Split-Type Mini Crucible Furnace for Lab Use

Introduction:

This mini crucible furnace is specifically designed for glove boxes, it can easily pass through the transfer chamber into the glove box.

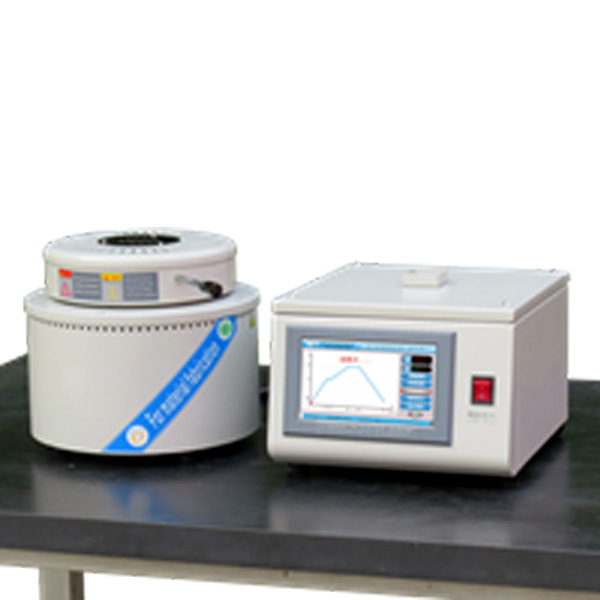

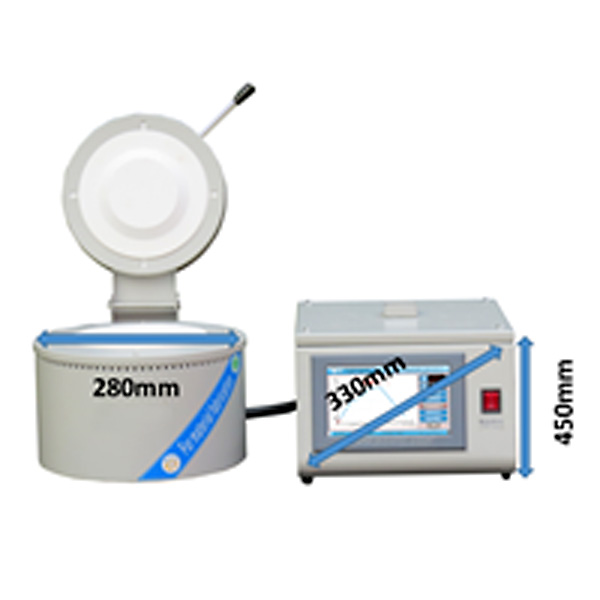

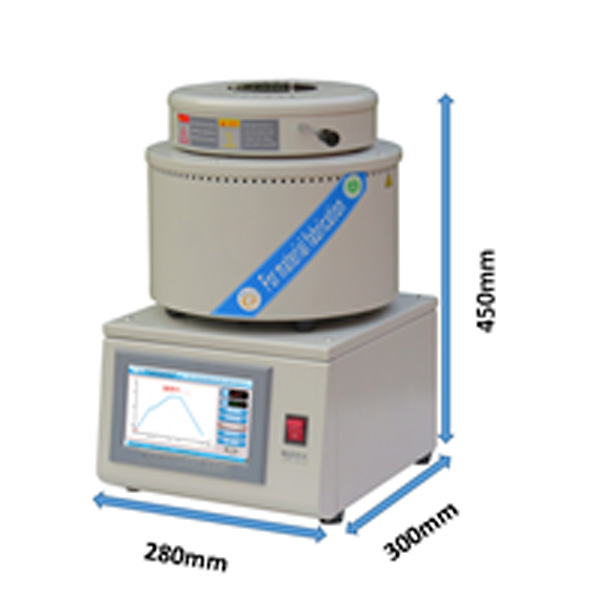

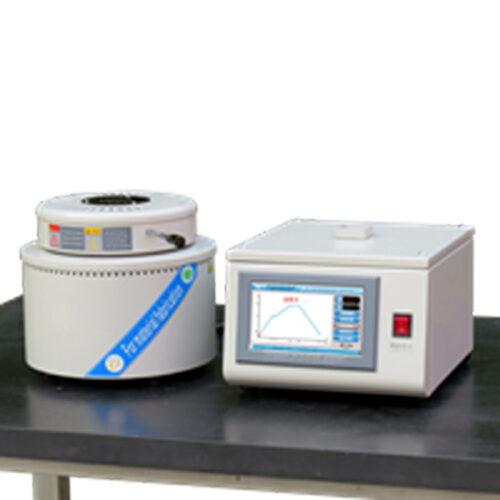

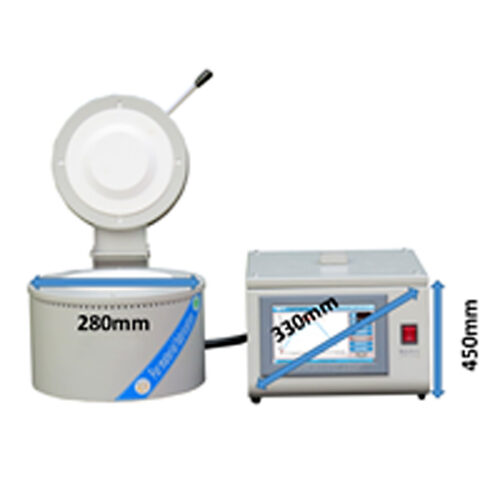

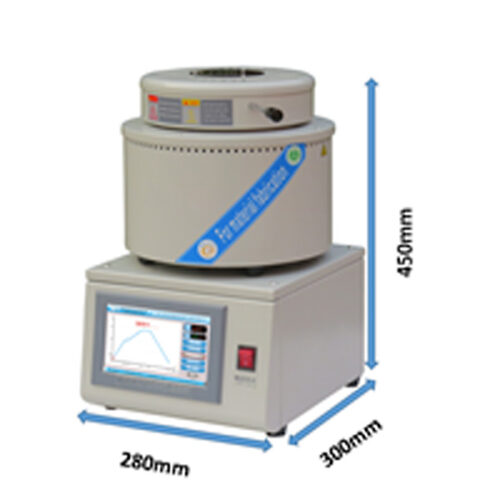

The heating section and touchscreen control system can be stacked or placed flat based on experimental requirements.

The heater with high purity quartz protection sleeve, features a multi-turn ring design, which ensures cleanliness in the heating chamber, uniform temperature distribution, and prolongs the lifespan of the heating elements.

Features and Benefits:

1. Uses a contactless SCR (Silicon Controlled Rectifier) module, enhancing system control stability.

2. The furnace chamber is equipped with a ring-shaped distribution of alloy heating wire, ensuring uniform temperature distribution inside the chamber.

3. Made from vacuum-formed refractory insulation material with minimal heat loss, effectively reducing power consumption.

4. Modular design, durable and easy to maintain.

5.Touchscreen interface for intuitive display of temperature curves.

Technical Parameters:

| Model | ZYLAB-G1200-10IT |

| Power Supply | AC220V, 1.2KW |

| Max.temp | 1200°C |

| Continuous Temperature | 1100°C (continuous operation) |

| Heating Rate | ≤ 20°C/min |

| Furnace Chamber Size | Φ100*100mm |

