adjusted manually, and the temperature field can be changed and the temperature can be lowered rapidly at any time. After heating up to the set temperature on one side of the furnace, the furnace chamber can be directly moved to the sample placement area on the other side, so as to achieve rapid heating, up to a speed of 140.C/min. After sintering, the furnace chamber can be removed from the sample placement area, so as to achieve rapid cooling of the sample. The cooling rate of 300.C~1200.C can reach 200.C ~ 50.C/min.

Main Features:

1. High purity quartz tube as furnace tube, Max. Temperature 1200.C(<1hour), continue working temperature Rt –1100.C.

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and auto control.

4. High purity alumina inorganic refractory, overall vacuum molding chamber, energy saving and ensure uniformity of temperature zone and a fast heating rate.

5. By using special lining import from Japan and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

6. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

7. Ring heating, able to meet rapid sintering of small sample. And the alumina tube plug helps you create custom temperature gradients in the tube.

8. With one channel gas flowmeter, atmosphere sintering more convenient.

9. Unique flange has a multi-function test holes, insert the corresponding electrode to test tube temperature or atmosphere environment.

10. Low power consumable, exquisite structure and light weight, it is the ideal tube furnace for material research labs, also used in factory for small production.

Technical Parameters:

| Model | CMT1200-80IT+ |

| Product Name | 1200.C Rail-Sliding Tube Furnace |

| Chamber Material | High quality alumina fiber refractory insulation |

| Heating Element | High quality resistance wire |

| Max.temperature | 1200.C |

| Working Temperature | ≤1100.C |

| Heating Rate | ≤20.C /min |

| Heating Zone | Single |

| Length of Heating Zone | 400mm |

| Constant

Temperature Zone |

260mm |

| Tube Material | High purity quartz |

| Tube Size | D80*L1400mm

(other optional sizes: 60*1000mm & 80*1000mm) |

| Sealing Mode | Vacuum Flange |

| Control Mode | 7 inch color touch screen high precision intelligent controller,PID auto control, 30 segments programmable. |

| Operating Interface | English Graphical Interface |

| Temperature Accuracy | +/- 1.C |

| Presetting Curve | 15 presetting curve to avoid the trouble caused by repeated settings of different experimental processes |

| Protection Setting | Over temperature alarm, over current protection, broken thermocouple protection |

| Thermocouple | K Type |

| Working Voltage | 220V 50/60HZ(as required) |

| Power | 4KW |

| Dimension | 1400(L) * 520(W) * 640(H)mm |

| Warranty | 12 months, lifetime support |

| Certificate | CE, ISO |

Applications:

Rapid Annealing

Rapid Sintering