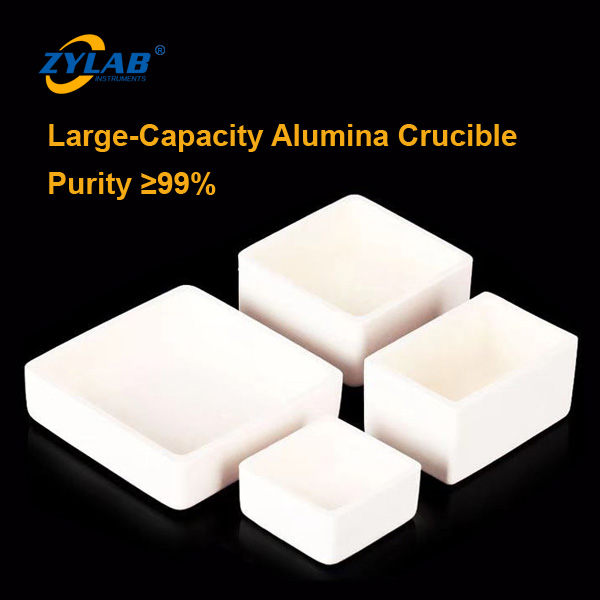

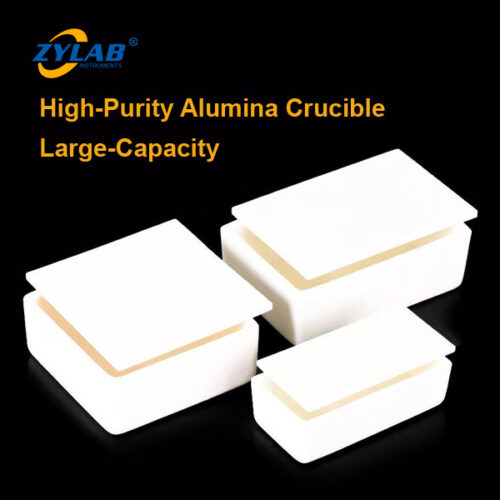

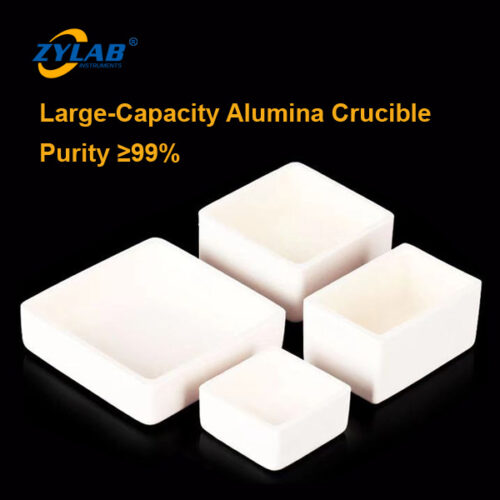

ZYLAB Large Capacity High-Purity Alumina Rectangular Crucible

Product Details:

ZYLAB Large Capacity Rectangular High-Purity Alumina Crucible is specifically designed for high-temperature applications, offering exceptional thermal stability, chemical resistance, and long-term durability. Engineered to meet the demands of scientific research, industrial processes, and material synthesis, this crucible features a large capacity design that maximizes sample volume and processing efficiency.

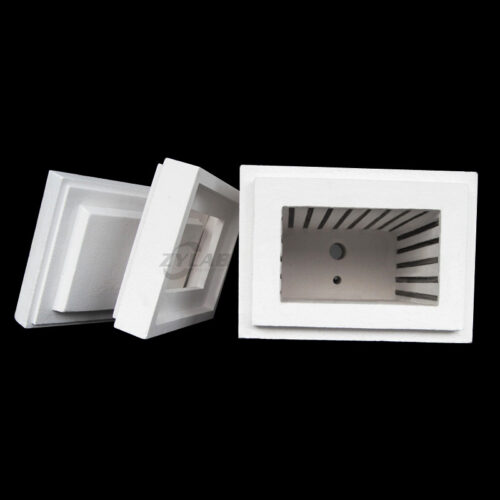

In addition to its robust construction, the crucible is available with customizable window openings, allowing for direct observation or gas flow adjustments during experiments. This flexibility makes it ideal for applications requiring in-situ monitoring or controlled atmospheric conditions.

Whether used in laboratory analysis, high-temperature heat treatment, or advanced material research, the ZYLAB rectangular alumina crucible guarantees reliable performance and customization to meet your specific needs.

Material: Alumina (Al₂O₃)

Purity: ≥99%

Shape: Rectangular , with or without Lid

Continuous operating temperature: ≤1600°C

Thermal Shock Resistance: Excellent performance under rapid heating and cooling cycles

Chemical Resistance: Inert to most acids, alkalis, and molten metals

Electrical Insulation: Superior dielectric properties at high temperatures

For more information, custom orders, or technical support, please contact us.

Applications

-

High-Temperature Heat Treatment: Ideal for annealing, calcination, and sintering processes.

-

Material Science Research: Suitable for the synthesis and thermal analysis of advanced materials.

-

Laboratory Melting and Analysis: Reliable for melting, fusing, and holding samples in high-temperature environments.

-

Semiconductor Industry: Used for wafer processing and other high-purity material treatments.

-

Battery Material Production: Efficient for processing cathode and anode materials.

Specifications for Large Capacity High-Purity Alumina Rectangular Crucible

| Large Capacity High-Purity Alumina Rectangular Crucible (UoM:mm) | |||

| 120×120×100 | 135×135×60 | 140×140×38 | 140×140×45 |

| 140×140×70 | 150×150×30 | 150×150×50 | 150×150×60 |

| 150×150×80 | 155×120×50 | 160×120×35 | 160×120×85 |

| 160×140×120 | 160×160×45 | 180×180×60 | 200×100×25 |

| 200×100×50 | 200×150×200 | 200×200×50 | 200×200×80 |

| 200×200×100 | 225×225×83 | 250×150×80 | 250×250×80 |

| 250×250×100 | 300×60×60 | 300×180×70 | 300×200×80 |

| 330×330×80 | 330×330×120 | 330×330×160 | |

Custom dimensions and shapes are available upon request.

If you need more detailed information, please contact us immediately. We offer free quotes on all products!

High Purity Alumina Crucibles Notes for Use:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.

FAQ

Q: Can the crucible handle rapid temperature changes?

A: The crucible is designed to resist thermal shock, but gradual heating and cooling are recommended to extend its lifespan.

Q: Are custom sizes available?

A: Yes, we offer size and capacity customization to meet specific application requirements.

Q: What industries use this type of crucible?

A: Common industries include semiconductor manufacturing, materials research, chemical analysis, and high-temperature material processing.

More Laboratory Crucibles

99% Alumina Conical Muffle Furnace Crucible with Lid

99% Alumina Square Crucible with Lid

Ceramic Crucible For Lab Muffle Furnace

Click to view the comparison of laboratory crucibles, including quartz, magnesium oxide, boron nitride, and graphite crucibles, to help you choose the right one for your experimental needs.