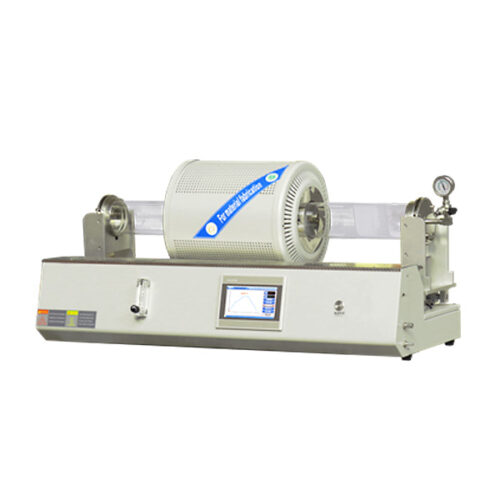

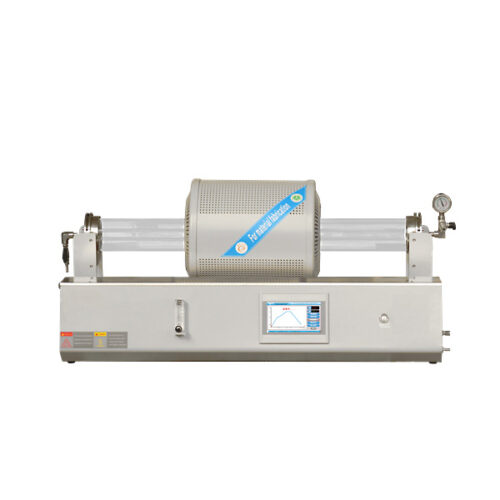

Saturated Steam Vertical Oxidation Quenching Furnace

Introduction:

This specialized Saturated Steam Vertical Oxidation Quenching Furnace is designed for universities, research institutes, and industrial enterprises to conduct oxidation experiments on metal materials under a certain saturated steam pressure. It uses PLC control and touch screen operation, allowing for easy initiation of preset experimental programs with a simple touch. It is particularly suitable for repetitive experiments or standard operating procedures, significantly improving work efficiency.

Features and Benefits:

1. Electric Lifting Device: Adjustable speed allows for rapid heating and cooling, quenching, and cold-hot fatigue experiments under atmospheric protection.

2. Platinum Suspension Wire: Enables sample suspension for sintering at temperatures up to 1500°C.

3. High-Efficiency Steam Generator: Facilitates oxidation experiments in a saturated steam environment.

4. Electric Claw: Allows for easy automatic sample release, with a maximum gripping force of 40N.

5. Stable and Reliable Control: Easy to operate.

6. Advanced PID Fuzzy Control: High temperature control precision, maintaining within ±1°C.

7. High-Purity Alumina Lightweight Fiber Material: Used in the furnace lining for better insulation and energy saving.

8. Data Storage Function: Can store important sintering parameters for up to 30 days (assuming 8 hours of operation per day).

9. Recipe Function: Can store over 100 preset recipes.

10. Multiple Safety Features: Ensures safe operation for users.

11. Network Capability: Connects to a host computer via RJ45 interface using TCP/IP protocol (host computer software required).

Technical Parameters of Quenching Furnace:

| Model | LT1700-60TIFN High-Temperature Oxidation Vertical Quenching Furnace |

| Max. temp | 1700℃ |

| Working temp | 800-1600℃(continuing) |

| Rated power | 12KW |

| Steam Generator Power | 800W + 150W heating tape |

| Thermocouple | B type |

| Heating element | High-purity silicon molybdenum rods(MoSi2) |

| Heating Zone Dimensions | 120*120*500mm |

| Furnace Body Dimensions | L 1005*H 2750* D 650mm |

| Furnace Tube Dimensions | Corundum Φ60*1200mm |

| Max Evaporation Rate | 10ml/min |

| Inlet Method | One-way float flow meter 0.1-0.8L/min |

| Quenching Tank Dimensions | Φ129*220mm |

| Recommended Heating Rate | ≤10℃/min |

| Control System | 1.Sintering Process Curve Setting: Dynamically displays the set curve. The equipment can store multiple sintering process curves, each of which can be freely set.

2. Scheduled Sintering: Enables unattended sintering process curve sintering. 3. Real-Time Display and Data Recording: Displays and records real-time sintering power, voltage, and other information, which can be exported for paperless recording. 4. Remote Control: Allows remote operation and real-time observation of equipment status. 5. Temperature Correction: Nonlinear correction of the difference between main control temperature and sample temperature throughout the sintering process.

|

| Electric Lift Device | Adjustable speed allows for rapid temperature increase and decrease, quenching, and cold-hot fatigue experiments under atmospheric protection.

|

| Platinum Suspension Wire | Allows for sample suspension and sintering at temperatures up to 1500°C. |

| Steam Generator and Quenching Tank | 1.Equipped with a high-efficiency steam generator for oxidation experiments in a saturated steam environment.

2.Quenching tank – quickly transfer samples to the quenching tank after heating to the appropriate temperature.

|

| Heating Elements | High-purity silicon molybdenum(MoSi2) rods. |

| Temperature Accuracy | ±1℃ |

| Sealing System | Stainless steel vacuum sealing flange |

| Vacuum Level | 10Pa (mechanical pump) |

| Gas Supply System | Uses a float flow meter to control gas flow rate, integrated with the equipment, and tested for leaks before delivery. |

| Pressure Measurement and Monitoring | Uses a mechanical pressure gauge with an airtight case to protect internal components from environmental influences and debris, offering strong resistance to corrosion and high temperatures. |

| Weight | 260 kg |

| Service Support | One-year limited warranty with lifetime support (the warranty does not cover consumable parts such as process tube and O-rings, which should be ordered as replacement parts under related products). |

Applications:

This specialized Saturated Steam Vertical Oxidation Quenching Furnace is designed for universities, research institutes, and industrial enterprises to conduct oxidation experiments on metal materials under a certain saturated steam pressure.