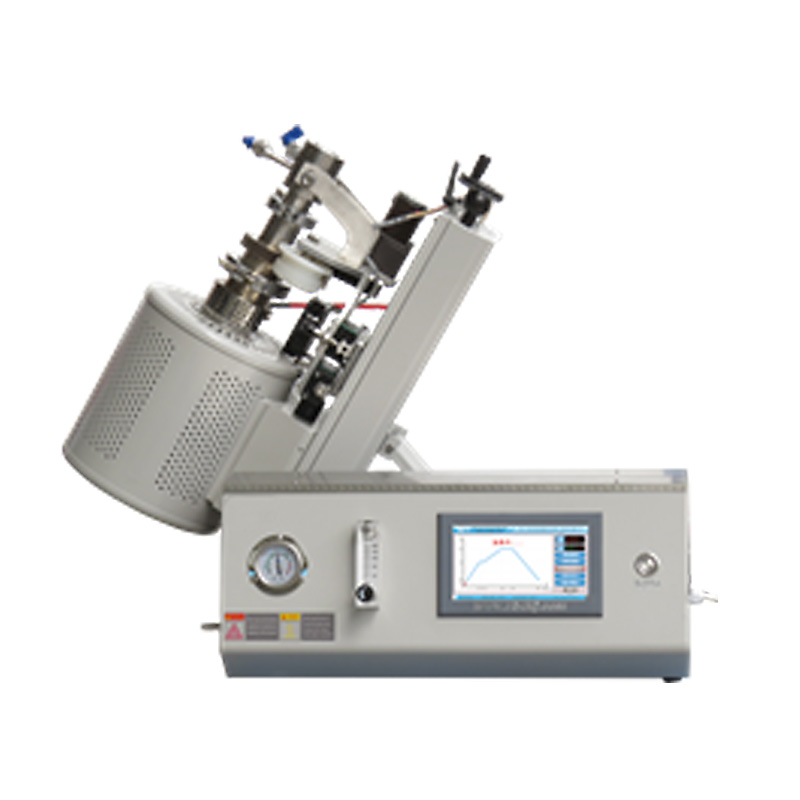

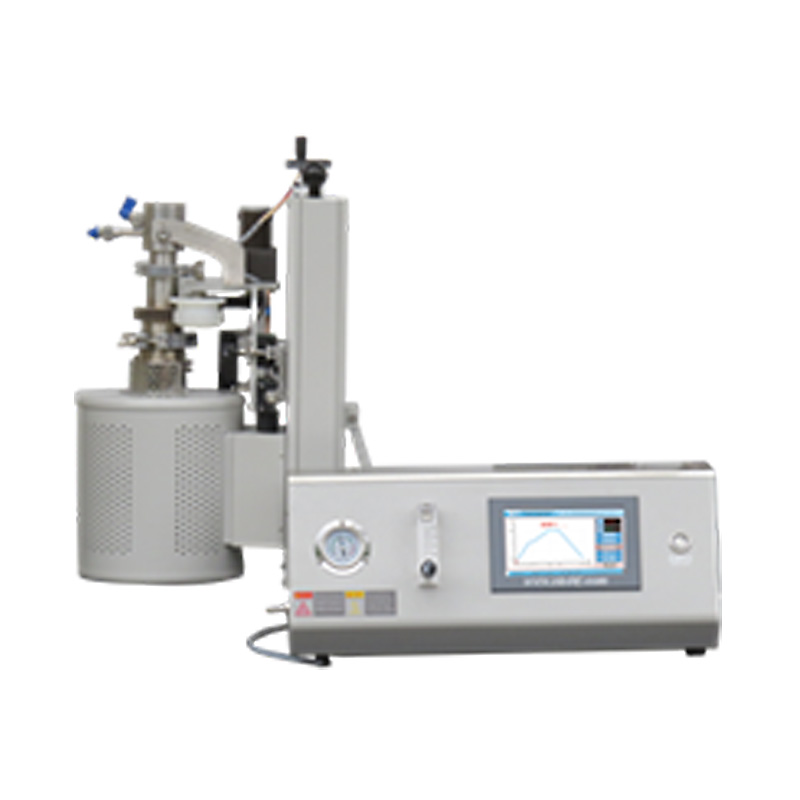

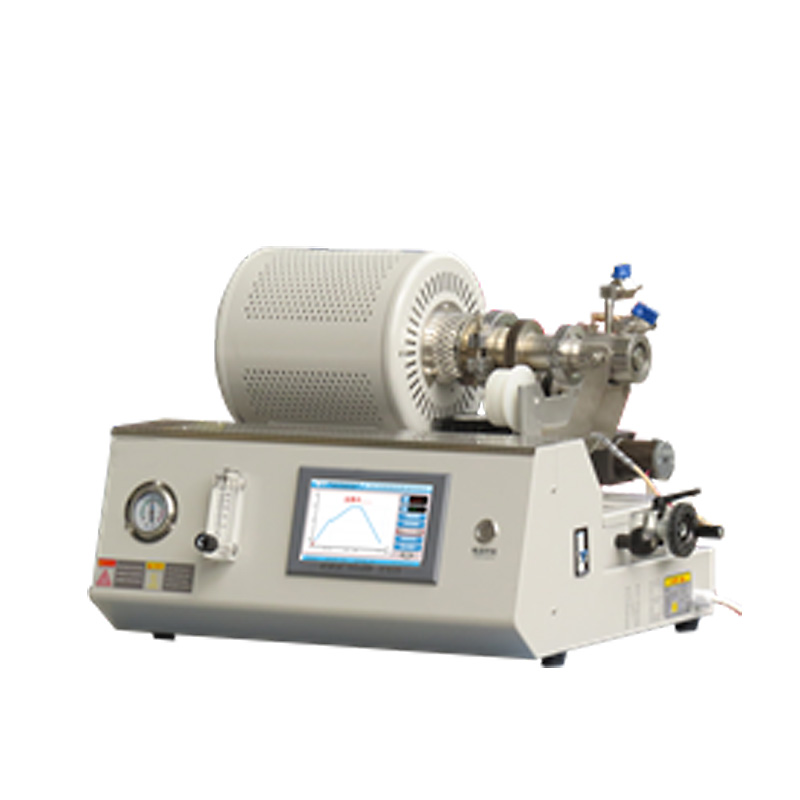

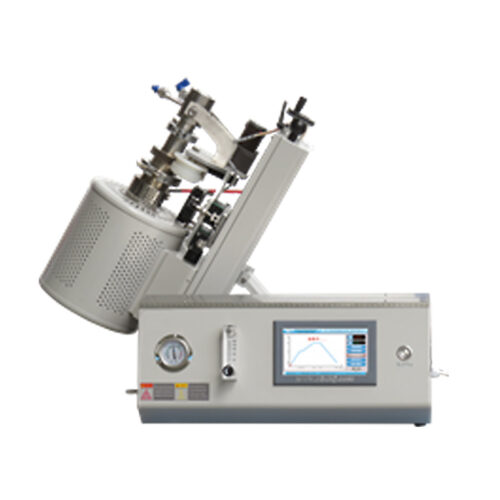

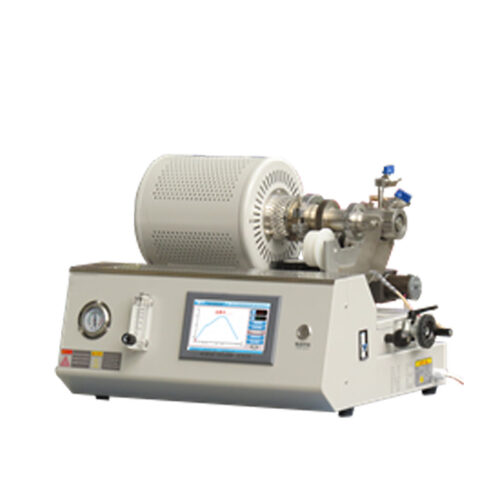

Mini Stirring Sintering Furnace

Introduction

Mini Stirring Sintering Furnace is suitable for experimental processes involving heat treatment of various materials. It finds applications in diverse industries such as rare earth preparation, electronic lighting, crystal annealing, bio-ceramics, electronic ceramics, special alloys, magnetic materials, precision casting, etc. This furnace is primarily utilized for processes like vacuum sintering, atmosphere-protected sintering, vacuum coating, CVD experiments, material composition analysis, and other related applications.

Features and Benefits

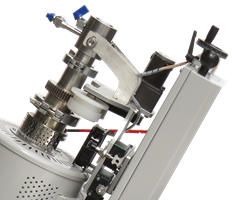

1.By means of uniform rotation, the material can be heated and come into contact with the gas more thoroughly and evenly.

