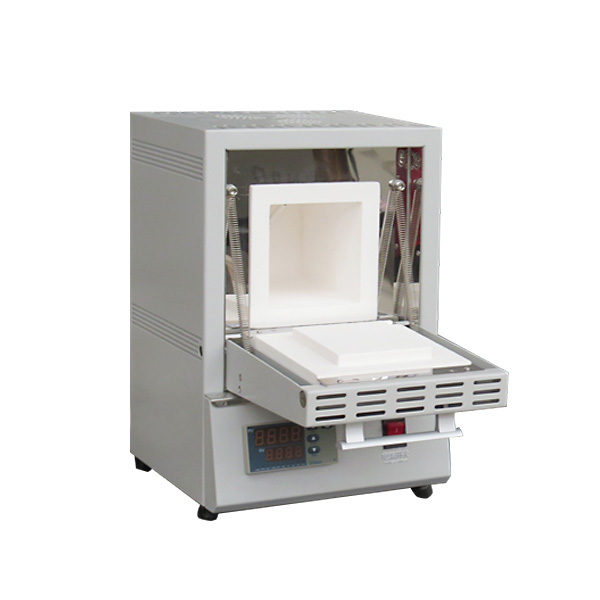

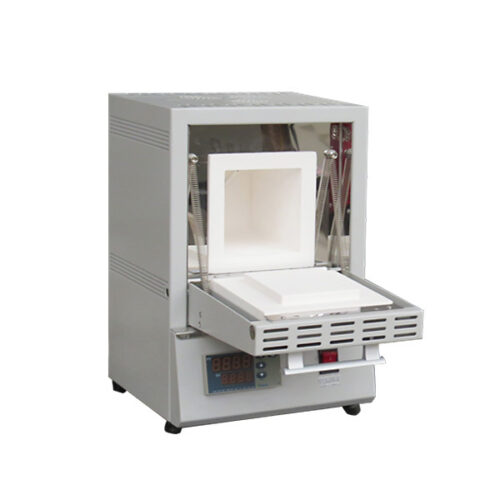

Laboratory Corrosion-Resistant Mini Muffle Furnace

Introduction:

The corrosion-resistant mini muffle furnace features a fully enclosed alumina fiber chamber with embedded heating elements and a sealed armored thermocouple, enhancing the longevity of the heating elements and preventing high-temperature emissions from affecting experimental results.

Its scientifically designed pull-down door structure allows for safe removal of materials, which can be placed directly on the furnace door, preventing burns on the workbench. With its elegant appearance and compact size, this furnace is widely used in university and research institute laboratories. It can be directly placed into a glove box through a large transition chamber, with three-sided uniform heating that effectively enhances the temperature uniformity within the furnace chamber.

Features and Benefits:

- Fully enclosed alumina fiber chamber with embedded heating elements and a sealed armored thermocouple.

- Small size and lightweight, easily placed into a glove box through a large transition chamber, saving laboratory space.

- Advanced refractory insulation materials with low heat loss, effectively reducing equipment power consumption.

- Suitable for a variety of material heat treatment and sintering processes.

Technical Parameters of Mini Muffle Furnace:

| Model | ML1200-10CI (Corrosion-Resistant Type) |

| Power Supply | AC220V 1KW |

| Maximum Temperature | 1200°C (<1 hour) |

| Continuous Temperature | 1100°C (continuous) |

| Heating Rate | ≤20°C/minute |

| Furnace Chamber Size | 100*100*100mm(1L) |

| Control System | 1. Fuzzy PID temperature control, high-brightness digital display;

2. Programmable for 30 segment “time-temperature” curves; 3. Features include over-temperature alarm, thermocouple disconnection prompt, and leakage protection.

|

| Temperature Accuracy | +/- 1°C |

| Heating Element | Fully enclosed alumina fiber chamber with embedded heating elements and a sealed armored thermocouple.

|

| Net Weight | Approximately 10KG |

| Service Support | 1-year warranty with lifetime support (warranty does not cover consumable parts). |

Appllications:

- Ceramic Processing

- Burnout

- Sintering

- Annealing

- Calcination

- Material Science Research

- Material Development: Essential for research laboratories focused on developing new materials with specific properties.

- Thermal Analysis: Useful for conducting thermal analysis experiments.

- Synthesis of Advanced Materials: Facilitates the synthesis of advanced materials like composites, nanomaterials, and specialty alloys.

- Metallurgy

- Heat Treatment of Metals

- Phase Transformation Studies: Useful for studying phase transformations in metals and alloys at high temperatures.

- Metal Powder Processing: Can be used in the sintering and calcination of metal powders for various applications.

- Chemical Analysis

- Ashing: Suitable for ashing organic and inorganic samples to determine their composition.

- Loss on Ignition (LOI) Tests: Used for LOI tests to measure the amount of moisture and volatile substances in materials.

- Decomposition of Complex Materials: Helps in the decomposition of complex materials to simpler forms for analysis.

- Environmental Testing

- Soil Testing: Used in soil testing laboratories for the thermal treatment of soil samples to study their composition and contamination levels.

- Waste Material Analysis: Essential for analyzing the composition of waste materials and determining the presence of hazardous substances.

- Pharmaceutical Industry

- Thermal Stability Studies: Helps in studying the thermal stability of pharmaceutical compounds and excipients.

- Electronics and Semiconductor Industry

- Wafer Processing: Useful for various heat treatment processes involved in semiconductor wafer fabrication.

- Component Testing: Can be used for testing the thermal stability and performance of electronic components.

- Education and Training

- Academic Research: Widely used in universities and educational institutions for research and practical training in materials science, chemistry, and engineering.

- Laboratory Exercises: Provides a hands-on tool for students to learn about high-temperature processes and material properties.