MoSi2 Heating Element

Introduction

MoSi2 heating element refers to a type of heating element made from molybdenum disilicide (MoSi2) ceramic material. These heating elements are known for their high-temperature capabilities, excellent thermal shock resistance, and long service life.

Here are some key features and characteristics of MoSi2 heating elements:

High-Temperature Operation:

MoSi2 heating elements are designed to operate at extremely high temperatures, typically up to 1700 or 1800 degrees Celsius (3272 degrees Fahrenheit). They can provide rapid heating and maintain stable temperatures in demanding industrial applications.

Oxidation Resistance:

One of the notable advantages of MoSi2 heating elements is their exceptional oxidation resistance at high temperatures. They form a protective layer of quartz (SiO2) on their surface when exposed to air or oxygen, which acts as a barrier against further oxidation and helps extend the element’s lifespan.

Fast Heating and Cooling:

MoSi2 heating elements have low thermal mass, which enables them to heat up and cool down rapidly. This characteristic makes them suitable for applications requiring quick temperature changes or precise temperature control.

Long Service Life:

MoSi2 heating elements have a prolonged operational lifespan due to their high-temperature stability and resistance to thermal cycling and chemical attacks. They can withstand frequent on/off cycles and harsh operating conditions, reducing the need for frequent replacements.

High Power Density:

MoSi2 heating elements offer high power density, meaning they can generate significant heat output in a relatively small space. This feature makes them advantageous for applications that require compact heating solutions or localized heating zones.

Clean and Non-Contaminating:

MoSi2 heating elements do not introduce impurities or contaminants into the heated environment, making them suitable for use in applications that require clean heating, such as semiconductor manufacturing, sintering processes, and heat treatment in the electronics industry.

Notes:

It’s important to note that MoSi2 heating elements are generally not suitable for reducing atmospheres or applications involving strong acids or alkalis. They are primarily used in oxidizing or inert atmospheres to ensure their longevity and optimal performance.

Overall, MoSi2 heating elements are favored for their high-temperature capabilities, oxidation resistance, and long service life, making them valuable components in high-temperature industrial heating processes.

Applications:

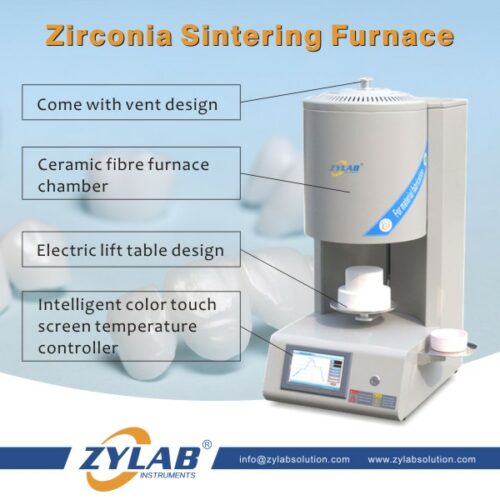

MoSi2 heating elements find applications in various industries, including ceramics, glass, metallurgy, heat treatment, research laboratories, and industrial furnaces. They are commonly used for applications such as sintering, annealing, brazing, and melting processes.

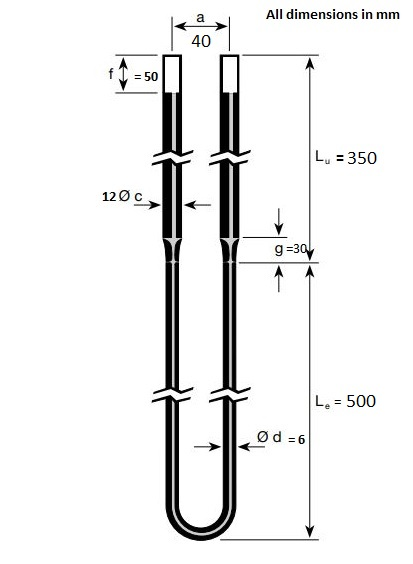

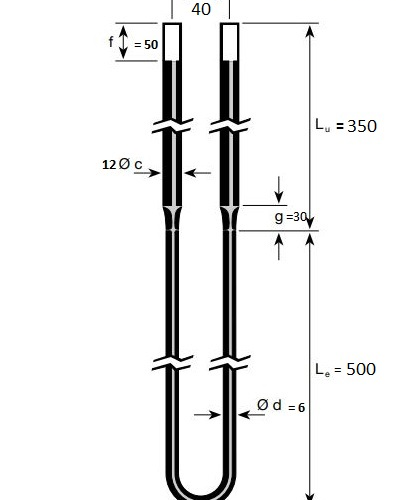

When ordering, please indicate the following data:

D1=diameter of hot zone

D2= diameter of cold zone

Le=length of hot zone

Lu=length of cold zone

A=distance between two cold zones