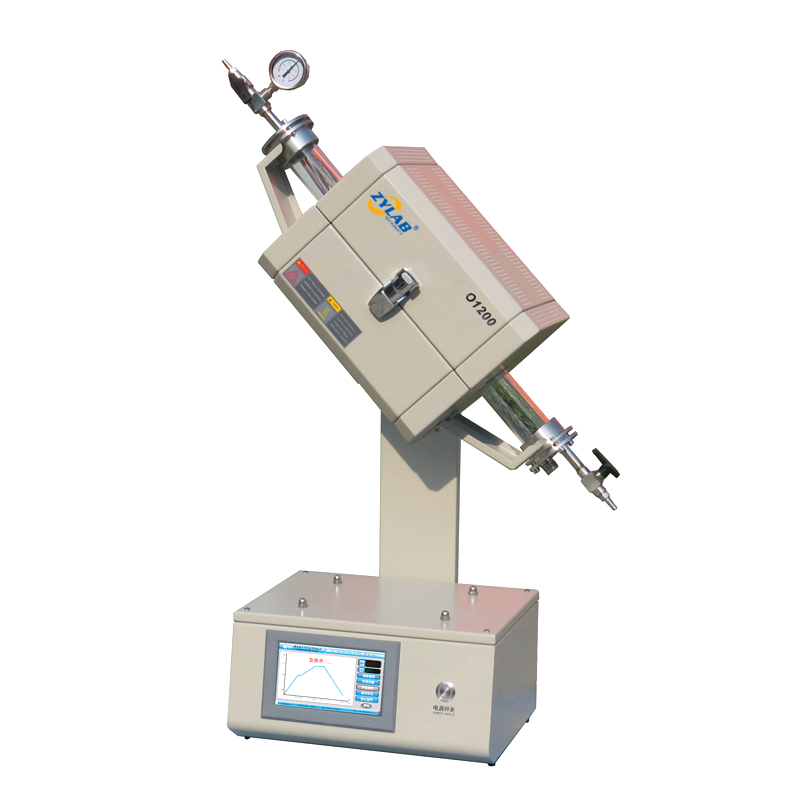

Laboratory Mini Rotary Tube Furnace

Introduction

The lab mini rotary tube furnace is a compact high-temperature processing device specifically designed for laboratory environments. It is particularly suitable for experiments requiring material synthesis, heat treatment, annealing, and other processes under controlled atmospheres or vacuum conditions. A key feature of this equipment is its unique rotatable design, allowing the furnace body to rotate 90 degrees along its axis. Additionally, its miniaturized design makes it ideal for laboratories with limited space.

Features

- Rotatable Design

- 90-Degree Rotation: The furnace body can rotate 90 degrees along its axis, enabling operation in multiple positions and facilitating easy loading and unloading of samples.

- Precise Temperature Control

- PID Regulation: Equipped with an advanced PID temperature controller to achieve precise temperature regulation, ensuring heating curves align with preset parameters.

- High-Precision Sensors: Integrated high-precision temperature sensors provide real-time monitoring of internal temperature changes, ensuring stable and reliable process conditions.

- Vacuum and Atmosphere Control

- Vacuum Pump System: Compatible with an efficient vacuum pump system to evacuate the furnace to the required vacuum level, enabling heating processes in oxygen-free or specific atmospheres.

- Atmosphere Control System: Allows the introduction of inert gases (e.g., argon, nitrogen) as needed to maintain a stable atmosphere, preventing sample oxidation or undesired reactions.

- Compact and Portable Design

- Space-Saving: The compact footprint minimizes space usage, making it highly suitable for laboratories with spatial constraints.

- Portability: Lightweight and easy to relocate, ideal for flexible experimental setups.

Technical Parameters

| Model | O1200-50 |

| Product Name | 1200.C Multi-position Tube Furnace |

| Chamber Model | Open |

| Chamber Material | Imported high quality alumina fiber refraction insulation |

| Heating Element | High quality resistance wire |

| Max.temperature | 1200.C |

| Working Temperature | RT-1100.C(continuing) |

| Heating Rate | 1℃/H-20℃/Min |

| Heating Zone | Single |

| Length of Heating Zone | 200mm |

| Constant

Temperature Zone |

120mm |

| Tube Material | High purity quartz |

| Tube Diameter | 50mm(Inner diameter 42mm) |

| Tube Length | 600mm |

| Sealing Mode | Vacuum Flange |

| Control Mode | 7 inch Touch Screen, Intelligent PID Control |

| Operating Interface | English Graphical Interface |

| Temperature Accuracy | +/- 1.C |

| Presetting Curve | 15 Presetting Curve, 30 Segments Programmable |

| Protection Setting | Over Temperature Alarm, Over Current Protection, Broken Thermocouple Protection |

| Thermocouple | K Type |

| Certification | CE, ISO |

| Working Voltage | AC 208-240V 50/60 Hz |

| Power | 1.2KW |

| Dimension | 380(L) * 350(W) * 450(H)mm |

| Net Weight | 23kgs |

| Standard Accessories | Quartz Tube, Vacuum Flange, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book |

Applications of Mini Rotary Tube Furnace

The Mini Rotary Tube Furnace is a piece of experimental equipment for heat treatment of various materials, which are mainly used in vacuum sintering, atmosphere protection sintering, vacuum coating, CVD experiments, material composition measurement Analysis and other occasions, such as:

- Powder Calcination and Sintering

- Heat treatment of ceramic, metal, and composite powders

- Phase transformation and densification of materials

- Enhancing the crystallinity of functional powders

- Nanomaterial and Catalyst Research

- Synthesis of nanoparticles under controlled temperature and atmosphere

- Catalyst activation and regeneration

- Thermal decomposition of precursors for catalyst preparation

- Battery Material Processing

- Annealing and calcination of cathode/anode materials for lithium-ion batteries

- Surface modification and coating of battery powders

- Precursor drying and solid-state reactions for energy storage materials

- Chemical Vapor Deposition (CVD) and Gas-Solid Reactions

- Thermal CVD for thin film deposition

- Gas-phase reactions for material synthesis

- Controlled atmosphere treatment for oxidation/reduction

- Metal and Alloy Processing

- Reduction of metal oxides to metallic powders

- Thermal treatment of fine metal powders for improved properties

- Controlled oxidation for oxide layer formation

- Polymer and Composite Processing

- Pyrolysis of polymeric materials

- Carbonization of polymer-derived materials

- Synthesis of composite materials through thermal processing

- Pharmaceutical and Biomaterial Research

- Heat treatment of bio-ceramic materials

- Sintering of bone scaffolds and biomaterials

- Controlled thermal decomposition for pharmaceutical synthesis

- Environmental Applications

- Waste treatment and pyrolysis of organic materials

- Decomposition of hazardous compounds

- CO2 capture and sorbent regeneration experiments

For More Options on Rotary Furnaces

Please visit our website [Rotary Furnaces Collection]