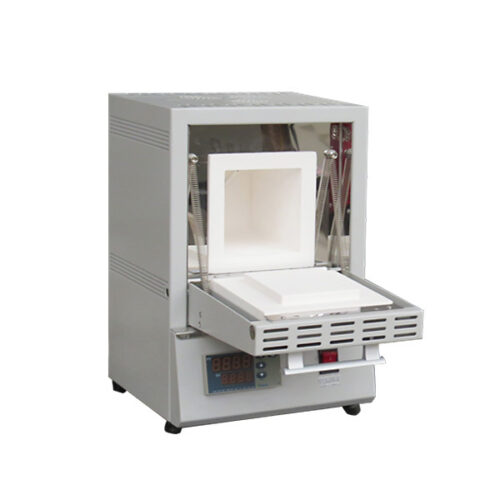

Mini Hydrogen Reduction Furnace

Introduction:

This Mini Hydrogen Reduction Furnace incorporates safety features such as pressure monitoring within the furnace tube, providing functions like gas cutoff and temperature reduction. Additionally, it has the capability to ignite and treat combustible tail gases, with a dual ignition protection system in place to ensure the complete combustion of discharged gases. When used in conjunction with a tubular furnace, it can also automatically clean and replace gases within the furnace tube for optimal performance.

Features of Mini Hydrogen Reduction Furnace:

- Automatic cycling for vacuum cleaning and gas delivery.

- Dual automatic igniters at the exhaust end, ensuring one is active while the other is in standby for protection, guaranteeing thorough combustion of combustible gases and stable equipment operation.

- Pipeline self-extinguishing anti-flashback device, rigorously controlling the backflow of combustible gases.

- Multiple working modes are available for selection, and customization options are also available upon request.

- Embedded operating system with an interchangeable graphical interface in both Chinese and English. The 7-inch true-color touchscreen allows for intelligent human-machine dialogue, featuring a non-linear temperature correction pattern.

Technical Parameters:

| Model | 2AQD

|

||

| Control system |  |

||

| Interface size | 1/4” Double Ferrule Connector | ||

| Pipeline Pressure | -0.1-0.15MPa | ||

| Weight | 20KG + 20KG(Furnace) | ||

| Service Support | One-year warranty with lifetime support (consumables not included within the warranty scope). | ||

| Applictations | Material Science Research; Nanomaterial Synthesis; Catalyst Activation; Laboratory Scale Experiments; Educational Purposes; Metal and Alloy Research; Powder Metallurgy; Specialized Heat Treatment, etc |

||

Detail Applications:

A hydrogen reduction furnace is a specialized high-temperature device used for reduction reactions, where hydrogen gas acts as a reducing agent to convert oxides into their corresponding metals or other reduced forms. Here are the main applications of hydrogen reduction furnaces:

- Metal Powder Production: In powder metallurgy, hydrogen reduction furnaces are often used to reduce metal oxides to pure metal powders. These powders are used in applications like 3D printing, hard alloys, and magnetic materials.

- Magnetic Material Preparation: In the production of rare earth magnetic materials, such as neodymium-iron-boron (NdFeB), hydrogen reduction furnaces are used to reduce rare earth oxides to their corresponding metals, facilitating the creation of high-performance magnetic materials.

- Ceramic Materials: Hydrogen reduction furnaces are used in the sintering and reduction treatment of certain ceramic materials to improve their electrical conductivity and mechanical properties.

- Catalyst Preparation: In the chemical industry, hydrogen reduction furnaces are utilized to prepare metal catalysts, especially when high-purity and highly active metals are required.

- Semiconductor Materials: These furnaces are used in semiconductor manufacturing for the purification and doping of semiconductor materials like silicon and germanium.

- Surface Treatment: The furnace can be used for the reduction treatment of metal surfaces, removing oxide layers or improving surface properties.