Advanced Plasma-Enhanced Chemical Vapor Deposition PECVD Furnace System for Precision Plasma Deposition

Introduction

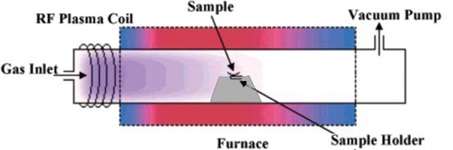

The advanced PECVD (Plasma-Enhanced Chemical Vapor Deposition) Furnace System is composed of a solid-state ion source, a gas proton flow control system, a substrate temperature control system, and a vacuum system. It utilizes operating software with centralized bus control technology.

This system is suitable for the deposition of SiO2 and SiNx thin films under conditions ranging from room temperature to 1200°C. Additionally, it can achieve deposition using TEOS as a source, deposit SiC film layers, and deposit other materials using liquid and gaseous sources. It is particularly well-suited for the efficient deposition of protective layers on organic materials and the deposition of inert films at specific temperatures without damage.

Key Features of PECVD Furnace System

- One-step coating and cleaning process to prevent secondary contamination.

- Top-open structure for easy observation of test samples.

- Fully automated control with a touchscreen and digital display.

- High degree of equipment integration.

- Stable radio-frequency power supply, uniform temperature distribution, enhancing film quality.

Technical Parameters

| Model | PECVD -1200-80

|

||||||||

| Power supply | AC220V 4KW | ||||||||

| Max.temp | 1200 ℃ | ||||||||

| Continuing temp | 1100℃ | ||||||||

| Heating rate | ≤ 20 ℃/min | ||||||||

| Radio-Frequency Power Supply | 300/500W 13.56MHz | ||||||||

| Tube size | Φ80*1200mm | ||||||||

| Deposition Schematic |  |

As shown in the diagram: This is a schematic representation of the deposition process in the equipment. | |||||||

| Control system |  |

1.Interactive graphical user interface with embedded operating system, featuring a 7-inch full-color touchscreen input, intelligent human-machine dialogue mode, real-time display of heating power, and nonlinear temperature correction. Experiment reports are autonomously generated, and experimental data can be exported an unlimited number of times.

2.The experimental process is more intuitive, and the operation is more convenient. 3.Equipped with functions such as over-temperature alarm, thermocouple disconnect alert, and leakage protection. |

|||||||

| Temperature accuracy | +/- 1 ℃ | ||||||||

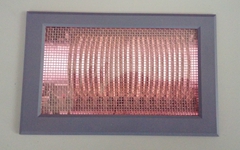

| Heating element |  |

High quality Fe-Cr-Al alloy doped with Mo | |||||||

| Sealing system |  |

|

|

||||||

| Vacuum level:≤10Pa(Mechanical Pump) | |||||||||

| Pressure Measurement and Monitoring |  |

Utilizing a digital vacuum gauge enhances the visual representation of the equipment’s vacuum level, providing a more intuitive understanding and ensuring greater accuracy in experimental results. | |||||||

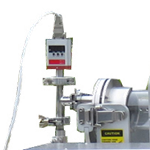

| Gas supply system |  |

Two sets of proton flow meters are employed to precisely control gas flow rates, seamlessly integrated into the equipment for enhanced functionality. | |||||||

| Dimension & Weight |

360KG |

||||||||

| Warranty | One year, lifetime support(Consumable parts such as processing tubes, o-rings are not covered by the warranty, please order replacements at related products below) | ||||||||

Applications

The advanced Plasma-Enhanced Chemical Vapor Deposition (PECVD) Furnace system is widely utilized in various industries and research fields for diverse applications. Here are some common applications:

Semiconductor Manufacturing

PECVD is extensively used in the semiconductor industry for depositing thin films on silicon wafers. It is employed in the fabrication of integrated circuits, microelectromechanical systems (MEMS), and other semiconductor devices.

Solar Cell Production

PECVD plays a crucial role in the manufacturing of thin-film solar cells. It is used to deposit various layers, such as amorphous silicon or silicon nitride, contributing to the efficiency and performance of solar panels.

Optical Coatings

PECVD is utilized for applying thin films on optical components like lenses and mirrors. It helps enhance the reflectivity, anti-reflective properties, and durability of optical coatings.

Flat Panel Display Manufacturing

PECVD is employed in the production of flat panel displays, including liquid crystal displays (LCDs) and organic light-emitting diode (OLED) displays. It is used to deposit thin films that enhance the performance and characteristics of display technologies.

Microelectronics and MEMS Devices

PECVD is crucial in the fabrication of microelectronics and MEMS devices. It is used to deposit insulation and passivation layers, as well as sacrificial layers in MEMS processes.

Barrier Coatings

PECVD is used to deposit barrier coatings that prevent the diffusion of gases or contaminants. This is important in applications where maintaining a specific environment or preventing corrosion is critical.

Biomedical Applications

In biomedical research, PECVD is employed to coat substrates with bio-compatible materials. This can include creating surfaces for cell culture, drug delivery systems, or bio-sensors.

Gas Barrier Films

PECVD is used to create gas barrier films, which are crucial in packaging materials to prevent the permeation of gases such as oxygen and moisture. This is important in preserving the quality and shelf life of food and pharmaceutical products.

Hard Coatings

PECVD is utilized to deposit hard coatings on materials, providing enhanced wear resistance and durability. This is applicable in cutting tools, automotive components, and various industrial applications.

Decorative Coatings

PECVD is employed for decorative coatings on glass and other materials. It enhances aesthetics while providing functional properties like scratch resistance.

The versatility of PECVD systems makes them indispensable in advancing technology and innovation across a broad spectrum of industries.