| Control System | 1. Embedded operating system with bilingual (Chinese/English) graphical interface, 7-inch true color touchscreen input, intelligent human-machine interaction mode, and nonlinear temperature correction.

2. Can store up to 15 temperature profiles, eliminating the need to repeatedly set parameters for different experimental processes. 3. Equipped with over-temperature alarm, thermocouple disconnection warning, and leakage protection.

|

| Temperature Accuracy | +/- 1°C |

| Heating Element | Mo-doped Fe-Cr-Al alloy with high purity quartz protection, ring-shaped heating chamber

|

| Service | 1 year warranty with lifetime support |

Which kinds of industry can use this Mini Crucible Furnace?

College & Universities, New Material Research, New Energy R&D, Powder Metallurgy, Electronics, Ceramic, Chemistry, Medicine,etc.

Applications of Mini Crucible Furnace:

- Metal Melting: Melting small amounts of metals for casting and sample preparation.

- Material Testing: Heat treatment and testing of materials to determine properties.

- Alloy Production: Small-scale alloy production and refining.

- Sintering & Firing: Sintering ceramics, powders, and other materials.

- Research & Development: Used in R&D labs for material experimentation.

- Heat Treatment: Processes like annealing of metals.

- Glass & Ceramic Firing: Firing small glass or ceramic samples.

- Metallography Sample Prep: Heating metal samples for microstructure analysis.

- High-Temperature Reactions: Researching combustion and other high-temp reactions.

For More Options on Crucible Furnace

Please visit our website [Crucible Furnaces Collection]