Multi-Temperature Zone CVD System

Introduction:

Multi-Temperature Zone Integrated CVD System, with flexible combinations of gas supply and vacuum systems, meets various film deposition needs. It is the most widely used technology in the semiconductor industry for depositing thin film materials, including large-area insulating materials, as well as most metal and metal alloy materials. Our complete CVD coating system is suitable for major university materials laboratories, research institutes, environmental science, and other fields.

Features of Multi-Temperature Zone CVD System:

- Utilizing high-purity quartz or stainless steel furnace tubes with excellent corrosion resistance and high-temperature performance.

- High-purity Al2O3 fiber refractory insulation material, providing superior insulation and reducing equipment power consumption.

- The furnace body employs a double-layer air-cooling structural design, with an automatic lifting system for opening the top cover.

- Sintering process curve settings: Dynamically display and set curves, allowing the pre-storage of multiple sintering processes. Each process curve can be freely configured.

- Scheduled sintering allows for unmanned operation, implementing scheduled sintering process curves.

- Real-time display of sintering power, voltage, and other information, recording sintering data, and enabling paperless documentation export.

- Capable of remote control to observe equipment status in real-time.

- Temperature calibration: Non-linear correction is conducted throughout the entire sintering process based on the temperature difference between the main control temperature and sample temperature.

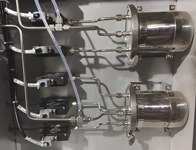

- The integrated equipment includes a multi-channel gas supply system, multi-temperature zone heating system, and high-vacuum system.

Technical Parameters:

| Product name | Multi-temperature zone CVD system

|

|||||||||||

| Temperature zone | Three | Four | Five | Six | ||||||||

| Tube size | Ø25/Ø50/Ø60/Ø80/Ø100*1600mm | |||||||||||

| Working temperature | ≤1150℃ | |||||||||||

| Heating zone optional

(Customizable) |

200mm*3

/200+300+200mm /200+400+200mm /300mm*3 /300+400+300mm |

200mm*4

/ 200+300+300+200mm /200+400+400+200mm /300mm*4 /300+400+400+300mm |

200mm*5

300mm*5

|

200mm*6

300mm*6

|

||||||||

| Heating rate | ≤20℃/s | |||||||||||

| Power supply | 6~10KW AC380V | 8~14KW AC380V | 10~15KW AC380V | 12~18KW

AC380V |

||||||||

| Gas system(Optional) | Float or proton(Float or mass flow meter (MFC)) | |||||||||||

| Piping Diagram |  |

|

||||||||||

| Quantity of Inlet ports | 2、3、4(Multiple Options Available) | |||||||||||

| Flow Range | 20-250/20-800ml/min……( Multiple range optional)

50/100/200/500sccm……( Multiple range optional) |

|||||||||||

| Operating Pressure Differential Range | 0-0.15MPa | |||||||||||

| Low Vacuum System(Optional) | Vacuum model | 3C / 4C | ||||||||||

| Pumping rate | 3L/s or 4L/s | |||||||||||

| Inlet and Outlet Port Dimensions | KF16/25 | |||||||||||

| Vacuum level of the system | 3~5Pa(Ultimate Vacuum Level of the Vacuum Pump:6.2*10-2Pa) | |||||||||||

| Operating Environment Temperature | 5-40℃ | |||||||||||

| Power supply | AC220V | |||||||||||

| High Vacuum System(Optional) | Vacuum model | 103(A) | 103(B) | |||||||||

| Pumping rate | 110L/s | 600L/s | ||||||||||

| Vacuum Gauge | Compound Vacuum Gauge | |||||||||||

| Vacuum level of the system | 4.3*10^-3Pa | 6*10^-4Pa | ||||||||||

| Operating Environment Temperature | 5-40℃ | |||||||||||

| Power supply | AC 220V | AC 380V | ||||||||||

Applications:

The applications of a multi-temperature zone Chemical Vapor Deposition (CVD) system are diverse and span various industries. Here are some common applications:

Semiconductor Fabrication;

Material Science Research;

Solar Cell Production;

Optoelectronics;

Chemical and Biological Sensors;

Microelectronics and Nanotechnology;

Coating and Surface Modification;

Research and Development;

Thin Film Deposition;

Photovoltaics;

Medical Devices;

Aerospace and Defense;

Energy Storage, etc.