2.Utilizing high-purity Al2O3 fiber refractory insulation material for energy efficiency and reduced consumption.

3.The high-purity alumina coating extends the service life of the heating element.

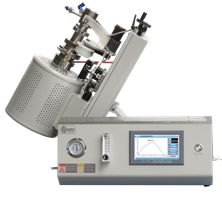

4.Adjustable at four angles (30 degrees, 45 degrees, 60 degrees, 90 degrees), facilitating easy replacement of the furnace tube.

Technical Parameters

| Model | RT1200-50TI

|

||||||

| Power supply | AC220V 1.2KW | ||||||

| Max.temp | 1200.C (<1 hour) | ||||||

| Working temp | 1100.C(Continuing) | ||||||

| Rotating speed (min) | Can be adjusted by yourself | ||||||

| Heating rate | ≤ 10 .C/min | ||||||

| Furnace Heating zone | φ80*100mm | ||||||

| Tube size | Φ50×220mm(One end sealed) | ||||||

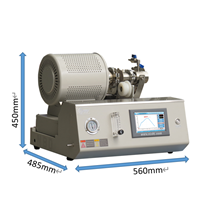

| Dimension of furnace | L560*H450*D485mm

|

||||||

| Effective volume | 70ml (tilted at 90 degrees) 48ml (tilted at 60 degrees)

33ml (tilted at 45 degrees) 17ml (tilted at 30 degrees) |

Calculate the isothermal zone based on a length of 50mm. | |||||

| Control system |  |

1.Capable of storing 15 temperature profiles, avoiding the inconvenience of repetitive setup for different experimental processes. 2.The experimental process is more intuitive, and the operation is more convenient. 3.The embedded operating system features a bilingual graphical interface (English and Chinese), a 7-inch full-color touchscreen input, an intelligent human-machine dialogue mode, and non-linear sample temperature correction. 4.Equipped with functions such as over-temperature alarm, thermocouple disconnection alert, and leakage protection. |

|||||

| Temp accuracy | +/- 1 ℃ | ||||||

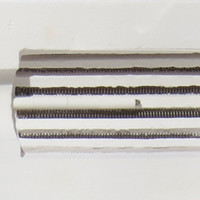

| Heating element |  |

Molybdenum-Doped Fe-Cr-Al Alloy High-Temperature Heating Wire | |||||

| Sealing system |  |

||||||

| Vacuum level:≤10Pa (Mechanical Pump) | |||||||

| Pressure Measurement and Monitoring |

|

Utilizing a mechanical pressure gauge with shock-absorbing oil to introduce damping effects during pressure fluctuations, reducing the back-and-forth oscillation of the pointer. | |||||

| Weight | 20KG | ||||||

| Warranty | One-year warranty, lifetime support (excluding consumable parts such as furnace tubes, O-rings ) | ||||||

Applications

This mini stirring fintering furnace finds applications in diverse industries such as rare earth preparation, electronic lighting, crystal annealing, bio-ceramics, electronic ceramics, special alloys, magnetic materials, precision casting, etc. This furnace is primarily utilized for processes like vacuum sintering, atmosphere-protected sintering, vacuum coating, CVD experiments, material composition analysis, and other related applications.

For Video

Please visit our youtube https://www.youtube.com/watch?v=goyyLnELnOI

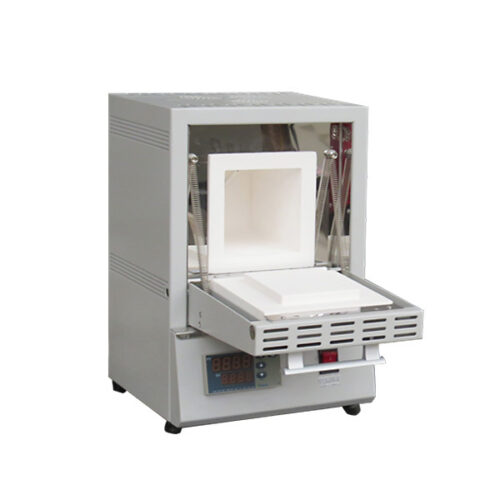

For More Options on High Temperature Furnaces

Click here [High Temperature Furnaces Collection]