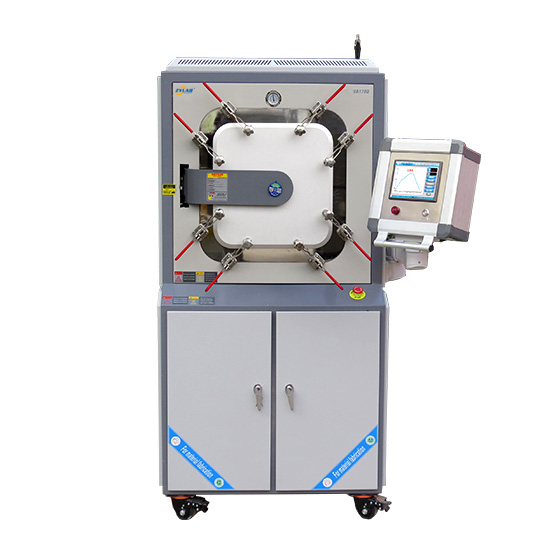

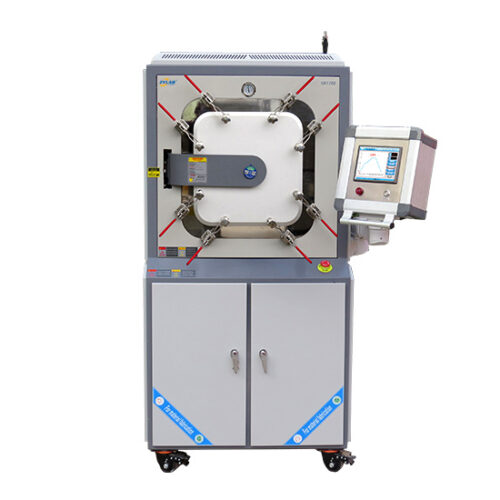

ZYLAB 1700°C Metal-Ceramic Debinding Furnace

Introduction

ZYLAB 1700°C Metal-Ceramic Debinding Furnace is a high-performance thermal processing system specifically designed for binder removal and sintering of metal and ceramic components produced through Metal Injection Molding (MIM), Ceramic Injection Molding (CIM), and 3D printing technologies.

This advanced furnace features a high-purity chamber, precise temperature control, and excellent uniformity, making it ideal for applications that require controlled atmosphere processing and high-temperature stability. The system supports both vacuum and gas atmospheres, ensuring maximum flexibility for various debinding requirements.

Key Features

-

1650°C High-Temperature Capability

Supports demanding debinding and sintering processes for metals and ceramics. -

Dual Atmosphere Operation

Compatible with vacuum and inert gas environments (argon, nitrogen), ensuring clean and controlled processing. -

Precise PID Temperature Control

Advanced fuzzy logic controller with ±1°C accuracy and multi-step programmable profiles. -

Uniform Heating with High-Efficiency Insulation

Alumina fiber insulation and optimized heating layout deliver fast heating and uniform temperature distribution. -

User-Friendly Interface

Touchscreen operation, curve display, auto-start, and real-time data logging for easy, intelligent control. -

Built-in Safety System

Includes over-temperature protection, gas pressure monitoring, and cooling system safeguards. -

Customizable Chamber Design

Furnace chamber size and structure can be tailored based on specific application needs.

Applications of Metal-Ceramic Debinding Furnace

The ZYLAB 1700°C debinding furnace is widely used in the thermal post-processing of parts manufactured via 3D printing, MIM, and CIM. It is especially effective in:

-

Binder removal and sintering of metal injection molded parts (e.g. stainless steel, titanium alloys)

-

Debinding and densification of ceramic parts (e.g. zirconia, alumina)

-

3D printed metal/ceramic part post-treatment

-

Sintering of composite materials including carbon fiber reinforced components

-

Research & development of high-performance structural materials

Technical Specifications

| Model | VA1700-30 | |

| Power Supply | AC 380V, 12KW | |

| Maximum Temperature | 1650°C | |

| Continuous Working Temp | 1600°C | |

| Furnace Chamber Size | 300 × 300 × 400 mm | |

| Vacuum Level | ≤100 Pa | |

| Recommended Heating Rate | ≤20°C/min | |

| Temperature Accuracy | ±1°C | |

| Heating Element |  |

High-purity MoSi₂ (molybdenum disilicide) rods |

| Control System |  |

|

| Optional Configuration |  |

Copper electrode feedthrough (vacuum-sealed, connects to external heating system) |

| Safety Notes |

|

|

| Support & Warranty | 1-year warranty (excluding consumables); lifetime technical support | |

FAQ – 1700°C Metal-Ceramic Debinding Furnace

Q: What types of additive manufacturing (3D printing) components is this furnace suitable for?

A: It is ideal for post-processing of metal and ceramic 3D printed parts, including stainless steel, titanium alloy, Inconel, and ceramic composites that require debinding and sintering.

Q: Can this furnace be used for binder removal and sintering in one cycle?

A: Yes. The furnace supports debinding under controlled atmosphere or vacuum followed by high-temperature sintering, which improves process efficiency for MIM and 3D printing applications.

Q: How does this furnace benefit additive manufacturing post-processing?

A: It enables stress relief, improved material density, and mechanical strength of printed parts while preserving dimensional accuracy, essential for functional end-use components.

Q: What atmosphere is recommended for metal part sintering?

A: An inert gas atmosphere such as argon is recommended for metals to prevent oxidation. The vacuum environment is also ideal for cleaner sintering results in certain alloys.

Q: Is it possible to customize the furnace chamber size or features?

A: Yes. ZYLAB offers customized furnace solutions based on specific sample sizes, materials, or process requirements.

Q: What is the warranty period and service policy?

A: ZYLAB provides a 1-year warranty (excluding consumables like sealing rings) and lifetime technical support.

For More Content

Please read our blog: Applications of Vacuum Furnaces in Materials Preparation: An In-Depth Guide

For More Options on Additive Manufacturing(3D Printing)

Please visit our website [Additive Manufacturing(3D Printing)]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]