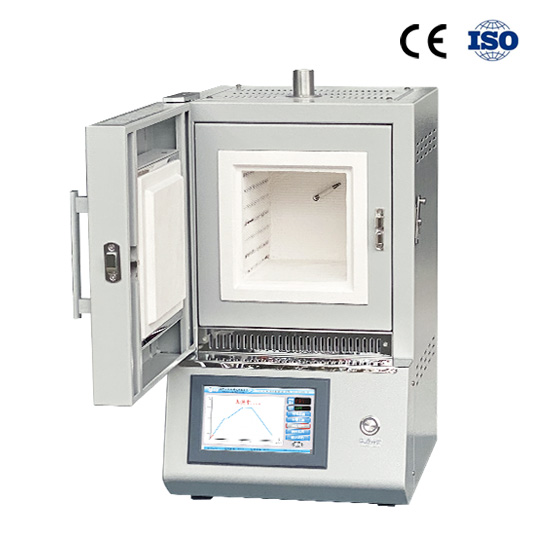

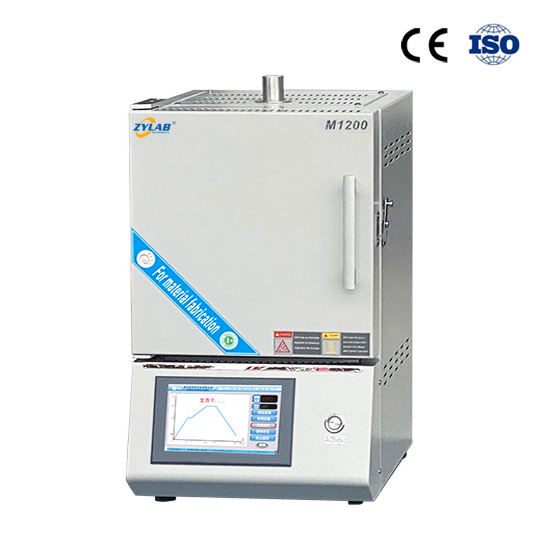

ZYLAB 1200°C Muffle Furnace for 3D Printing

Introduction

ZYLAB 1200°C Muffle Furnace for 3D Printing is a high-performance, cost-effective sintering solution designed for ceramic additive manufacturing. With precise temperature control and uniform heating, this mid-temperature furnace is ideal for sintering 3D printed ceramic components in research labs, universities, and industrial environments.

Equipped with a user-friendly 7″ touchscreen controller, a multilayer alumina fiber chamber, and a top-mounted exhaust system, this furnace ensures clean processing, efficient heat distribution, and safe operation. Multiple chamber sizes are available to support various experimental needs.

Key Features

- Max Temperature 1200°C: Working range: RT to 1100°C—suitable for mid-temperature sintering of 3D printed ceramics.

- 7-Inch Smart Touchscreen Controller: Intuitive UI, real-time temperature tracking, and programmable temperature curves to eliminate redundant manual settings.

- 30-Segment Programmable Control: Fully automatic, customizable heating profiles for precise thermal treatment.

- High-Efficiency Ceramic Fiber Chamber: Constructed with multilayer alumina insulation for rapid heating and energy savings.

- Premium Heating Components: Equipped with corrosion-resistant alloy heating wires to minimize contamination and extend service life.

- Top Exhaust Chimney: Efficiently removes fumes and volatiles—ideal for wax burnout, ashing, and other lab applications.

- Dual-Layer Steel Housing with Cooling Fan: Keeps exterior temperature below 50°C, ensuring operator safety and extended equipment lifespan.

- Compact, Lightweight & Energy Efficient: Designed for lab benches or small-scale production use; a practical tool for R&D or ceramic sintering in industrial settings.

- Customizable Chamber Sizes (Optional): Available in multiple volumes to suit different workflows and material requirements.

Applications of Muffle Furnace for 3D Printing

-

Sintering of 3D printed ceramic parts

-

Debinding of ceramic green bodies

-

Wax burnout and ashing processes

-

High-temperature material testing

-

General heat treatment in research and small-scale production

Technical Specifications of 1200°C Muffle Furnace for 3D Printing

| Model | M1200-15 | M1200-20 | M1200-30 | M1200-40 |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) | |||

| Max. Power | 3KW | 4KW | 9KW | 15KW |

| Maximum Temperature | 1200°C (for ≤1 hour) | |||

| Continuous Working Temp | 1100°C (continuous) | |||

| Max Heating Rate | ≤20°C/min | |||

| Chamber Size | 150 × 150 × 200 mm | 200*200*300mm | 300*300*400mm | 400*400*500mm |

| Overall Dimensions | 390 (W) × 600 (H) × 430 (D) mm | 650(W)*520(H)*600(D)mm | 950(W)*1400(H)*870(D)mm | 1100(W)*1650(H)*1050(D)mm |

| Temperature Controller |  |

|

||

| Temperature Accuracy | ±1°C | |||

| Heating Element |  |

Mo-doped Fe-Cr-Al alloy heating wire | ||

| Atmosphere Protection Box(Optional) |  |

Designed to create a controlled atmosphere inside the chamber. Prevents oxidation, contamination, and undesired reactions during heating. Customizable sizes available. | ||

| Net Weight | 40 kg | 60 kg | 160 kg | 260 kg |

| Safety Notice |

|

|||

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |||

Why Choose ZYLAB?

ZYLAB combines modern thermal design with affordable pricing to deliver lab-grade performance at industrial value. Our furnaces are trusted worldwide by universities, research institutes, and additive manufacturing innovators.

FAQ-1200°C Muffle Furnace for 3D Printing

Q: Besides sintering 3D printed ceramic materials, what other high-temperature processes can a 1200°C muffle furnace handle?

A: A 1200°C muffle furnace is also suitable for a wide range of high-temperature applications such as ash content determination, material oxidation/reduction studies, thermal aging, heat treatment of metal samples, and organic material burnout. It is commonly used in universities, industrial labs, and quality control departments.

Q: Can the furnace be used for ashing or organic material decomposition?

A: Yes, the furnace includes a top exhaust chimney, making it ideal for ashing tests, wax burnout, and organic decomposition, where the removal of volatile gases is essential for safe and clean processing.

Q: Is this furnace suitable for continuous operation over long durations?

A: Absolutely. Thanks to the high-quality insulation, stable heating elements, and programmable temperature control, this muffle furnace can maintain stable temperatures over long cycles, which is beneficial for long-term material testing or thermal processing protocols.

Q: Can I run multiple samples at once in the chamber?

A: Yes, the chamber is large enough to accommodate multiple crucibles or ceramic sample trays, making it suitable for batch testing or multi-sample experiments.

Q: Can the furnace be equipped with an atmosphere protection system?

A: Yes, an optional atmosphere protection box can be added to the furnace. It helps create a controlled atmosphere during heating, protecting sensitive materials from oxidation, contamination, or chemical interactions with air. The box size can be customized according to your sample dimensions and application requirements.

For More Content

Please read our blog: Muffle Furnace Usage Guide

For More Options on Muffle Furnaces

Please visit our website [Muffle Furnaces]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]